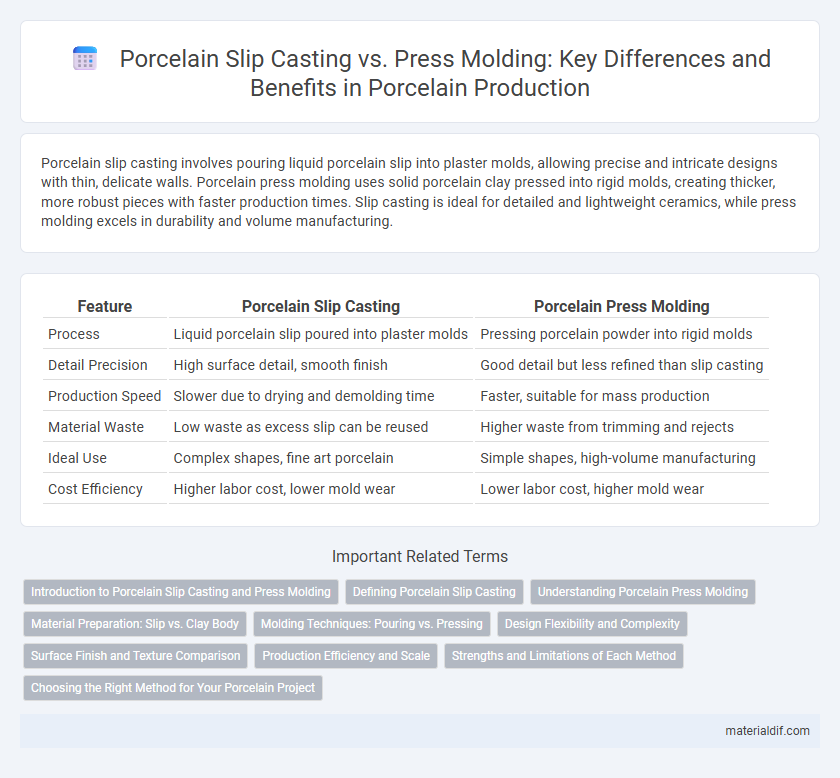

Porcelain slip casting involves pouring liquid porcelain slip into plaster molds, allowing precise and intricate designs with thin, delicate walls. Porcelain press molding uses solid porcelain clay pressed into rigid molds, creating thicker, more robust pieces with faster production times. Slip casting is ideal for detailed and lightweight ceramics, while press molding excels in durability and volume manufacturing.

Table of Comparison

| Feature | Porcelain Slip Casting | Porcelain Press Molding |

|---|---|---|

| Process | Liquid porcelain slip poured into plaster molds | Pressing porcelain powder into rigid molds |

| Detail Precision | High surface detail, smooth finish | Good detail but less refined than slip casting |

| Production Speed | Slower due to drying and demolding time | Faster, suitable for mass production |

| Material Waste | Low waste as excess slip can be reused | Higher waste from trimming and rejects |

| Ideal Use | Complex shapes, fine art porcelain | Simple shapes, high-volume manufacturing |

| Cost Efficiency | Higher labor cost, lower mold wear | Lower labor cost, higher mold wear |

Introduction to Porcelain Slip Casting and Press Molding

Porcelain slip casting involves pouring liquid clay slip into plaster molds where water absorption solidifies the clay, producing intricate and uniform shapes ideal for detailed porcelain items. Porcelain press molding uses a combination of dry or semi-dry porcelain clay pressed into steel or plaster molds under significant pressure, allowing for faster production of consistent thickness and denser porcelain pieces. Both methods are pivotal in ceramic manufacturing, with slip casting favored for complex designs and press molding optimized for high-volume, robust porcelain products.

Defining Porcelain Slip Casting

Porcelain slip casting involves pouring liquid clay slip into plaster molds, allowing the water to be absorbed, and forming a uniform, thin ceramic shell that can be easily removed and fired. This method enables intricate shapes and fine details in porcelain production, offering superior control over wall thickness and surface texture compared to press molding. Slip casting is particularly effective for creating complex porcelain items with consistent quality and minimal waste.

