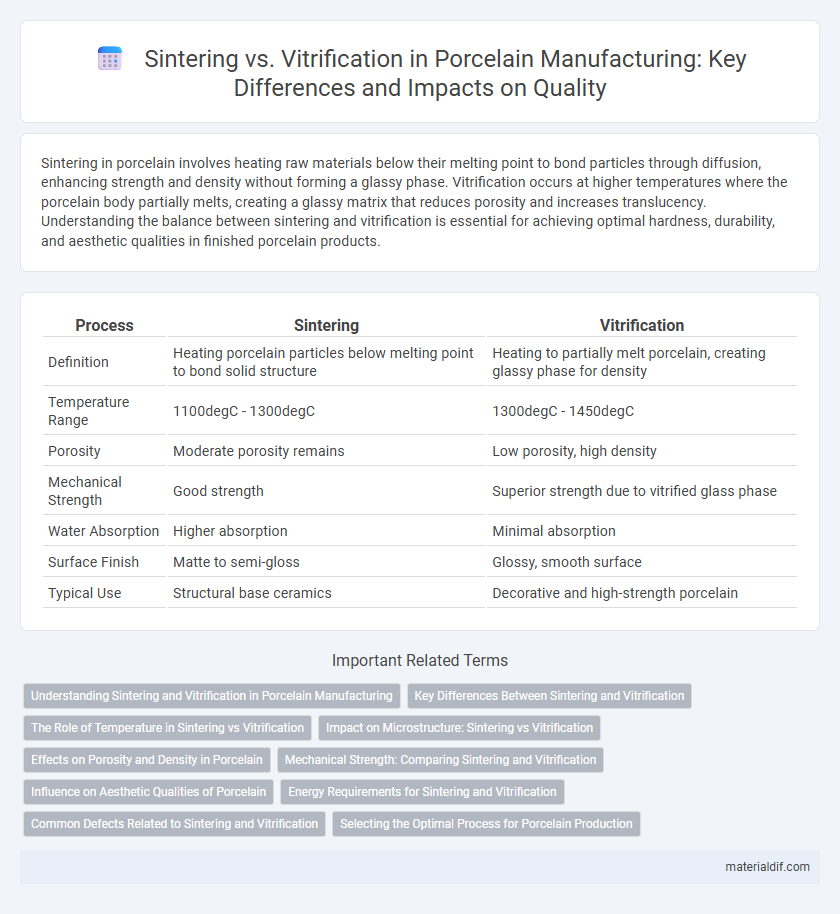

Sintering in porcelain involves heating raw materials below their melting point to bond particles through diffusion, enhancing strength and density without forming a glassy phase. Vitrification occurs at higher temperatures where the porcelain body partially melts, creating a glassy matrix that reduces porosity and increases translucency. Understanding the balance between sintering and vitrification is essential for achieving optimal hardness, durability, and aesthetic qualities in finished porcelain products.

Table of Comparison

| Process | Sintering | Vitrification |

|---|---|---|

| Definition | Heating porcelain particles below melting point to bond solid structure | Heating to partially melt porcelain, creating glassy phase for density |

| Temperature Range | 1100degC - 1300degC | 1300degC - 1450degC |

| Porosity | Moderate porosity remains | Low porosity, high density |

| Mechanical Strength | Good strength | Superior strength due to vitrified glass phase |

| Water Absorption | Higher absorption | Minimal absorption |

| Surface Finish | Matte to semi-gloss | Glossy, smooth surface |

| Typical Use | Structural base ceramics | Decorative and high-strength porcelain |

Understanding Sintering and Vitrification in Porcelain Manufacturing

Sintering in porcelain manufacturing involves heating powdered materials below their melting point to bond particles, enhancing strength and density. Vitrification refers to the transformation of porcelain into a glass-like, non-porous state through higher temperature firing, improving translucency and durability. Understanding these processes is critical for controlling porcelain's final mechanical properties and aesthetic qualities.

