Hard porcelain, also known as true porcelain, is fired at higher temperatures around 1,200-1,450degC, resulting in a dense, vitrified, and highly durable material ideal for fine dinnerware and decorative objects. Soft porcelain is fired at lower temperatures around 1,100-1,200degC, making it more porous, less dense, and slightly brittle but easier to shape and often used for sculptural or artistic ceramics. The primary differences lie in firing temperature, durability, translucency, and typical applications, with hard porcelain offering superior strength and water resistance.

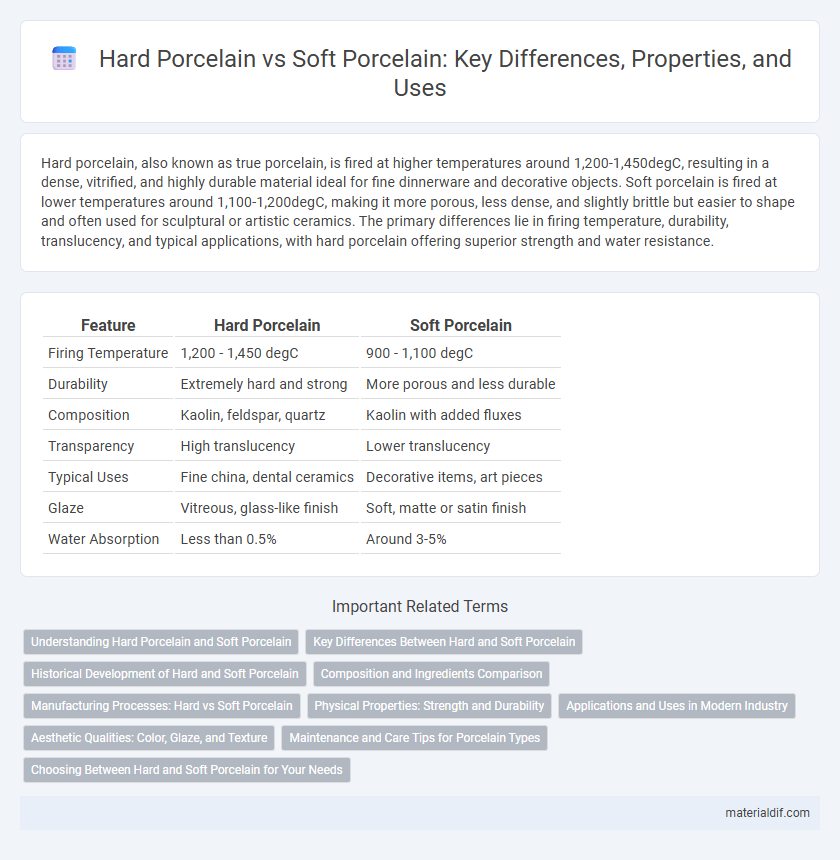

Table of Comparison

| Feature | Hard Porcelain | Soft Porcelain |

|---|---|---|

| Firing Temperature | 1,200 - 1,450 degC | 900 - 1,100 degC |

| Durability | Extremely hard and strong | More porous and less durable |

| Composition | Kaolin, feldspar, quartz | Kaolin with added fluxes |

| Transparency | High translucency | Lower translucency |

| Typical Uses | Fine china, dental ceramics | Decorative items, art pieces |

| Glaze | Vitreous, glass-like finish | Soft, matte or satin finish |

| Water Absorption | Less than 0.5% | Around 3-5% |

Understanding Hard Porcelain and Soft Porcelain

Hard porcelain is characterized by its dense, durable composition with a high firing temperature above 1,200degC, resulting in a vitrified, translucent body often used for fine dinnerware and artistic ceramics. Soft porcelain, fired at lower temperatures around 1,100degC, contains a higher proportion of glassy materials, making it more porous and less durable but easier to mold and decorate. Understanding these differences is essential for selecting the appropriate type based on the required strength, translucency, and decorative qualities in ceramic production.

Key Differences Between Hard and Soft Porcelain

Hard porcelain is characterized by a higher firing temperature, typically around 1,400degC, resulting in greater density, durability, and a vitrified, glass-like finish. Soft porcelain is fired at lower temperatures between 1,100degC and 1,200degC, which makes it more porous and less durable but easier to decorate with intricate designs. The key differences also include the composition: hard porcelain contains more kaolin and feldspar, while soft porcelain has higher levels of glassy phases, affecting translucency and strength.

