Porcelain vitrification involves firing at higher temperatures, typically between 1200degC and 1400degC, resulting in a dense, non-porous, and glass-like surface that enhances strength and translucency. Earthenware firing occurs at lower temperatures, around 1000degC to 1150degC, producing a more porous and less durable ceramic with a matte finish that requires glazing to hold liquids. The vitrification process distinguishes porcelain by its superior hardness, water resistance, and fine texture compared to the more porous and softer earthenware.

Table of Comparison

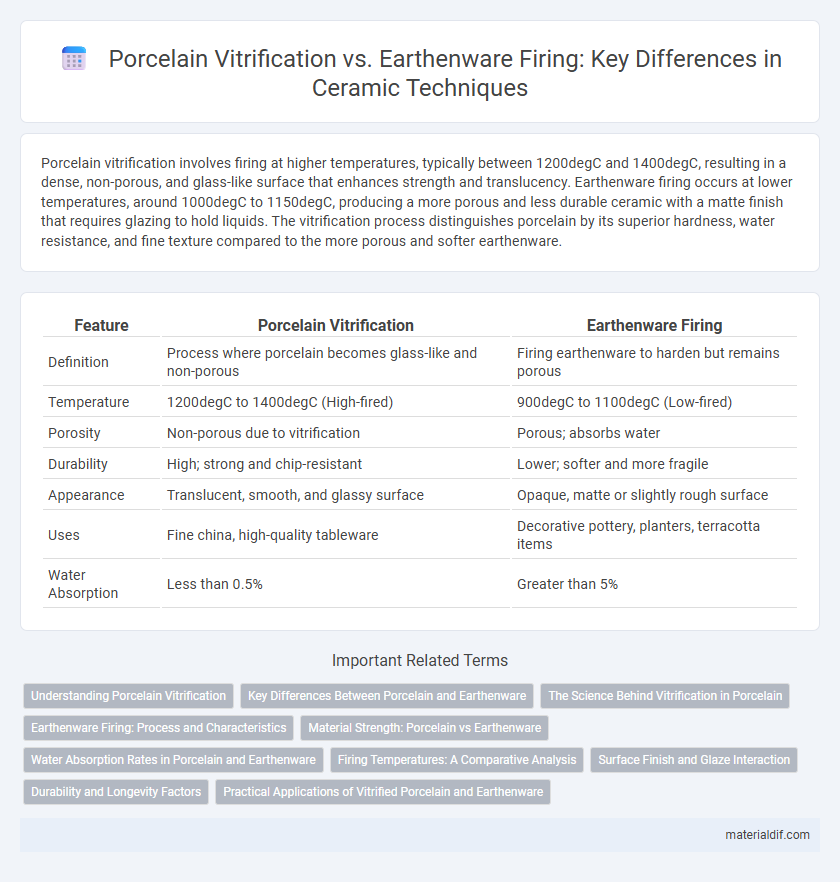

| Feature | Porcelain Vitrification | Earthenware Firing |

|---|---|---|

| Definition | Process where porcelain becomes glass-like and non-porous | Firing earthenware to harden but remains porous |

| Temperature | 1200degC to 1400degC (High-fired) | 900degC to 1100degC (Low-fired) |

| Porosity | Non-porous due to vitrification | Porous; absorbs water |

| Durability | High; strong and chip-resistant | Lower; softer and more fragile |

| Appearance | Translucent, smooth, and glassy surface | Opaque, matte or slightly rough surface |

| Uses | Fine china, high-quality tableware | Decorative pottery, planters, terracotta items |

| Water Absorption | Less than 0.5% | Greater than 5% |

Understanding Porcelain Vitrification

Porcelain vitrification occurs at higher temperatures, typically between 1200degC and 1400degC, resulting in a dense, glass-like, and non-porous surface that enhances strength and translucency. In contrast, earthenware firing occurs at lower temperatures, around 1000degC to 1150degC, producing a more porous and less durable product. Understanding porcelain vitrification is essential for achieving its characteristic impermeability and fine texture, distinguishing it from the more porous and less vitrified earthenware.

