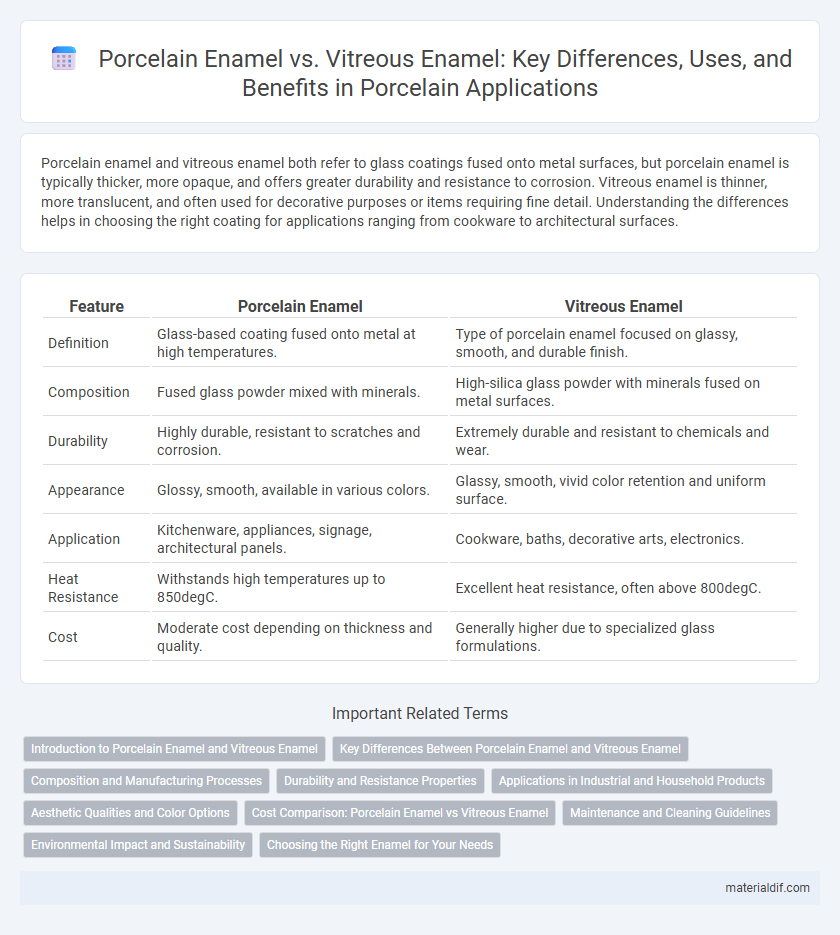

Porcelain enamel and vitreous enamel both refer to glass coatings fused onto metal surfaces, but porcelain enamel is typically thicker, more opaque, and offers greater durability and resistance to corrosion. Vitreous enamel is thinner, more translucent, and often used for decorative purposes or items requiring fine detail. Understanding the differences helps in choosing the right coating for applications ranging from cookware to architectural surfaces.

Table of Comparison

| Feature | Porcelain Enamel | Vitreous Enamel |

|---|---|---|

| Definition | Glass-based coating fused onto metal at high temperatures. | Type of porcelain enamel focused on glassy, smooth, and durable finish. |

| Composition | Fused glass powder mixed with minerals. | High-silica glass powder with minerals fused on metal surfaces. |

| Durability | Highly durable, resistant to scratches and corrosion. | Extremely durable and resistant to chemicals and wear. |

| Appearance | Glossy, smooth, available in various colors. | Glassy, smooth, vivid color retention and uniform surface. |

| Application | Kitchenware, appliances, signage, architectural panels. | Cookware, baths, decorative arts, electronics. |

| Heat Resistance | Withstands high temperatures up to 850degC. | Excellent heat resistance, often above 800degC. |

| Cost | Moderate cost depending on thickness and quality. | Generally higher due to specialized glass formulations. |

Introduction to Porcelain Enamel and Vitreous Enamel

Porcelain enamel is a durable coating made by fusing powdered glass to metal at high temperatures, creating a smooth, glossy surface resistant to corrosion, heat, and chemicals. Vitreous enamel, often used interchangeably with porcelain enamel, specifically refers to the vitreous, glass-like coating formed through this process, characterized by its glassy, non-porous finish that enhances metal substrates. Both materials share similar manufacturing techniques and properties but can vary in composition and thickness depending on application requirements in industries such as cookware, electrical insulation, and architectural panels.

