Porcelain tiles and porcelain slabs both offer durability and a sleek appearance, but porcelain slabs provide larger, seamless surfaces ideal for countertops and wall cladding, while porcelain tiles are better suited for flooring and smaller installations due to their manageable size. The installation process differs as slabs require specialized handling and support because of their size and weight, whereas tiles allow more versatility and easier replacement. Choosing between porcelain tile and slab depends on the project scale, aesthetic preferences, and structural requirements.

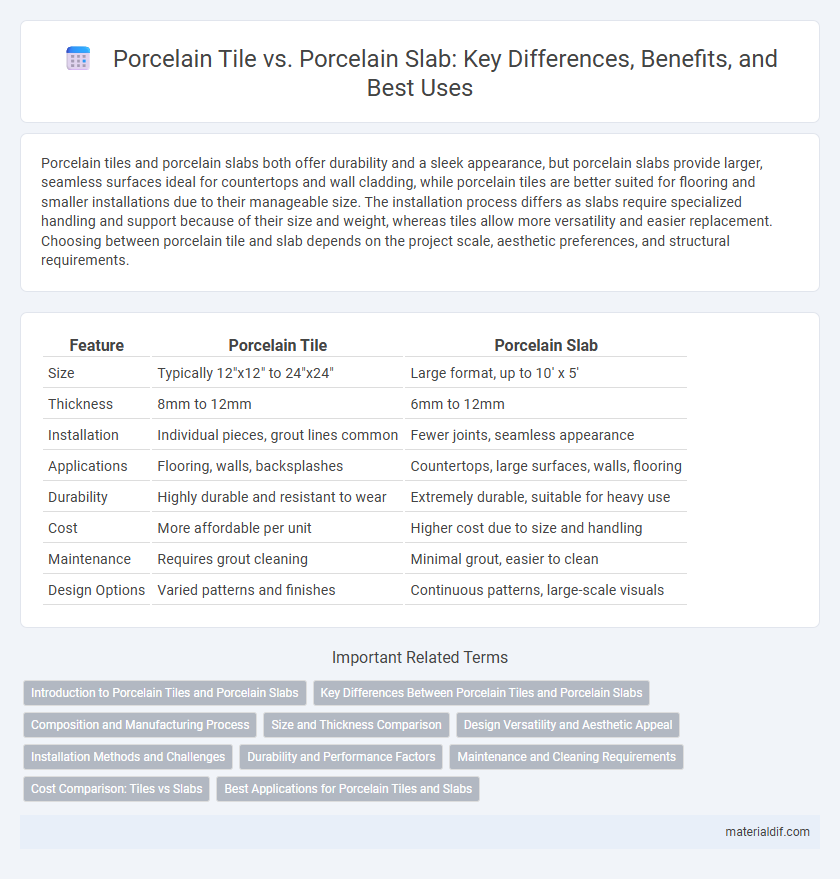

Table of Comparison

| Feature | Porcelain Tile | Porcelain Slab |

|---|---|---|

| Size | Typically 12"x12" to 24"x24" | Large format, up to 10' x 5' |

| Thickness | 8mm to 12mm | 6mm to 12mm |

| Installation | Individual pieces, grout lines common | Fewer joints, seamless appearance |

| Applications | Flooring, walls, backsplashes | Countertops, large surfaces, walls, flooring |

| Durability | Highly durable and resistant to wear | Extremely durable, suitable for heavy use |

| Cost | More affordable per unit | Higher cost due to size and handling |

| Maintenance | Requires grout cleaning | Minimal grout, easier to clean |

| Design Options | Varied patterns and finishes | Continuous patterns, large-scale visuals |

Introduction to Porcelain Tiles and Porcelain Slabs

Porcelain tiles are small, thin pieces made from a blend of fine clay and minerals, ideal for flooring and wall applications due to their durability and water resistance. Porcelain slabs are larger, continuous surfaces crafted from similar materials, providing seamless coverage for countertops and expansive surfaces. Both options offer high density and low porosity, ensuring long-lasting performance in residential and commercial spaces.

