Porcelain clay and kaolin clay are both essential materials in ceramics, but porcelain clay combines kaolin with other clays and minerals to enhance plasticity and firing properties. Kaolin clay is a pure, white clay primarily composed of kaolinite, known for its high refractory quality and whiteness, which makes it ideal for fine porcelain production. Porcelain clay's mixture allows for a smoother texture and translucency after firing, while kaolin clay offers strength and a high melting point critical for durability.

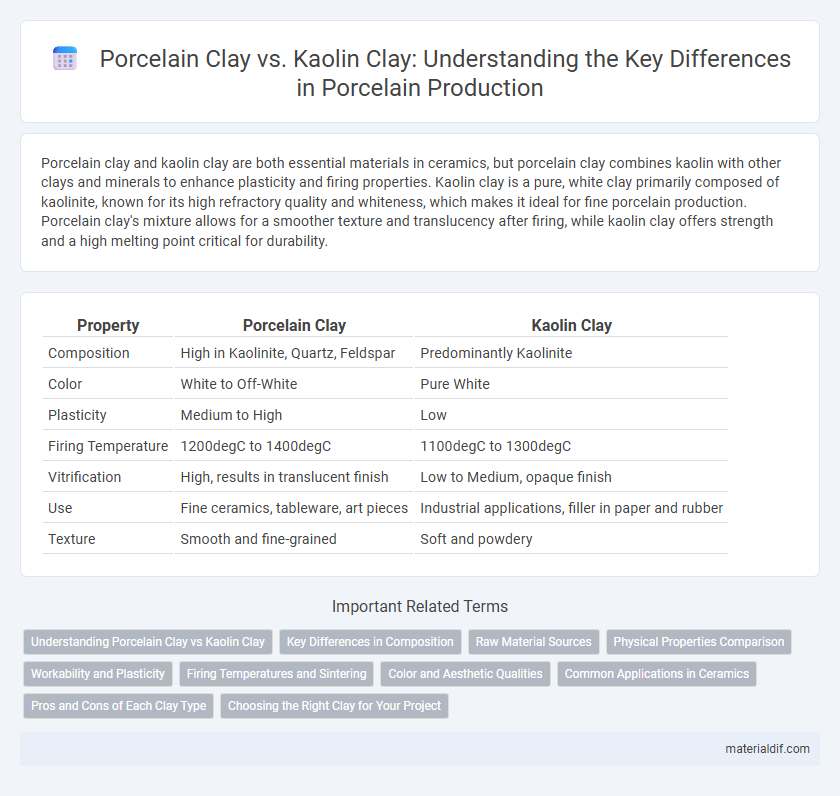

Table of Comparison

| Property | Porcelain Clay | Kaolin Clay |

|---|---|---|

| Composition | High in Kaolinite, Quartz, Feldspar | Predominantly Kaolinite |

| Color | White to Off-White | Pure White |

| Plasticity | Medium to High | Low |

| Firing Temperature | 1200degC to 1400degC | 1100degC to 1300degC |

| Vitrification | High, results in translucent finish | Low to Medium, opaque finish |

| Use | Fine ceramics, tableware, art pieces | Industrial applications, filler in paper and rubber |

| Texture | Smooth and fine-grained | Soft and powdery |

Understanding Porcelain Clay vs Kaolin Clay

Porcelain clay and kaolin clay are both key materials in ceramics, with porcelain clay being a refined mixture that includes kaolin, feldspar, and quartz, providing the translucency and strength distinctive to porcelain. Kaolin clay, also known as china clay, is a primary ingredient in porcelain but is more plastic and less vitrified on its own, resulting in a softer, less durable ceramic when fired. Understanding these differences is crucial for potters aiming to achieve specific aesthetic and functional qualities in porcelain production.

