Porcelain exhibits higher strength and durability compared to traditional ceramics due to its denser composition and vitrification process, which reduces porosity and enhances resistance to chipping and cracking. Ceramic, while strong, is generally more porous and less dense, making it more susceptible to wear and breakage under heavy use. The superior hardness and resilience of porcelain make it ideal for applications requiring long-lasting performance and aesthetic appeal.

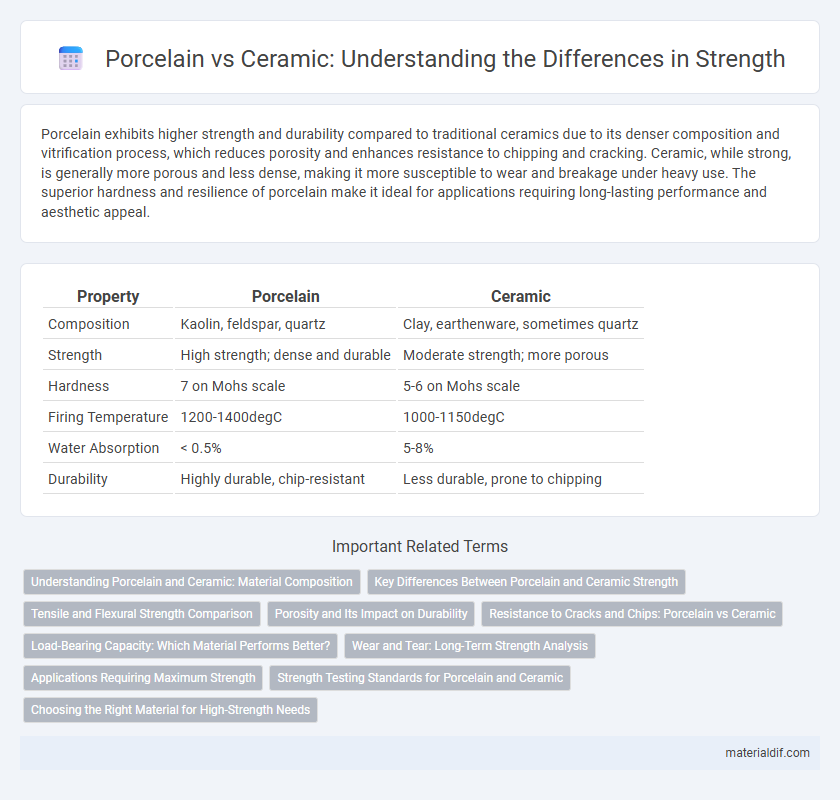

Table of Comparison

| Property | Porcelain | Ceramic |

|---|---|---|

| Composition | Kaolin, feldspar, quartz | Clay, earthenware, sometimes quartz |

| Strength | High strength; dense and durable | Moderate strength; more porous |

| Hardness | 7 on Mohs scale | 5-6 on Mohs scale |

| Firing Temperature | 1200-1400degC | 1000-1150degC |

| Water Absorption | < 0.5% | 5-8% |

| Durability | Highly durable, chip-resistant | Less durable, prone to chipping |

Understanding Porcelain and Ceramic: Material Composition

Porcelain exhibits higher strength and durability compared to general ceramics due to its unique composition of kaolin, feldspar, and quartz fired at higher temperatures. This mineral blend creates a dense, vitrified structure that enhances resistance to chipping, scratching, and thermal shock. In contrast, traditional ceramics often have a more porous composition, leading to lower mechanical strength and greater susceptibility to damage.

Key Differences Between Porcelain and Ceramic Strength

Porcelain exhibits higher strength and durability compared to ceramic due to its denser composition and finer clay, which results in greater resistance to chipping and cracking. Porcelain is typically fired at higher temperatures, around 1,200 to 1,400 degrees Celsius, enhancing its hardness and making it less porous than ceramic, which is fired at lower temperatures. These properties make porcelain ideal for high-traffic areas and heavy-use applications, whereas ceramic is more suitable for decorative or light-use purposes.