Understanding Porcelain Press Molding

Porcelain press molding involves using high-pressure hydraulic presses to shape fine porcelain powder mixed with a binder into precise, dense forms, offering superior surface finish and dimensional accuracy compared to slip casting. This method enables faster production cycles and reduces the likelihood of defects such as warping or shrinkage, making it ideal for complex or high-volume porcelain items. Unlike slip casting, which relies on liquid clay slip pouring into molds, press molding requires specially designed metal molds that withstand repeated high-pressure cycles.

Material Preparation: Slip vs. Clay Body

Porcelain slip casting uses a liquid slip, a fine suspension of porcelain clay particles mixed with water, ensuring precise flow into molds for detailed, thin-walled objects. Press molding relies on a plastic clay body, a denser, malleable form of porcelain clay prepared by kneading to achieve the right consistency for pressing into molds. The choice between slip and clay body in material preparation directly impacts the texture, porosity, and final strength of the porcelain piece.

Molding Techniques: Pouring vs. Pressing

Porcelain slip casting involves pouring liquid clay slip into a plaster mold, allowing the walls to form as moisture is absorbed, creating intricate shapes with fine details and thin walls. Porcelain press molding uses a dense clay body pressed into a flexible mold under pressure, producing uniform thickness and faster production suited for sturdier designs. Pouring emphasizes fluidity and delicate forms, while pressing focuses on efficiency and consistent thickness in manufacturing porcelain pieces.

Design Flexibility and Complexity

Porcelain slip casting enables high design flexibility and intricate detail by pouring liquid slip into molds, allowing for complex, hollow shapes and fine surface textures that are difficult to achieve with press molding. Porcelain press molding offers faster production and better consistency for simpler, solid forms but limits complexity due to the pressing process's constraints on intricate features. Choosing slip casting enhances artistic expression and detailed craftsmanship, while press molding prioritizes efficiency and uniformity in porcelain piece production.

Surface Finish and Texture Comparison

Porcelain slip casting produces a smooth, uniform surface finish due to the liquid clay filling detailed molds, capturing fine textures with high precision. Porcelain press molding yields a denser texture with sharper edges and more consistent thickness but may have minor surface imperfections from mold release agents. Slip casting is preferred for intricate, delicate designs requiring a refined finish, while press molding suits robust forms with defined texture patterns.

Production Efficiency and Scale

Porcelain slip casting offers higher production efficiency for complex shapes by utilizing liquid clay poured into molds, allowing uniform wall thickness and intricate details with minimal manual intervention. In contrast, porcelain press molding is better suited for larger scale production of simpler forms, providing faster cycle times and reduced material waste through mechanical pressing of clay into preformed molds. Manufacturers choose slip casting for artisanal precision and press molding for mass production when balancing speed, scalability, and design complexity.

Strengths and Limitations of Each Method

Porcelain slip casting offers precise detail and uniform wall thickness, making it ideal for intricate designs and high-quality finishes, but it requires longer drying times and careful control to prevent warping. Porcelain press molding excels in rapid production and consistent shapes, suitable for mass production with less material waste, though it may lack the fine detail achievable by slip casting and can result in thicker, less refined forms. Each method's strengths and limitations should be weighed according to the desired product complexity, production scale, and finish quality.

Choosing the Right Method for Your Porcelain Project

Porcelain slip casting offers precision and fine detail, ideal for complex or delicate shapes, using liquid porcelain slip poured into molds. Porcelain press molding provides faster production and consistency for simple, repetitive designs by pressing clay into rigid molds. Selecting the right method depends on project complexity, desired finish, and production volume, with slip casting preferred for artisanal quality and press molding suited for efficiency.

Porcelain Slip Casting vs Porcelain Press Molding Infographic

materialdif.com

materialdif.com