Porcelain enamel offers a durable, glass-like finish that is resistant to high temperatures, chemicals, and scratching, making it ideal for cookware and appliances. Powder coating provides a thicker, more flexible protective layer that can be applied in a wide range of colors and textures for metal surfaces. Both finishes enhance corrosion resistance, but porcelain enamel excels in longevity and heat resistance while powder coating stands out for ease of application and versatility.

Table of Comparison

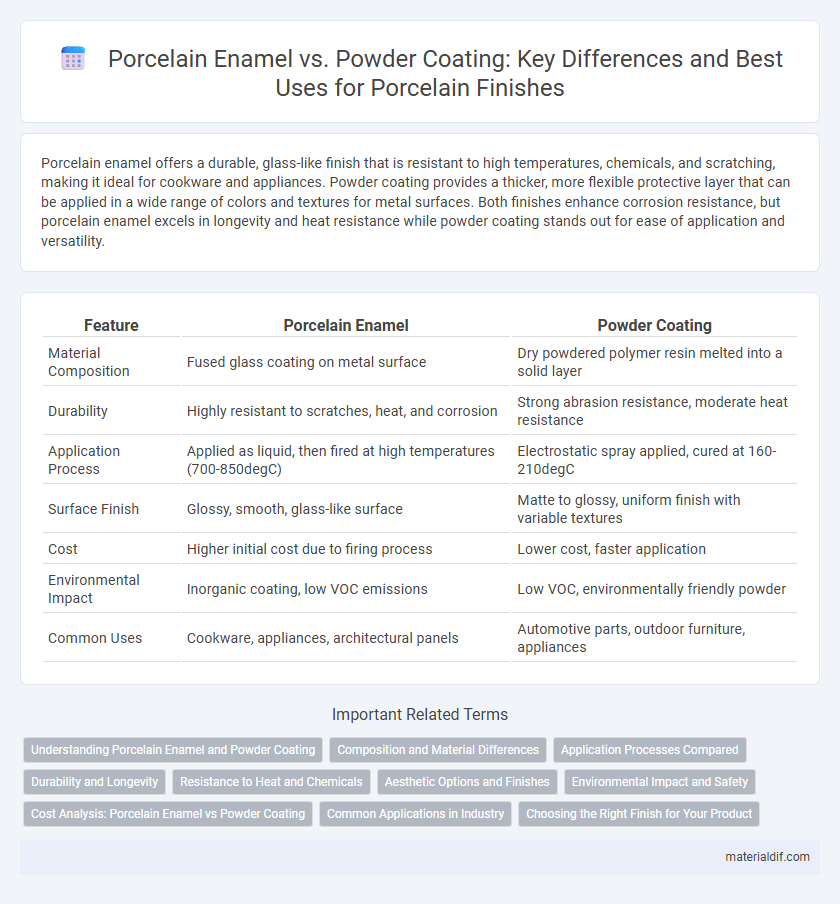

| Feature | Porcelain Enamel | Powder Coating |

|---|---|---|

| Material Composition | Fused glass coating on metal surface | Dry powdered polymer resin melted into a solid layer |

| Durability | Highly resistant to scratches, heat, and corrosion | Strong abrasion resistance, moderate heat resistance |

| Application Process | Applied as liquid, then fired at high temperatures (700-850degC) | Electrostatic spray applied, cured at 160-210degC |

| Surface Finish | Glossy, smooth, glass-like surface | Matte to glossy, uniform finish with variable textures |

| Cost | Higher initial cost due to firing process | Lower cost, faster application |

| Environmental Impact | Inorganic coating, low VOC emissions | Low VOC, environmentally friendly powder |

| Common Uses | Cookware, appliances, architectural panels | Automotive parts, outdoor furniture, appliances |

Understanding Porcelain Enamel and Powder Coating

Porcelain enamel is a glass-like coating fused onto metal at high temperatures, providing a durable, heat-resistant, and corrosion-proof surface often used in cookware and appliances. Powder coating involves applying a dry powder electrostatically onto metal, which is then cured under heat to create a tough, uniform, and protective finish suitable for automotive and industrial applications. Both processes enhance metal durability, but porcelain enamel offers superior resistance to scratching and chemical wear, while powder coating provides more color versatility and faster application.

