Porcelain enamel features a glassy coating fused onto metal, providing a durable, non-porous surface resistant to scratches and stains, making it ideal for pet bowls. Porcelain ceramic, crafted from clay and fired at high temperatures, offers a solid, dense structure but can be more prone to chipping and absorbing moisture over time. Choosing between porcelain enamel and porcelain ceramic for pet products depends on the need for durability versus aesthetic finish and care requirements.

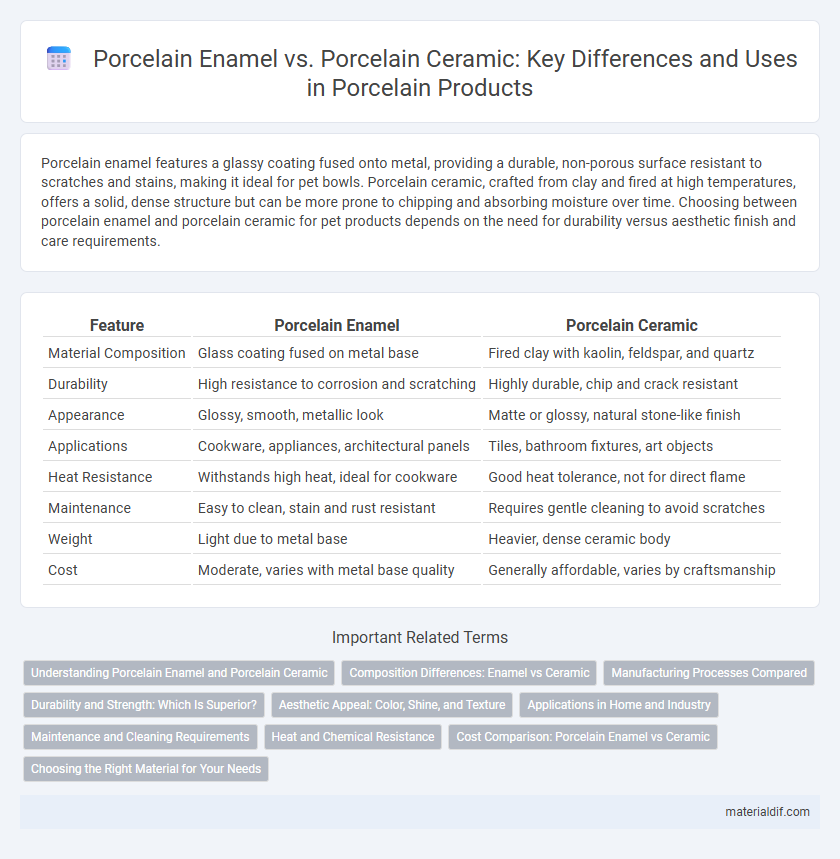

Table of Comparison

| Feature | Porcelain Enamel | Porcelain Ceramic |

|---|---|---|

| Material Composition | Glass coating fused on metal base | Fired clay with kaolin, feldspar, and quartz |

| Durability | High resistance to corrosion and scratching | Highly durable, chip and crack resistant |

| Appearance | Glossy, smooth, metallic look | Matte or glossy, natural stone-like finish |

| Applications | Cookware, appliances, architectural panels | Tiles, bathroom fixtures, art objects |

| Heat Resistance | Withstands high heat, ideal for cookware | Good heat tolerance, not for direct flame |

| Maintenance | Easy to clean, stain and rust resistant | Requires gentle cleaning to avoid scratches |

| Weight | Light due to metal base | Heavier, dense ceramic body |

| Cost | Moderate, varies with metal base quality | Generally affordable, varies by craftsmanship |

Understanding Porcelain Enamel and Porcelain Ceramic

Porcelain enamel is a durable coating made by fusing powdered glass to a metal substrate at high temperatures, creating a smooth, glossy surface resistant to corrosion and heat. Porcelain ceramic, on the other hand, is a dense, vitrified material composed mainly of kaolin clay, feldspar, and quartz, known for its strength, translucency, and fine texture. Understanding the distinction highlights that porcelain enamel functions as a protective and decorative layer, while porcelain ceramic constitutes a structural, standalone material used in tableware, tiles, and sanitary ware.

