Porcelain body staining involves discoloration within the ceramic material itself, affecting the entire body and resulting in permanent color changes that impact durability and appearance. Surface decoration refers to applied designs, such as glazing or painting, which rest on the exterior and can wear off or chip over time without altering the underlying porcelain body. Understanding the distinction aids in selecting restoration methods and assessing the longevity of porcelain pet figurines.

Table of Comparison

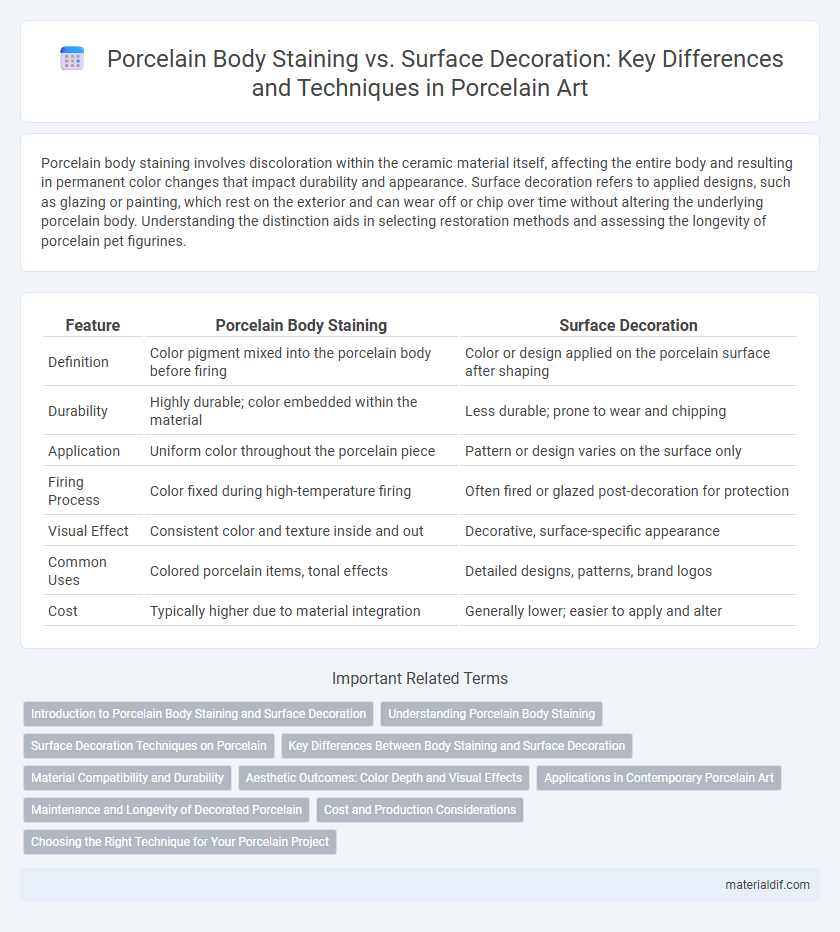

| Feature | Porcelain Body Staining | Surface Decoration |

|---|---|---|

| Definition | Color pigment mixed into the porcelain body before firing | Color or design applied on the porcelain surface after shaping |

| Durability | Highly durable; color embedded within the material | Less durable; prone to wear and chipping |

| Application | Uniform color throughout the porcelain piece | Pattern or design varies on the surface only |

| Firing Process | Color fixed during high-temperature firing | Often fired or glazed post-decoration for protection |

| Visual Effect | Consistent color and texture inside and out | Decorative, surface-specific appearance |

| Common Uses | Colored porcelain items, tonal effects | Detailed designs, patterns, brand logos |

| Cost | Typically higher due to material integration | Generally lower; easier to apply and alter |

Introduction to Porcelain Body Staining and Surface Decoration

Porcelain body staining involves incorporating colorants directly into the ceramic body before firing, creating uniform coloration throughout the material, whereas surface decoration applies pigments, glazes, or decals on the exterior after the porcelain has been formed or fired. Body staining enhances durability and resists surface wear, making it ideal for functional ware, while surface decoration offers greater artistic flexibility and intricate designs. Understanding the differences helps in selecting techniques that optimize both aesthetic appeal and functional performance in porcelain production.