Composition and Material Differences

Porcelain enamel consists of a glass-like coating fused onto metal through high-temperature firing, primarily composed of silica, feldspar, and borax, creating a durable and heat-resistant surface. Powder coating utilizes finely ground polymer resin particles, which are electrostatically sprayed and cured under heat to form a tough, flexible finish. The key material difference lies in porcelain enamel's inorganic, vitrified glass composition versus powder coating's organic, polymer-based makeup, influencing their durability, heat tolerance, and appearance.

Application Processes Compared

Porcelain enamel application involves fusing powdered glass to metal surfaces at temperatures between 1400degF and 1600degF, creating a durable and corrosion-resistant coating. Powder coating applies dry polymer powder electrostatically, followed by curing in an oven at around 350degF, resulting in a thick, uniform, and flexible finish. Porcelain enamel process requires higher heat and produces a harder surface, while powder coating offers faster turnaround and greater color variety with lower thermal impact on substrates.

Durability and Longevity

Porcelain enamel offers superior durability and longevity due to its glass-like coating fused to metal at high temperatures, providing excellent resistance to scratches, corrosion, and UV exposure. Powder coating, while durable and resistant to chipping and fading, generally wears down faster under harsh environmental conditions compared to porcelain enamel. This makes porcelain enamel the preferred choice for applications requiring long-term protection and minimal maintenance.

Resistance to Heat and Chemicals

Porcelain enamel offers superior resistance to high temperatures, often withstanding heat up to 1300degF (700degC) without degrading, making it ideal for applications involving intense heat exposure. It also provides excellent chemical resistance, maintaining durability against acids, alkalis, and solvents over time. Powder coating, while effective for moderate heat up to around 400degF (200degC), generally lacks the same robustness against extreme heat and harsh chemical environments, limiting its use in high-stress industrial settings.

Aesthetic Options and Finishes

Porcelain enamel offers a smooth, glass-like finish with vibrant, long-lasting colors and a high resistance to fading, making it ideal for decorative applications requiring a glossy or matte surface. Powder coating provides a more versatile range of textures, from matte to high gloss, with the ability to customize colors and thickness, allowing for durable, uniform finishes suitable for both industrial and aesthetic purposes. Both finishes enhance surface protection, but porcelain enamel excels in maintaining its aesthetic appeal under extreme weather and chemical exposure.

Environmental Impact and Safety

Porcelain enamel coating is made from natural minerals fused at high temperatures, resulting in a durable, non-toxic, and recyclable surface that resists chipping and corrosion without releasing harmful VOCs. Powder coating involves applying a dry polymer powder baked at moderate temperatures, producing fewer emissions and waste since overspray can be reclaimed, but some powders may contain hazardous chemicals requiring careful handling. Both methods prioritize environmental safety, with porcelain enamel offering superior inertness and powder coating providing efficient material use and lower air pollution during application.

Cost Analysis: Porcelain Enamel vs Powder Coating

Porcelain enamel generally involves higher initial costs due to the specialized firing process and raw materials like borosilicate glass mixed with clay, resulting in a durable, long-lasting finish. Powder coating offers a more cost-effective application with lower labor and energy expenses, utilizing powdered resin cured under heat to form a protective layer, but may require more frequent maintenance or reapplication over time. Evaluating total lifecycle costs, including durability, maintenance, and replacement frequency, is essential when comparing porcelain enamel and powder coating for budget-sensitive projects.

Common Applications in Industry

Porcelain enamel is widely used in cookware, sanitary ware, and industrial equipment requiring high heat resistance and durability, such as ovens and chemical tanks. Powder coating finds common applications in automotive parts, metal furniture, and appliances due to its excellent corrosion protection and flexibility in color finishes. Both coatings provide protective and decorative surfaces but are selected based on performance needs like temperature resistance or impact durability in specific industrial settings.

Choosing the Right Finish for Your Product

Porcelain enamel offers a durable, glass-like coating ideal for heat resistance and chemical durability, making it perfect for cookware and industrial equipment. Powder coating provides a versatile, cost-effective finish with excellent impact resistance and color variety, suitable for automotive and outdoor applications. Selecting the right finish depends on factors such as environmental exposure, desired aesthetics, and durability requirements specific to the product's use case.

Porcelain Enamel vs Powder Coating Infographic

materialdif.com

materialdif.com