Kiln firing porcelain involves exposing the material to extremely high temperatures for several hours, ensuring durability, strength, and a flawless finish. Microwave firing, though faster and more energy-efficient, often results in uneven heating and weaker structural integrity. For high-quality, long-lasting porcelain, kiln firing remains the superior choice.

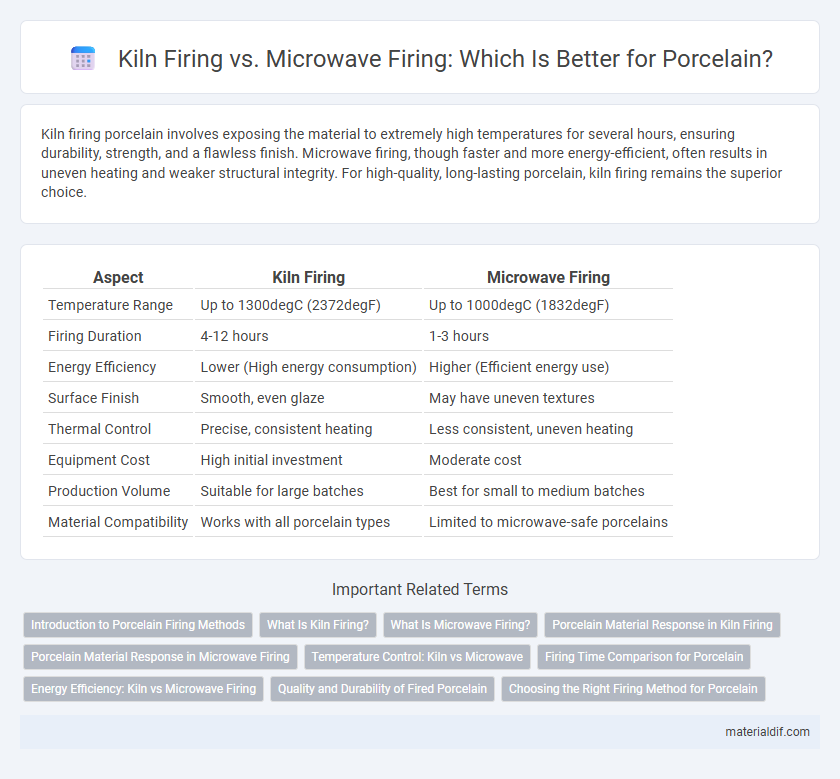

Table of Comparison

| Aspect | Kiln Firing | Microwave Firing |

|---|---|---|

| Temperature Range | Up to 1300degC (2372degF) | Up to 1000degC (1832degF) |

| Firing Duration | 4-12 hours | 1-3 hours |

| Energy Efficiency | Lower (High energy consumption) | Higher (Efficient energy use) |

| Surface Finish | Smooth, even glaze | May have uneven textures |

| Thermal Control | Precise, consistent heating | Less consistent, uneven heating |

| Equipment Cost | High initial investment | Moderate cost |

| Production Volume | Suitable for large batches | Best for small to medium batches |

| Material Compatibility | Works with all porcelain types | Limited to microwave-safe porcelains |

Introduction to Porcelain Firing Methods

Porcelain firing methods predominantly include kiln firing and microwave firing, each influencing the material's strength and translucency. Kiln firing, a traditional method, involves gradual heating to high temperatures around 1200-1400degC, allowing for optimal vitrification and durability. Microwave firing offers a faster alternative by using electromagnetic waves to heat porcelain rapidly, though it may result in variable surface qualities compared to kiln-fired pieces.

What Is Kiln Firing?

Kiln firing is a traditional ceramic process where porcelain is heated to high temperatures between 1,200degC and 1,400degC in a kiln, enhancing its strength, durability, and translucency. This method allows precise control over temperature and atmosphere, creating vitrification that solidifies the porcelain's microstructure. Unlike microwave firing, kiln firing produces consistent, high-quality results essential for fine porcelain production.

What Is Microwave Firing?

Microwave firing is a modern technique that uses microwave energy to heat porcelain rapidly and evenly, reducing the overall firing time compared to traditional kiln firing. This method leverages microwave radiation to excite water molecules and ceramics within the porcelain, achieving vitrification and strength without exposing the piece to prolonged high temperatures. Microwave firing offers enhanced energy efficiency and precise temperature control, making it an innovative alternative for pottery and porcelain production.

Porcelain Material Response in Kiln Firing

Porcelain responds to kiln firing with gradual, even heat that facilitates optimal vitrification, resulting in enhanced translucency and strength. The controlled temperature ramp-up in kiln firing prevents thermal shock and micro-cracking, preserving the integrity of the porcelain matrix. In contrast to microwave firing, kiln firing ensures consistent particle sintering and uniform glaze maturation, critical for high-quality porcelain finishes.

Porcelain Material Response in Microwave Firing

Porcelain's response to microwave firing differs significantly from kiln firing due to its unique thermal properties and moisture content. Microwave firing heats porcelain internally by agitating water molecules, which can cause uneven temperature distribution and potential cracking if moisture is trapped within the material. Traditional kiln firing ensures uniform thermal expansion and vitrification, resulting in stronger, more durable porcelain with fewer structural defects.

Temperature Control: Kiln vs Microwave

Kiln firing offers precise temperature control, essential for achieving the optimal vitrification point of porcelain, typically between 1200degC and 1400degC. In contrast, microwave firing provides rapid heating but lacks the uniform temperature distribution necessary for consistent porcelain strength and translucency. The controlled, gradual temperature increase in kilns minimizes thermal shock and ensures durable, high-quality porcelain results.

Firing Time Comparison for Porcelain

Kiln firing porcelain typically requires several hours at high temperatures, often between 1,200degC to 1,400degC, to achieve proper vitrification and durability. Microwave firing, while faster--taking minutes instead of hours--may not consistently reach the necessary temperature or uniform heating needed for optimal porcelain development. The significant difference in firing time impacts the final strength, translucency, and overall quality of the porcelain piece.

Energy Efficiency: Kiln vs Microwave Firing

Kiln firing porcelain consumes significantly more energy due to higher temperature requirements, typically between 1200degC and 1400degC, sustained over several hours. Microwave firing uses targeted, rapid heating that can reduce energy consumption by up to 50%, making it a more energy-efficient option for small-scale or experimental applications. However, kiln firing remains essential for larger batches and achieving consistent structural integrity in high-quality porcelain products.

Quality and Durability of Fired Porcelain

Kiln firing porcelain ensures optimal quality and durability due to the even, controlled high temperatures that promote proper vitrification and crystallization of the ceramic materials. Microwave firing often results in uneven heat distribution, leading to weaker structural integrity and potential flaws such as cracks or incomplete glaze maturation. Porcelain fired in traditional kilns exhibits superior hardness, resistance to chipping, and long-lasting stability compared to microwave-fired pieces.

Choosing the Right Firing Method for Porcelain

Selecting the right firing method for porcelain significantly affects its durability and finish. Kiln firing offers precise temperature control, reaching up to 1300degC (2372degF), which is essential for achieving the vitrification and strength characteristics typical of high-quality porcelain. Microwave firing, while faster and energy-efficient, is generally suited for small-scale or experimental pieces and may not provide the consistent heat distribution needed for standard-strength porcelain production.

Kiln Firing vs Microwave Firing Infographic

materialdif.com

materialdif.com