Tensile and Flexural Strength Comparison

Porcelain exhibits higher tensile strength than many traditional ceramics due to its dense microstructure and vitrification process, resulting in enhanced resistance to cracking under tension. Flexural strength tests reveal that porcelain typically outperforms general ceramics, with values often ranging from 40 to 70 MPa compared to 30 to 50 MPa for standard ceramics. These strength characteristics make porcelain a preferred choice for applications requiring durability and mechanical reliability under flexural stress.

Porosity and Its Impact on Durability

Porcelain exhibits lower porosity compared to ceramic, resulting in enhanced strength and durability due to fewer microscopic voids that can weaken the material. Reduced porosity in porcelain limits water absorption, making it more resistant to cracking and wear over time. This intrinsic property contributes to porcelain's superior performance in high-traffic and demanding environments compared to traditional ceramic.

Resistance to Cracks and Chips: Porcelain vs Ceramic

Porcelain exhibits greater resistance to cracks and chips compared to traditional ceramic due to its denser and finer particle composition, which enhances its durability under stress. The vitrification process in porcelain results in lower porosity, making it less susceptible to moisture absorption and weakening over time. These properties enable porcelain to maintain structural integrity in high-traffic areas, outperforming standard ceramics in crack and chip resistance.

Load-Bearing Capacity: Which Material Performs Better?

Porcelain exhibits superior load-bearing capacity compared to traditional ceramics due to its denser microstructure and higher firing temperatures, resulting in greater mechanical strength and resistance to fracture. This enhanced durability makes porcelain ideal for applications requiring robust performance under stress, such as flooring and structural components. In contrast, conventional ceramics, while still strong, typically offer lower load-bearing capabilities due to increased porosity and brittleness.

Wear and Tear: Long-Term Strength Analysis

Porcelain exhibits superior wear resistance compared to traditional ceramics due to its dense, vitrified microstructure that minimizes porosity and surface degradation. Over long-term use, porcelain maintains structural integrity and resists chipping and abrasion, making it ideal for high-traffic or load-bearing applications. Ceramics, while durable, tend to suffer more from micro-cracking and surface wear caused by repeated mechanical stress and environmental exposure.

Applications Requiring Maximum Strength

Porcelain exhibits higher strength and durability compared to standard ceramics due to its denser microstructure and lower porosity, making it ideal for applications requiring maximum strength such as dental restorations and industrial insulators. Its superior resistance to mechanical wear and thermal shock ensures long-lasting performance in demanding environments. While ceramics are suitable for decorative or less mechanically intensive uses, porcelain's enhanced tensile strength and fracture toughness provide critical advantages in structural and functional components.

Strength Testing Standards for Porcelain and Ceramic

Porcelain exhibits higher strength compared to conventional ceramics due to its dense microstructure and vitrification process. Strength testing standards such as ASTM C373 for water absorption and ASTM C1161 for flexural strength provide critical metrics for evaluating both porcelain and ceramic materials. These standards ensure consistent measurement of mechanical properties, with porcelain typically demonstrating flexural strengths exceeding 40 MPa, while standard ceramics often fall below 35 MPa.

Choosing the Right Material for High-Strength Needs

Porcelain exhibits higher strength and durability compared to standard ceramics due to its vitrified, dense microstructure and lower porosity, making it ideal for applications requiring superior mechanical resistance. High-strength porcelain materials often achieve flexural strengths ranging from 50 to 70 MPa, significantly exceeding typical ceramic strength values, which usually fall between 20 to 40 MPa. Selecting porcelain for high-strength needs ensures enhanced fracture toughness and long-term performance in demanding environments like dental restorations, aerospace components, and industrial coatings.

Porcelain Strength vs Ceramic Strength Infographic

materialdif.com

materialdif.com