Key Differences in Composition

Porcelain clay primarily contains a higher percentage of kaolin, feldspar, and silica, providing its characteristic translucency and strength after firing. Kaolin clay consists mostly of pure kaolinite mineral, which contributes to its white color and plasticity, but it lacks the fluxing agents found in porcelain clay. The key difference lies in porcelain's balanced composition that melts at high temperatures to create a vitrified, durable surface, whereas kaolin clay remains more porous and less glass-like post-firing.

Raw Material Sources

Porcelain clay primarily derives from kaolin, a pure white clay mineral sourced from decomposed feldspar-rich rocks, notably granite. Kaolin clay deposits are abundant in regions like Georgia in the United States, Jingdezhen in China, and Cornwall in the United Kingdom, providing the critical raw material for high-quality porcelain production. While porcelain clay includes kaolin, it often contains additional minerals such as feldspar and quartz, which affect its plasticity and firing properties.

Physical Properties Comparison

Porcelain clay exhibits a finer particle size and higher plasticity compared to kaolin clay, which is coarser and less plastic. Porcelain clay typically has a lower firing shrinkage rate and achieves greater translucency and whiteness post-firing due to its mineral composition and impurities. In contrast, kaolin clay, rich in kaolinite, provides excellent whiteness and strength but is more refractory and less vitrifiable than porcelain clay.

Workability and Plasticity

Porcelain clay offers superior plasticity compared to kaolin clay, allowing for easier shaping and manipulation during the forming process. Kaolin clay, while less plastic, provides greater strength and whiteness after firing but requires blending with other clays to improve workability. The choice between porcelain and kaolin clay depends on balancing the need for smooth, workable texture with the desired final strength and translucency of the ceramic piece.

Firing Temperatures and Sintering

Porcelain clay typically fires at higher temperatures, around 1200degC to 1400degC, promoting a dense, vitrified body through intense sintering, whereas kaolin clay generally matures at lower temperatures near 1100degC to 1300degC. The sintering process in porcelain clay results in greater translucency and strength due to its high-firing range and fine particle size. Kaolin clay's lower firing temperature yields a more porous and less vitrified finish, making it less durable than porcelain.

Color and Aesthetic Qualities

Porcelain clay typically exhibits a pure white color that enhances its smooth, translucent finish, making it ideal for fine china and decorative items. Kaolin clay, a key component of porcelain, is naturally white but can vary slightly in shade depending on impurities, affecting final aesthetics by introducing subtle tones. The combination of these clays balances whiteness and translucency, contributing to porcelain's renowned elegance and refined visual appeal.

Common Applications in Ceramics

Porcelain clay and kaolin clay are fundamental materials in ceramics, with porcelain clay prized for its translucency and strength, making it ideal for fine dinnerware and decorative objects. Kaolin clay, a primary ingredient in porcelain, excels in refractory applications and is widely used for sanitary ware, tiles, and electrical insulators due to its purity and high firing temperature resistance. Both clays contribute essential properties in ceramics manufacturing, balancing plasticity, whiteness, and durability for diverse industrial and artistic uses.

Pros and Cons of Each Clay Type

Porcelain clay offers high plasticity and a smooth texture, producing strong, translucent finished pieces, but it requires precise firing temperatures and can be difficult for beginners to handle. Kaolin clay, a primary ingredient in porcelain, provides excellent whiteness and thermal resistance, making it ideal for detailed work, though its low plasticity demands blending with other clays to improve workability. Choosing between porcelain clay and kaolin clay depends on the desired finish, firing requirements, and the skill level of the ceramic artist.

Choosing the Right Clay for Your Project

Porcelain clay and kaolin clay each offer distinct advantages for ceramics, with porcelain clay known for its fine, translucent quality and high firing temperature ideal for delicate, high-strength pieces. Kaolin clay, a primary ingredient in porcelain, is prized for its purity, whiteness, and plasticity, making it suitable for versatility in both artistic and industrial applications. Selecting the right clay depends on your project's need for translucency, strength, and firing temperature, where porcelain clay suits fine-art ceramics and kaolin clay excels in functional wares and combined clay bodies.

Porcelain Clay vs Kaolin Clay Infographic

materialdif.com

materialdif.com