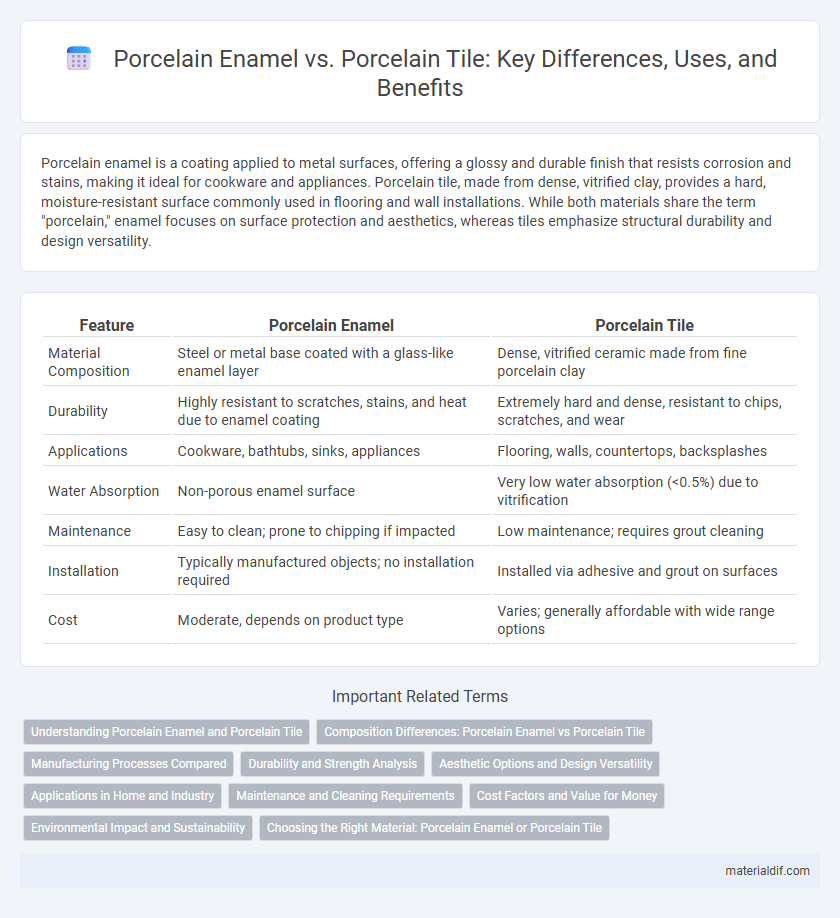

Porcelain enamel is a coating applied to metal surfaces, offering a glossy and durable finish that resists corrosion and stains, making it ideal for cookware and appliances. Porcelain tile, made from dense, vitrified clay, provides a hard, moisture-resistant surface commonly used in flooring and wall installations. While both materials share the term "porcelain," enamel focuses on surface protection and aesthetics, whereas tiles emphasize structural durability and design versatility.

Table of Comparison

| Feature | Porcelain Enamel | Porcelain Tile |

|---|---|---|

| Material Composition | Steel or metal base coated with a glass-like enamel layer | Dense, vitrified ceramic made from fine porcelain clay |

| Durability | Highly resistant to scratches, stains, and heat due to enamel coating | Extremely hard and dense, resistant to chips, scratches, and wear |

| Applications | Cookware, bathtubs, sinks, appliances | Flooring, walls, countertops, backsplashes |

| Water Absorption | Non-porous enamel surface | Very low water absorption (<0.5%) due to vitrification |

| Maintenance | Easy to clean; prone to chipping if impacted | Low maintenance; requires grout cleaning |

| Installation | Typically manufactured objects; no installation required | Installed via adhesive and grout on surfaces |

| Cost | Moderate, depends on product type | Varies; generally affordable with wide range options |

Understanding Porcelain Enamel and Porcelain Tile

Porcelain enamel is a glassy, fused coating applied to metal surfaces, providing durability, corrosion resistance, and a smooth, glossy finish ideal for cookware and appliances. Porcelain tile is a dense, low-porosity ceramic product made from refined clay fired at high temperatures, renowned for its hardness, water resistance, and suitability for flooring and wall applications. Understanding the distinct composition and applications highlights porcelain enamel's role as a protective coating, while porcelain tile serves as a structural, decorative surface material.