Key Differences Between Porcelain Tiles and Porcelain Slabs

Porcelain tiles are typically smaller, modular units ranging from 12x12 to 24x48 inches, ideal for detailed designs and easier installation in residential or commercial spaces. Porcelain slabs, much larger at sizes like 5x10 feet or more, provide expansive, seamless surfaces suited for countertops, large flooring areas, or wall cladding, minimizing grout lines for a sleek aesthetic. The thickness also varies, with slabs generally thicker and heavier, offering superior durability and resistance to cracking compared to thinner porcelain tiles.

Composition and Manufacturing Process

Porcelain tile and porcelain slab share a high-density composition primarily made of kaolin, feldspar, and quartz, ensuring durability and water resistance. Tiles are produced through a pressing and firing process at temperatures above 1200degC, resulting in smaller, standardized pieces ideal for flooring and wall applications. In contrast, porcelain slabs undergo a similar composition but are manufactured in larger, continuous presses, allowing for expansive, seamless surfaces favored in countertops and large-format installations.

Size and Thickness Comparison

Porcelain tiles typically measure between 12x12 inches and 24x24 inches with thickness ranging from 8 to 10 millimeters, making them suitable for various flooring and wall applications. Porcelain slabs offer much larger dimensions, often exceeding 5 feet by 10 feet, and have greater thickness options, usually between 12 to 20 millimeters, providing enhanced durability for countertops and expansive surfaces. The size and thickness differences impact installation techniques, structural support requirements, and design flexibility in architectural projects.

Design Versatility and Aesthetic Appeal

Porcelain tiles offer design versatility with a wide range of sizes, patterns, and finishes ideal for intricate layouts and smaller spaces, enhancing aesthetic appeal through customizable grout options. Porcelain slabs provide a seamless, large-format surface that creates a sleek, modern look, minimizing grout lines for a clean, continuous aesthetic ideal for countertops and expansive flooring. Both options deliver durability and water resistance, but slabs excel in delivering a bold, luxurious visual impact with fewer interruptions in the design flow.

Installation Methods and Challenges

Porcelain tiles are typically installed using thin-set mortar with spacers to ensure uniform grout lines, offering straightforward handling and flexibility in layout, while porcelain slabs require large-format installation techniques, including specialized lifting equipment and minimal grout joints to accommodate their size and weight. The challenges of installing porcelain slabs include the risk of cracking during transport and placement, as well as the need for precise subfloor preparation to support the slab's weight evenly. Porcelain tile installation is generally more forgiving and accessible for DIY projects, whereas porcelain slabs demand professional expertise and careful planning to prevent installation mishaps.

Durability and Performance Factors

Porcelain slabs offer enhanced durability compared to standard porcelain tiles due to their larger size and reduced grout lines, which decreases the risk of cracking and water infiltration. The uniform density and low porosity of porcelain slabs ensure superior resistance to stains, scratches, and wear in high-traffic areas. Both porcelain tiles and slabs exhibit excellent performance factors, but slabs provide a more continuous surface ideal for seamless installations and increased structural strength.

Maintenance and Cleaning Requirements

Porcelain tiles require regular sweeping and mopping with mild detergent to prevent dirt buildup and maintain their durability, while porcelain slabs, due to their larger size and fewer grout lines, generally need less frequent cleaning and are easier to wipe down. Both porcelain tiles and slabs resist stains and moisture effectively, but slabs minimize grout maintenance, reducing the risk of mold and mildew compared to tiles. Proper sealing is recommended for both surfaces to enhance stain resistance and prolong their lifespan.

Cost Comparison: Tiles vs Slabs

Porcelain tiles generally cost less per square foot compared to porcelain slabs due to their smaller size and mass production, making them a budget-friendly option for many projects. Porcelain slabs, while more expensive, offer a sleek, seamless appearance and require less grout, which can reduce installation labor costs over time. The higher initial investment for slabs often balances out with their durability and design versatility, especially in high-end applications.

Best Applications for Porcelain Tiles and Slabs

Porcelain tiles are ideal for flooring, backsplashes, and walls in residential and commercial settings due to their durability, moisture resistance, and ease of installation. Porcelain slabs, with their larger dimensions and minimal grout lines, excel in countertop surfaces, large wall panels, and seamless flooring for modern, high-end design applications. Both porcelain tiles and slabs offer exceptional stain resistance and low porosity, making them suitable for high-traffic areas and wet environments such as bathrooms and kitchens.

Porcelain Tile vs Porcelain Slab Infographic

materialdif.com

materialdif.com