Porcelain bodies are made from refined kaolin clay and fired at high temperatures, resulting in a dense, translucent, and vitrified material known for its strength and delicate appearance. Earthenware bodies consist of more porous, less refined clays fired at lower temperatures, leading to a more porous, opaque, and less durable ceramic with a rustic charm. The key differences lie in their composition, firing temperature, and resulting physical properties, influencing their use in fine china versus everyday pottery.

Table of Comparison

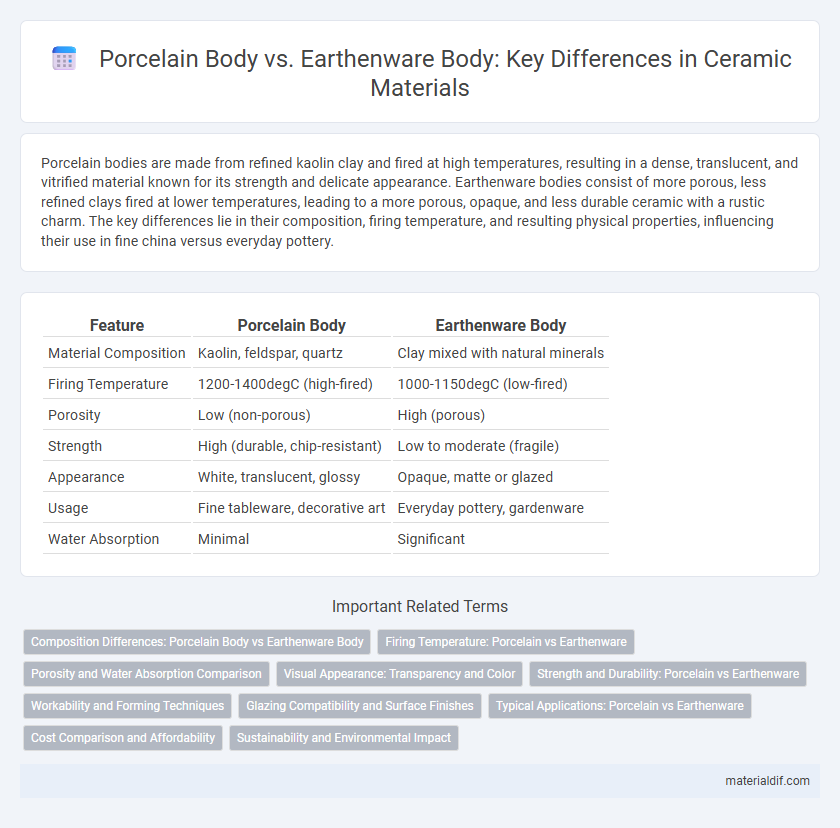

| Feature | Porcelain Body | Earthenware Body |

|---|---|---|

| Material Composition | Kaolin, feldspar, quartz | Clay mixed with natural minerals |

| Firing Temperature | 1200-1400degC (high-fired) | 1000-1150degC (low-fired) |

| Porosity | Low (non-porous) | High (porous) |

| Strength | High (durable, chip-resistant) | Low to moderate (fragile) |

| Appearance | White, translucent, glossy | Opaque, matte or glazed |

| Usage | Fine tableware, decorative art | Everyday pottery, gardenware |

| Water Absorption | Minimal | Significant |

Composition Differences: Porcelain Body vs Earthenware Body

Porcelain body primarily consists of kaolin, quartz, and feldspar, which provide its characteristic strength, translucency, and high firing temperature. In contrast, earthenware body contains more iron and other impurities, resulting in a porous, softer material fired at lower temperatures. The distinct mineral composition directly influences their durability, color, and suitability for fine or utilitarian ceramics.

Firing Temperature: Porcelain vs Earthenware

Porcelain body is typically fired at a higher temperature range of 1300degC to 1450degC, resulting in a denser, vitrified, and non-porous ceramic material. In contrast, earthenware body is fired at lower temperatures between 1000degC and 1150degC, leading to a more porous, softer, and less durable ceramic that often requires glazing for waterproofing. The higher firing temperature of porcelain enhances its strength, translucency, and resistance to thermal shock compared to earthenware.