Key Differences Between Porcelain and Earthenware

Porcelain vitrification occurs at higher temperatures, typically between 1200-1400degC, resulting in a dense, non-porous, and glass-like surface, whereas earthenware firing happens at lower temperatures around 1000-1150degC, producing a more porous and less durable material. Porcelain's vitrified state enhances its strength, translucency, and resistance to moisture, unlike earthenware, which is more porous and often requires glazing to hold liquids. These firing differences impact the final product's texture, durability, and usage, with porcelain favored for fine china and artistic wares, while earthenware suits rustic pottery and everyday items.

The Science Behind Vitrification in Porcelain

Porcelain vitrification occurs when its silica and feldspar components melt at high temperatures, typically between 1200degC and 1400degC, forming a dense, glassy matrix that drastically reduces porosity and increases strength. Unlike earthenware firing, which occurs at lower temperatures (about 1000degC to 1150degC) and leaves the material more porous and less durable, porcelain's vitrification enhances translucency and resistance to water absorption. This scientific process transforms porcelain into a highly vitrified ceramic, prized for its hardness, whiteness, and ability to withstand thermal shock.

Earthenware Firing: Process and Characteristics

Earthenware firing involves heating clay at relatively low temperatures, typically between 1,000 to 1,150degC, resulting in a porous and less vitrified ceramic body compared to porcelain. This firing process allows earthenware to retain its porous structure, requiring glazing for waterproofing and increased durability. The lower firing temperature produces earthy tones and a softer texture, distinguishing earthenware from the highly vitrified, translucent qualities of porcelain.

Material Strength: Porcelain vs Earthenware

Porcelain achieves a higher vitrification level than earthenware, resulting in a denser, more non-porous material with significantly greater strength and durability. The firing temperature for porcelain typically ranges between 1,200degC and 1,400degC, promoting a glass-like, vitrified structure that enhances resistance to chipping and water absorption. In contrast, earthenware firing occurs at lower temperatures (around 1,000degC to 1,150degC), producing a more porous and softer material prone to fragility and less mechanical strength.

Water Absorption Rates in Porcelain and Earthenware

Porcelain vitrification creates a dense, glass-like structure with water absorption rates typically below 0.5%, making it highly impermeable compared to earthenware. Earthenware firing results in a more porous body with water absorption rates ranging from 5% to 15%, which significantly affects durability and moisture resistance. The low water absorption of vitrified porcelain enhances its suitability for functional and decorative uses requiring strength and minimal water penetration.

Firing Temperatures: A Comparative Analysis

Porcelain vitrification typically occurs at firing temperatures between 1,200degC and 1,450degC, enabling the clay body to become dense, glass-like, and highly durable. Earthenware firing occurs at much lower temperatures, usually between 1,000degC and 1,150degC, resulting in a more porous and less vitrified ceramic. The higher firing temperature of porcelain promotes full vitrification and translucency, whereas earthenware remains porous and opaque due to incomplete vitrification.

Surface Finish and Glaze Interaction

Porcelain vitrification occurs at higher temperatures, resulting in a denser, glass-like surface with a smooth and highly durable glaze interaction that enhances its translucency and resistance to moisture. In contrast, earthenware firing happens at lower temperatures, producing a more porous, matte surface where the glaze tends to sit on top, often leading to less uniform coverage and increased susceptibility to chipping. The vitrified porcelain's superior glaze adhesion and hardness make it ideal for fine tableware, while earthenware's surface finish offers a rustic aesthetic but with reduced functional durability.

Durability and Longevity Factors

Porcelain achieves higher vitrification due to its fine kaolin clay and firing at temperatures above 1,200degC, resulting in a dense, glass-like, and non-porous structure that significantly enhances durability and longevity. In contrast, earthenware is fired at lower temperatures (typically around 1,000-1,150degC), producing a more porous, less vitrified material that is more prone to chipping and water absorption, reducing its lifespan. This superior vitrification process in porcelain makes it ideal for items requiring long-term strength and resistance to wear.

Practical Applications of Vitrified Porcelain and Earthenware

Vitrified porcelain exhibits superior density and non-porosity, making it ideal for durable kitchenware and sanitary products that require resistance to liquids and stains. Earthenware, fired at lower temperatures, remains porous and is best suited for decorative items and indoor pottery where water absorption is less critical. Practical applications of vitrified porcelain extend to commercial tiles and tableware, while earthenware is often preferred for rustic garden pots and ornamental pieces.

Porcelain vitrification vs Earthenware firing Infographic

materialdif.com

materialdif.com