Composition Differences: Porcelain Enamel vs Porcelain Tile

Porcelain enamel consists of a glassy coating fused onto metal, typically steel or cast iron, providing a smooth, durable, and corrosion-resistant surface ideal for cookware and appliances. Porcelain tile is made from a denser, refined clay mixture fired at higher temperatures, resulting in a hard, dense, and water-resistant ceramic primarily used for flooring and wall applications. The key composition difference lies in porcelain enamel's vitreous enamel layer on metal substrates versus porcelain tile's solid ceramic body.

Manufacturing Processes Compared

Porcelain enamel is created by fusing powdered glass to a metal substrate through high-temperature firing, resulting in a durable, smooth, and glossy coating often used on cookware and appliances. Porcelain tile manufacturing involves shaping refined clay and minerals into slabs, which are then fired at extremely high temperatures to achieve hardness and low porosity. While porcelain enamel combines glass and metal for a protective surface, porcelain tile relies on vitrification of ceramic materials for structural strength and water resistance.

Durability and Strength Analysis

Porcelain enamel offers superior durability due to its glass-like coating fused to metal, making it resistant to scratches, chipping, and corrosion. Porcelain tile, while also highly durable, is a dense ceramic material designed to withstand heavy foot traffic and impact but can be more prone to cracking under extreme pressure. Both materials excel in strength, but porcelain enamel outperforms in resisting surface damage, whereas porcelain tile provides robust structural integrity for flooring applications.

Aesthetic Options and Design Versatility

Porcelain enamel offers a sleek, glossy finish ideal for appliances and cookware, providing limited color variations but excellent durability and smooth surface appeal, while porcelain tile excels in design versatility with a broad spectrum of colors, textures, and patterns suitable for floors and walls. Porcelain tiles can mimic natural materials like stone and wood, allowing for customizable layouts and artistic installations that enhance aesthetic options across interior spaces. The choice between porcelain enamel and porcelain tile should consider the intended application's visual impact and design flexibility requirements.

Applications in Home and Industry

Porcelain enamel, a durable coating applied to metals, is extensively used in kitchen appliances, cookware, and industrial equipment for its resistance to corrosion and heat. Porcelain tiles, composed of refined clay fired at high temperatures, dominate flooring and wall surfaces in residential and commercial buildings due to their strength, water resistance, and aesthetic versatility. Both materials serve distinct roles: porcelain enamel enhances metal durability in manufacturing and household items, while porcelain tile provides a long-lasting, decorative solution for architectural finishes.

Maintenance and Cleaning Requirements

Porcelain enamel surfaces require regular cleaning with non-abrasive cleaners to prevent chipping and maintain their glossy finish, while porcelain tiles demand less frequent maintenance due to their durable, glazed surfaces that resist staining and scratches. Porcelain tiles benefit from easy grout cleaning and occasional sealing to prevent mold and mildew buildup, whereas porcelain enamel is more susceptible to wear and may need touch-ups over time. Overall, porcelain tiles offer a lower-maintenance and longer-lasting solution compared to porcelain enamel for high-traffic or moisture-prone areas.

Cost Factors and Value for Money

Porcelain enamel typically incurs lower initial costs due to cheaper base materials and simpler manufacturing compared to porcelain tile, which requires high-quality clay and precise firing processes. Despite the higher upfront expense, porcelain tile offers superior durability, resistance to wear, and aesthetic versatility, providing greater long-term value for money in both residential and commercial applications. Cost factors also include installation complexity, where porcelain tile demands skilled labor and longer installation time, influencing overall project budget significantly.

Environmental Impact and Sustainability

Porcelain enamel and porcelain tile differ significantly in their environmental impact and sustainability; porcelain tile is primarily made from natural clay and minerals, offering high durability and recyclability, which reduces waste and resource consumption. Porcelain enamel, created by fusing powdered glass to metal, often requires more energy-intensive processes and uses non-renewable metal substrates, leading to a larger carbon footprint. Choosing porcelain tile supports sustainable construction through lower embodied energy and greater potential for reuse and recycling compared to porcelain enamel.

Choosing the Right Material: Porcelain Enamel or Porcelain Tile

Porcelain enamel offers a durable, glass-like coating fused to metal, ideal for cookware and appliances requiring heat resistance and easy cleaning, while porcelain tile provides a dense, vitrified ceramic surface favored for flooring and wall applications due to its strength and aesthetic versatility. Selecting between porcelain enamel and porcelain tile depends on the intended use, with enamel suited for functional, protective surfaces and tile chosen for architectural and decorative purposes. Consider factors such as durability, installation requirements, and exposure to heat or moisture when deciding the appropriate material for your project.

Porcelain Enamel vs Porcelain Tile Infographic

materialdif.com

materialdif.com