Porcelain enamel is a durable coating made by fusing powdered glass to a metal surface at high temperatures, creating a smooth, protective layer resistant to corrosion and wear. Porcelain glaze, on the other hand, is a glassy coating applied to ceramic items that vitrifies during firing, enhancing the piece's aesthetic appeal and making it waterproof. Both techniques involve high-temperature processes but serve different functional and decorative purposes in materials science and craftsmanship.

Table of Comparison

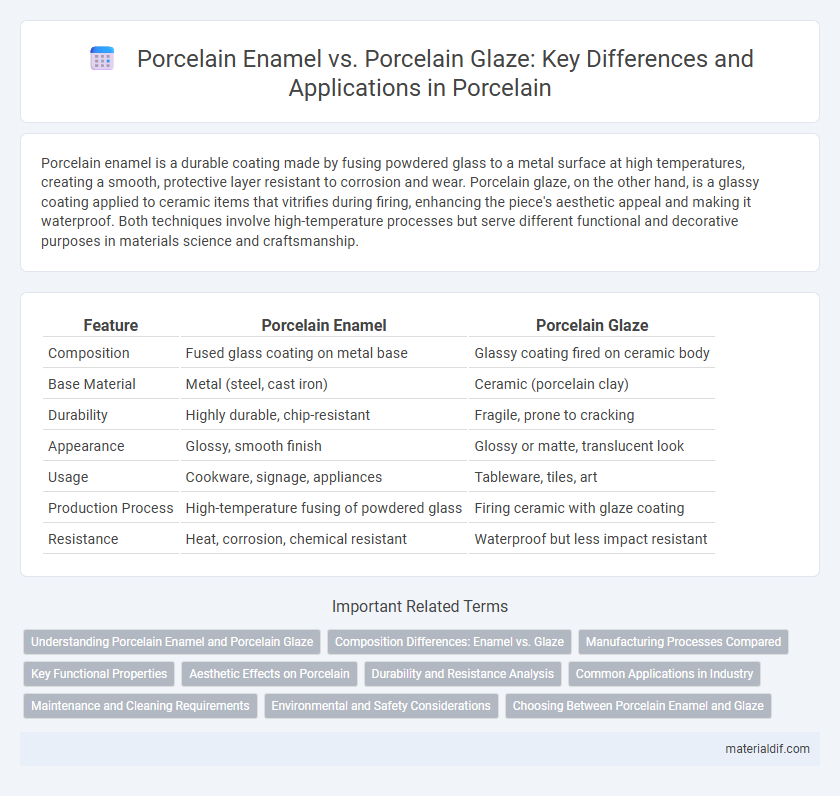

| Feature | Porcelain Enamel | Porcelain Glaze |

|---|---|---|

| Composition | Fused glass coating on metal base | Glassy coating fired on ceramic body |

| Base Material | Metal (steel, cast iron) | Ceramic (porcelain clay) |

| Durability | Highly durable, chip-resistant | Fragile, prone to cracking |

| Appearance | Glossy, smooth finish | Glossy or matte, translucent look |

| Usage | Cookware, signage, appliances | Tableware, tiles, art |

| Production Process | High-temperature fusing of powdered glass | Firing ceramic with glaze coating |

| Resistance | Heat, corrosion, chemical resistant | Waterproof but less impact resistant |

Understanding Porcelain Enamel and Porcelain Glaze

Porcelain enamel is a durable, glassy coating fused to metal surfaces through high-temperature firing, providing corrosion resistance and a smooth, glossy finish often used in cookware and industrial applications. Porcelain glaze, on the other hand, is a vitreous coating applied to ceramic items like porcelain pottery and tiles, creating a waterproof seal and enhancing aesthetic appeal with varied textures and colors. Understanding the distinct materials, application processes, and functional benefits helps differentiate porcelain enamel's metal-bonded coating from porcelain glaze's ceramic surface treatment.

Composition Differences: Enamel vs. Glaze

Porcelain enamel is a glassy coating composed primarily of powdered glass fused to metal surfaces through high heat, resulting in a smooth, durable finish resistant to corrosion and wear. In contrast, porcelain glaze consists of a mixture of silica, alumina, and fluxes applied to ceramic bodies, which, upon firing, forms a vitrified, impermeable layer that enhances both aesthetics and functionality. The key composition difference lies in enamel's metal-based substrate integration versus glaze's ceramic body fusion, influencing their application and durability.