Key Differences Between Sintering and Vitrification

Sintering in porcelain involves heating powdered materials below their melting point to fuse particles together, enhancing mechanical strength without full liquefaction. Vitrification occurs at higher temperatures, transforming the porcelain body into a glassy, non-porous state that imparts translucency, durability, and water resistance. Key differences lie in sintering's solid-state bonding versus vitrification's partial melting that creates a dense, impermeable structure essential for high-quality porcelain.

The Role of Temperature in Sintering vs Vitrification

Temperature plays a critical role in both sintering and vitrification during the porcelain production process, with sintering typically occurring at lower temperatures around 1100degC to 1300degC to bond fine particles and enhance mechanical strength without melting. Vitrification requires higher temperatures, usually above 1300degC, where the porcelain body partially melts, forming a glassy phase that increases density, translucency, and water resistance. Controlling the precise temperature during firing ensures the optimal balance between sintered particle bonding and vitrified glass formation for superior porcelain quality.

Impact on Microstructure: Sintering vs Vitrification

Sintering in porcelain processing causes particle bonding and neck growth, leading to a porous microstructure with partially fused grains. Vitrification, by contrast, results in a dense, glassy matrix that fills pores and significantly reduces porosity, enhancing mechanical strength and translucency. The microstructural shift from sintered crystalline frameworks to vitrified amorphous glass phases directly influences the durability and aesthetic qualities of finished porcelain products.

Effects on Porosity and Density in Porcelain

Sintering in porcelain reduces porosity by partially fusing particles, resulting in moderate density improvement, while vitrification significantly lowers porosity through the formation of a glassy phase that fills pores and increases overall density. Porcelain subjected to vitrification exhibits enhanced mechanical strength and translucency due to its near-zero porosity and highly compact microstructure. Density measurements confirm that vitrified porcelain attains values closer to theoretical density compared to sintered porcelain, highlighting the critical role of vitrification in achieving high-performance ceramic materials.

Mechanical Strength: Comparing Sintering and Vitrification

Sintering in porcelain involves heating particles below melting point to bond material, resulting in moderate mechanical strength due to partial densification. Vitrification leads to a glassy phase formation through higher temperature heating, significantly increasing porcelain's mechanical strength and durability by reducing porosity. Porcelain products with vitrification exhibit superior hardness, fracture toughness, and resistance to wear compared to those relying solely on sintering.

Influence on Aesthetic Qualities of Porcelain

Sintering influences the density and translucency of porcelain by promoting particle bonding without complete melting, resulting in a more matte and textured surface. Vitrification enhances the porcelain's glossiness and smoothness through partial melting, creating a glassy phase that significantly improves translucency and color depth. The balance between sintering and vitrification determines the final aesthetic quality, including brightness, clarity, and surface finish of the porcelain piece.

Energy Requirements for Sintering and Vitrification

Sintering in porcelain production requires lower temperatures, typically between 1100degC and 1300degC, resulting in reduced energy consumption compared to vitrification, which occurs at higher temperatures above 1300degC to achieve full glassy phase formation. The energy efficiency of sintering makes it suitable for preliminary densification, while vitrification demands substantial energy input to develop the porcelain's final strength and impermeability. Optimizing these thermal processes directly impacts production costs and environmental sustainability in porcelain manufacturing.

Common Defects Related to Sintering and Vitrification

Common defects related to sintering in porcelain include warping, bloating, and incomplete densification, which result from insufficient temperature or uneven heating. Vitrification defects often involve excessive glass phase formation, leading to excessive translucency, crazing, or reduced mechanical strength. Controlling temperature profiles and raw material composition is critical to minimize defects and ensure optimal porcelain integrity.

Selecting the Optimal Process for Porcelain Production

Sintering in porcelain production involves heating powdered materials below their melting points to bond particles through diffusion, resulting in enhanced mechanical strength and controlled porosity. Vitrification entails heating porcelain to a temperature where partial melting occurs, creating a glassy phase that increases translucency and impermeability. Selecting the optimal process depends on desired properties: sintering suits applications needing structural integrity with some porosity, while vitrification favors aesthetic quality and water resistance in fine porcelain products.

Sintering vs Vitrification (in porcelain process) Infographic

materialdif.com

materialdif.com