Historical Development of Hard and Soft Porcelain

Hard porcelain, originating in 18th-century Europe, was developed through the fusion of kaolin and feldspar, resulting in a dense, durable material that became synonymous with fine tableware and decorative art. Soft porcelain, first produced in China during the Tang dynasty, predates hard porcelain and is characterized by its lower firing temperature and more porous, translucent quality, often used for intricate, delicate designs. The historical evolution of both types reflects technological advances in kiln design and material science, influencing global trade and cultural exchange in ceramics.

Composition and Ingredients Comparison

Hard porcelain consists primarily of kaolin, feldspar, and quartz, fired at a high temperature around 1,400degC, resulting in a dense, vitrified, and durable structure. Soft porcelain includes a higher proportion of clay mixed with feldspar and quartz but contains more fluxing agents, such as bone ash or other additives, and is fired at a lower temperature, approximately 1,200degC, leading to a more porous and less durable body. The key compositional difference lies in hard porcelain's higher kaolin and silica content contributing to its strength, while soft porcelain's increased flux and clay content produces a more translucent but fragile material.

Manufacturing Processes: Hard vs Soft Porcelain

Hard porcelain is produced by firing a mixture of kaolin, feldspar, and quartz at temperatures between 1,200degC and 1,450degC, resulting in a dense, vitrified body with high mechanical strength and translucency. Soft porcelain involves firing at lower temperatures, around 1,000degC to 1,200degC, using less kaolin and more clay, which yields a more porous and less durable product with a slightly softer texture. The manufacturing process of hard porcelain emphasizes high-temperature vitrification for durability, whereas soft porcelain relies on lower firing temperatures, allowing for easier shaping but reduced hardness and resistance.

Physical Properties: Strength and Durability

Hard porcelain, also known as hard-paste porcelain, exhibits higher strength and durability due to its dense vitrified structure formed at temperatures around 1400degC, making it resistant to chipping and wear. Soft porcelain, or soft-paste porcelain, fired at lower temperatures near 1200degC, is more porous and less robust, resulting in lower mechanical strength and increased susceptibility to damage. The superior composition and firing process of hard porcelain enhance its physical properties, ensuring longer-lasting performance in functional and decorative applications.

Applications and Uses in Modern Industry

Hard porcelain, known for its high durability and resistance to thermal shock, finds extensive use in industrial applications such as electrical insulators, laboratory equipment, and cookware. Soft porcelain, characterized by its lower firing temperature and greater porosity, is primarily utilized in decorative items, tableware, and certain artistic ceramics. Modern industry prefers hard porcelain for functional components requiring mechanical strength and chemical resistance, while soft porcelain suits aesthetic purposes where translucency and surface finish are prioritized.

Aesthetic Qualities: Color, Glaze, and Texture

Hard porcelain showcases a translucent, bright white color with a smooth, glass-like glaze that enhances its sleek texture and durability. Soft porcelain often features warmer, creamier tones and a softer, more matte glaze, creating a delicate texture that highlights intricate decorative details. The contrast in aesthetic qualities makes hard porcelain ideal for modern, minimalist designs, while soft porcelain suits classic, ornate styles.

Maintenance and Care Tips for Porcelain Types

Hard porcelain, known for its durability and dense composition, requires gentle cleaning with non-abrasive cloths and mild detergents to maintain its glossy finish without causing surface scratches. Soft porcelain, being more porous and delicate, benefits from careful handling, avoidance of extreme temperature changes, and cleaning with soft sponges and mild, pH-neutral cleaners to prevent chipping and discoloration. Both types should be stored in stable environments to minimize exposure to humidity and physical impact, ensuring their longevity and aesthetic appeal.

Choosing Between Hard and Soft Porcelain for Your Needs

Hard porcelain, known for its high firing temperature around 1400degC, offers exceptional durability, chip resistance, and a vitrified, glass-like surface ideal for heavy-use items like dinnerware and tiles. Soft porcelain, fired at lower temperatures around 1200degC, features a more porous, slightly translucent quality suited for decorative pieces and fine art objects that require delicate detailing. Selecting between hard and soft porcelain depends on your needs for strength and durability versus aesthetic finesse and elaboration.

Hard Porcelain vs Soft Porcelain Infographic

materialdif.com

materialdif.com