Porosity and Water Absorption Comparison

Porcelain body is characterized by low porosity and minimal water absorption rates, usually less than 0.5%, making it highly durable and resistant to moisture. In contrast, earthenware body exhibits higher porosity with water absorption values often exceeding 5%, resulting in less durability and greater susceptibility to water damage. This significant difference in porosity and water absorption directly influences the functional performance and application of porcelain versus earthenware ceramics.

Visual Appearance: Transparency and Color

Porcelain body is characterized by its translucent quality, allowing light to pass through, which creates a delicate, almost ethereal appearance, often in shades of white or pale cream. Earthenware body is opaque and typically demonstrates a more rustic, earthy color palette ranging from reddish-brown to buff due to higher iron content. The color and transparency differences result from the differing mineral compositions and firing temperatures of porcelain and earthenware.

Strength and Durability: Porcelain vs Earthenware

Porcelain body exhibits superior strength and durability compared to earthenware body due to its dense, vitrified structure achieved at higher firing temperatures, typically above 1200degC. Earthenware body, fired at lower temperatures around 1000-1150degC, remains more porous and less resilient, making it prone to chipping and cracking. The inherent toughness and non-porous nature of porcelain contribute to its enhanced mechanical performance and long-lasting quality in functional and decorative applications.

Workability and Forming Techniques

Porcelain body offers superior workability due to its fine particle size and higher plasticity, allowing for delicate shaping and intricate detailing through techniques like wheel throwing and slip casting. Earthenware body, with coarser particles and lower plasticity, is better suited for hand-building methods such as coiling and slab construction but is less adaptable to fine, precise forms. These differences in material properties directly influence the choice of forming techniques and the complexity of finished ceramic pieces.

Glazing Compatibility and Surface Finishes

Porcelain bodies exhibit superior glazing compatibility due to their dense, vitrified structure, enabling smooth, glass-like surface finishes that resist chipping and discoloration. In contrast, earthenware bodies, being more porous and less vitrified, often require specialized glazes to prevent absorption issues, resulting in softer, matte finishes prone to wear. The choice between porcelain and earthenware significantly impacts the durability and aesthetic quality of the final glazed product.

Typical Applications: Porcelain vs Earthenware

Porcelain body boasts high strength and a non-porous surface, making it ideal for fine dinnerware, decorative art pieces, and laboratory equipment that require durability and a smooth finish. Earthenware body, characterized by its porous and coarse texture, is commonly used for rustic pottery, garden pots, and casual tableware where affordability and ease of shaping are prioritized. Typical applications highlight porcelain's suitability for elegant, high-end products, whereas earthenware serves utilitarian and decorative purposes with a focus on traditional craftsmanship.

Cost Comparison and Affordability

Porcelain body is typically more expensive than earthenware body due to its refined materials like kaolin and the higher firing temperatures required, which increase production costs. Earthenware body offers greater affordability by using more abundant clays and lower firing temperatures, making it accessible for budget-conscious consumers. The cost difference highlights porcelain's premium quality against earthenware's budget-friendly appeal in tableware and decorative ceramics.

Sustainability and Environmental Impact

Porcelain bodies, composed primarily of kaolin, feldspar, and quartz, exhibit lower porosity and higher durability compared to earthenware bodies, reducing the need for frequent replacement and thereby minimizing waste. Earthenware bodies typically require lower firing temperatures, resulting in less energy consumption during production, but their higher absorption rates can lead to quicker degradation and increased environmental impact over time. Selecting porcelain can support long-term sustainability through its enhanced lifespan, while earthenware's lower initial energy use must be balanced against ongoing environmental costs.

Porcelain Body vs Earthenware Body Infographic

materialdif.com

materialdif.com