Key Differences Between Porcelain Enamel and Vitreous Enamel

Porcelain enamel is a type of vitreous enamel characterized by its pure, glassy coating fused at high temperatures on metal surfaces, often used for cookware and appliances due to its durability and smooth finish. Vitreous enamel refers broadly to the glass-like coating created by fusing powdered glass to a substrate, which may include various formulations beyond porcelain enamel, allowing for diverse applications and colors. The key differences lie in their composition, firing temperature, finish quality, and specific use cases, with porcelain enamel typically offering a thicker, more uniform, and corrosion-resistant coating compared to broader vitreous enamel varieties.

Composition and Manufacturing Processes

Porcelain enamel is a type of vitreous enamel primarily composed of powdered glass fused onto metal at high temperatures, creating a smooth, durable coating. Vitreous enamel also consists of silica, fluxes, and metal oxides, but its formulation can vary to achieve different colors and textures during the kiln-firing process. Manufacturing porcelain enamel involves applying the glass frit onto a metal substrate followed by controlled firing, while vitreous enamel processes may include additional steps like grinding and polishing to enhance the finish and performance.

Durability and Resistance Properties

Porcelain enamel offers superior durability with a glassy, non-porous coating that resists chipping, scratching, and chemical corrosion, making it ideal for heavy-duty applications. Vitreous enamel, composed of powdered glass fused to metal at high temperatures, provides excellent hardness and thermal resistance but can be more prone to cracking under rapid temperature changes. Both coatings ensure long-lasting protection, yet porcelain enamel excels in maintaining integrity under mechanical stress and harsh environmental conditions.

Applications in Industrial and Household Products

Porcelain enamel, known for its durability and resistance to corrosion, is commonly used in industrial equipment such as chemical tanks, heat exchangers, and cookware due to its strong glassy coating that withstands high temperatures and impacts. Vitreous enamel, a subtype of porcelain enamel, offers a smoother, more refined finish ideal for household products like kitchen utensils, bathtubs, and decorative appliances, where aesthetic appeal and easy cleaning are important. Both materials provide excellent protection against wear and chemical exposure, making them suitable for a wide range of industrial and household applications.

Aesthetic Qualities and Color Options

Porcelain enamel offers a smooth, glossy finish with a rich depth of color, making it ideal for vibrant and uniform aesthetic applications. Vitreous enamel, composed of powdered glass fused onto metal, provides a highly durable surface with a slightly textured appearance and a broad range of color choices, including translucent and opaque shades. Both materials excel in color retention and resistance to fading, though porcelain enamel typically yields a more consistent, glass-like sheen preferred for high-end decorative uses.

Cost Comparison: Porcelain Enamel vs Vitreous Enamel

Porcelain enamel typically costs less than vitreous enamel due to differences in raw materials and firing processes, making it a more budget-friendly option for coating metal surfaces. Vitreous enamel involves higher-grade materials and multiple kiln firings, which increase manufacturing expenses and result in a premium price point. Cost-efficiency analysis often favors porcelain enamel for large-scale applications, while vitreous enamel is chosen for durability despite its higher initial investment.

Maintenance and Cleaning Guidelines

Porcelain enamel offers a durable, non-porous surface resistant to stains and scratches, making it easier to clean with mild detergents and non-abrasive sponges. Vitreous enamel requires gentle handling to avoid chipping; cleaning should involve soft cloths and pH-neutral cleaners to maintain its glossy finish. Both materials benefit from prompt stain removal to prevent chemical bonding and maintain their aesthetic and functional qualities.

Environmental Impact and Sustainability

Porcelain enamel and vitreous enamel differ in environmental impact, with porcelain enamel generally requiring higher firing temperatures, leading to increased energy consumption and carbon emissions. Vitreous enamel, often formulated with fewer toxic raw materials and lower firing requirements, tends to offer improved sustainability profiles. Both coatings provide durable, long-lasting surfaces that reduce the need for frequent replacements, supporting sustainable material use in various industries.

Choosing the Right Enamel for Your Needs

Porcelain enamel and vitreous enamel both offer durable, glass-like coatings fused to metal surfaces, but they differ in composition and application. Porcelain enamel has a higher silica content, making it more resistant to scratching and ideal for cookware and decorative items, while vitreous enamel, often used in industrial and architectural applications, provides superior thermal and chemical resistance. Selecting the right enamel depends on the specific requirements for durability, heat tolerance, and aesthetic appeal in your project.

Porcelain Enamel vs Vitreous Enamel Infographic

materialdif.com

materialdif.com