Composition Differences: Enamel vs Ceramic

Porcelain enamel is a glass-like coating fused onto metal surfaces, composed mainly of silica, feldspar, and borax, creating a durable, non-porous, and glossy finish. Porcelain ceramic consists primarily of kaolin, quartz, and feldspar, forming a dense, vitrified body that is more brittle but offers superior heat resistance and translucency. The key composition difference lies in porcelain enamel being a fused glass coating on metal, whereas porcelain ceramic is a solid, fired clay-based material.

Manufacturing Processes Compared

Porcelain enamel is created by fusing powdered glass to a metal substrate through high-temperature firing, resulting in a smooth, durable surface resistant to corrosion and heat. Porcelain ceramic is made by shaping and firing refined clay and minerals at even higher temperatures to achieve a dense, vitrified structure with excellent mechanical strength and low porosity. The manufacturing process of porcelain enamel emphasizes coating and bonding techniques, while porcelain ceramic production focuses on material compaction and sintering to form a solid, homogenous body.

Durability and Strength: Which Is Superior?

Porcelain enamel, a coating applied to metal surfaces, offers exceptional durability and resistance to chipping, scratching, and corrosion, making it ideal for cookware and industrial applications. Porcelain ceramic, composed of finely ground kaolin and fired at high temperatures, excels in hardness and strength, delivering superior fracture resistance and longevity in delicate uses like fine china and tiles. For durability and strength, porcelain ceramic generally surpasses porcelain enamel due to its dense, vitrified structure that withstands mechanical stress more effectively.

Aesthetic Appeal: Color, Shine, and Texture

Porcelain enamel offers a vibrant, glossy finish with a smooth, glass-like texture that enhances color intensity and shine, making it ideal for decorative surfaces. Porcelain ceramic features a more matte or satin texture with subtle color variations and a naturally elegant, tactile feel. The contrast in surface finishes influences aesthetic appeal, where enamel excels in boldness and brightness, while ceramic provides understated sophistication.

Applications in Home and Industry

Porcelain enamel is commonly used in industrial applications such as cookware, appliances, and architectural panels due to its durable, glass-like coating that resists corrosion and high temperatures. Porcelain ceramic, typically employed in home settings, is favored for decorative items, dinnerware, and bathroom fixtures because of its refined texture and high mechanical strength. Both materials excel in durability and aesthetic appeal, but porcelain enamel's heat resistance and chemical inertness make it ideal for heavy-duty industrial uses.

Maintenance and Cleaning Requirements

Porcelain enamel features a glassy coating that provides a non-porous, smooth surface, making it highly resistant to stains and easy to clean with mild detergents and soft cloths. Porcelain ceramic, while durable, has a more porous texture that can absorb dirt and requires regular sealing to maintain its resistance to staining and moisture. Maintenance for porcelain enamel typically involves minimal effort compared to porcelain ceramic, which demands more frequent cleaning and sealing to preserve its appearance and longevity.

Heat and Chemical Resistance

Porcelain enamel features a glassy coating fused to a metal substrate, providing excellent heat resistance and superior protection against chemical corrosion, making it ideal for cookware and industrial applications. Porcelain ceramic, composed primarily of kaolin, feldspar, and quartz, offers high heat resistance but is more brittle and less resistant to chemical damage compared to porcelain enamel. Both materials withstand high temperatures, but porcelain enamel's durable surface enhances longevity and resistance in harsh chemical environments.

Cost Comparison: Porcelain Enamel vs Ceramic

Porcelain enamel typically costs more upfront than porcelain ceramic due to the specialized metal substrate and coating process, which increases durability and resistance to corrosion. Porcelain ceramic, being a denser and less expensive material, offers a more budget-friendly option for applications like tiles and dinnerware. Long-term maintenance expenses generally favor porcelain enamel because its protective coating reduces the need for frequent replacements or repairs.

Choosing the Right Material for Your Needs

Porcelain enamel offers a durable, glass-like coating fused to metal, providing superior resistance to rust, scratches, and high temperatures, making it ideal for cookware and appliances requiring longevity and easy cleaning. Porcelain ceramic, a dense and non-porous material fired at high temperatures, excels in aesthetic appeal and heat retention, commonly used for tiles, dinnerware, and decorative items. Selecting between porcelain enamel and porcelain ceramic depends on prioritizing either durability and protection for functional objects or visual elegance and thermal properties for decorative and practical uses.

Porcelain Enamel vs Porcelain Ceramic Infographic

materialdif.com

materialdif.com