Manufacturing Processes Compared

Porcelain enamel involves fusing powdered glass to a metal substrate through high-temperature firing, creating a durable, corrosion-resistant coating commonly used in cookware and industrial applications. Porcelain glaze, on the other hand, is a glassy coating applied and fired on ceramic bodies, forming a smooth, often decorative surface integral to porcelain pottery and tiles. The manufacturing process of porcelain enamel emphasizes metal preparation and controlled firing to ensure adhesion, while porcelain glaze production focuses on glaze formulation and precise kiln firing to achieve desired aesthetic and functional properties.

Key Functional Properties

Porcelain enamel offers exceptional durability and chemical resistance, providing a protective coating that enhances scratch and corrosion resistance on metal surfaces. Porcelain glaze, primarily applied to ceramic bodies, creates a glass-like, impermeable surface that improves aesthetic appeal and prevents water absorption. Both materials contribute to surface hardness and thermal stability, but porcelain enamel excels in mechanical protection while porcelain glaze emphasizes decorative finish and impermeability.

Aesthetic Effects on Porcelain

Porcelain enamel creates a durable, glass-like coating that enhances porcelain's surface with vibrant color and a glossy finish, improving resistance to scratches and stains. Porcelain glaze, applied as a thin, translucent layer, contributes to the smooth texture and depth of color, often highlighting intricate designs through its subtle sheen. Both methods influence the aesthetic appeal by altering light reflection and surface texture, but enamel achieves a more robust, multidimensional effect compared to the softer, refined look of glaze.

Durability and Resistance Analysis

Porcelain enamel exhibits superior durability and resistance due to its thick, glass-like coating fused at high temperatures, making it highly resistant to chipping, scratching, and corrosion compared to porcelain glaze. Porcelain glaze, while providing a smooth and glossy finish, generally forms a thinner layer that is more susceptible to wear and less effective against chemical damage. The enhanced hardness and chemical stability of porcelain enamel make it ideal for industrial applications requiring long-lasting protection and aesthetic maintenance.

Common Applications in Industry

Porcelain enamel is widely used in industrial applications such as cookware, appliances, and architectural panels due to its durability and resistance to corrosion. Porcelain glaze, primarily found on ceramics and decorative tiles, provides a smooth, glass-like finish that enhances aesthetic appeal and waterproofing. Both materials are essential in industries requiring long-lasting, heat-resistant, and visually appealing surfaces.

Maintenance and Cleaning Requirements

Porcelain enamel is a durable coating fused to metal surfaces, requiring minimal maintenance with simple cleaning using non-abrasive sponges and mild detergents to prevent damage to its glossy finish. In contrast, porcelain glaze, a glassy coating baked onto ceramic items, necessitates careful cleaning with soft cloths and gentle cleaners to avoid scratches and preserve its delicate surface. Both materials benefit from regular wiping and avoidance of harsh chemicals to maintain their aesthetic and functional qualities over time.

Environmental and Safety Considerations

Porcelain enamel, a durable coating applied to metal surfaces, offers superior resistance to chipping and corrosion, reducing the need for frequent replacements and minimizing environmental waste. Porcelain glaze, typically a silica-based glass layer fused onto ceramic bodies, involves higher energy consumption during firing but does not emit toxic substances, making it safer for indoor air quality. Both materials are non-toxic and inert once cured, posing minimal health risks, though porcelain enamel production may involve hazardous chemicals requiring careful handling to ensure worker safety.

Choosing Between Porcelain Enamel and Glaze

Porcelain enamel is a durable, glass-like coating fused to metal surfaces, providing high resistance to heat and corrosion, while porcelain glaze is a vitrified, smooth layer applied to ceramic bodies for aesthetic appeal and waterproofing. Choosing between porcelain enamel and glaze depends largely on the substrate and application requirements; enamel suits cookware and appliances needing toughness, whereas glaze enhances the appearance and functionality of ceramic pottery and tiles. Understanding these distinctions ensures optimal performance and longevity in various industrial and artistic contexts.

Porcelain enamel vs Porcelain glaze Infographic

materialdif.com

materialdif.com