Understanding Porcelain Body Staining

Porcelain body staining involves incorporating colorants directly into the clay body, creating uniform color throughout the material and enhancing durability. This technique differs from surface decoration, which applies pigments or glazes only on the exterior, often making these details more vulnerable to wear. Understanding porcelain body staining is essential for achieving consistent hues and long-lasting finishes in ceramics.

Surface Decoration Techniques on Porcelain

Surface decoration techniques on porcelain include underglaze painting, overglaze enameling, and transfer printing, each contributing distinct aesthetic qualities and durability to the final piece. Underglaze painting involves applying pigments before the glaze firing, resulting in colors that are embedded beneath a glassy surface, enhancing resistance to wear and fading. Overglaze enameling is applied after the initial glaze firing, allowing for vivid detail and layering but requiring additional firing at lower temperatures to fuse the decoration without damaging the body.

Key Differences Between Body Staining and Surface Decoration

Porcelain body staining involves incorporating colorants directly into the clay body, resulting in consistent coloration throughout the material that enhances durability and resists wear. Surface decoration applies pigments, glazes, or decals on the porcelain's exterior, providing detailed visual effects but potentially vulnerable to scratches and fading over time. Key differences lie in the permanence of body staining versus the variability and fragility of surface decoration techniques.

Material Compatibility and Durability

Porcelain body staining involves integrating pigments into the clay mixture, resulting in consistent coloration throughout the material that enhances durability and resists surface wear. Surface decoration applies colors or patterns onto the finished porcelain, which may be more susceptible to chipping and fading due to less material integration. Understanding material compatibility between stains and porcelain clay is crucial for achieving long-lasting finishes, as improperly matched pigments can lead to cracking or discoloration during firing.

Aesthetic Outcomes: Color Depth and Visual Effects

Porcelain body staining integrates color directly into the clay, resulting in rich, deep hues that maintain consistency even if the surface wears over time, enhancing the overall color depth and permanence. Surface decoration techniques, such as glazing or painting, offer vibrant visual effects and intricate designs but may risk fading or chipping with use and exposure. This distinction impacts aesthetic outcomes, where body staining provides durability and subtlety, while surface decoration emphasizes boldness and detailed artistry.

Applications in Contemporary Porcelain Art

Porcelain body staining involves integrating color pigments within the clay matrix, enhancing the structural depth and durability of the artwork, making it ideal for sculptural contemporary porcelain pieces. Surface decoration techniques, such as glazing, overglaze painting, and decal application, provide vibrant visual effects and intricate designs that are prominent in functional and aesthetic porcelain objects. These distinct methods allow contemporary artists to explore innovative textures and colors, expanding creative possibilities in porcelain art.

Maintenance and Longevity of Decorated Porcelain

Porcelain body staining penetrates deep into the ceramic matrix, offering superior durability and resistance to fading compared to surface decoration, which remains more vulnerable to abrasion and chipping. Maintenance of body-stained porcelain involves simple cleaning without the risk of losing color or design integrity, while surface-decorated porcelain requires careful handling and specialized cleaning products to preserve its appearance. Longevity of decorated porcelain is significantly enhanced by using body staining techniques, making it ideal for high-traffic or frequently cleaned applications.

Cost and Production Considerations

Porcelain body staining involves integrating colorants into the clay mixture, resulting in consistent coloration throughout the piece but increasing raw material costs and requiring specialized mixing equipment, which extends production time. Surface decoration, such as glazing or painting, offers greater design flexibility at a lower material expense but adds additional steps like firing and labor-intensive detailing, affecting overall manufacturing efficiency. Cost considerations favor surface decoration for mass production, while body staining suits high-end or artistic porcelain with longer production cycles.

Choosing the Right Technique for Your Porcelain Project

Porcelain body staining involves incorporating color directly into the clay, creating consistent hues throughout the piece that resist scratching or wear, ideal for heavily used items or intricate shapes. Surface decoration applies glazes, paints, or decals on the exterior, allowing for detailed designs and textures but is more susceptible to chipping over time. Selecting the right technique depends on the intended use, desired aesthetic durability, and firing compatibility with the porcelain body's chemical composition.

Porcelain Body Staining vs Surface Decoration Infographic

materialdif.com

materialdif.com