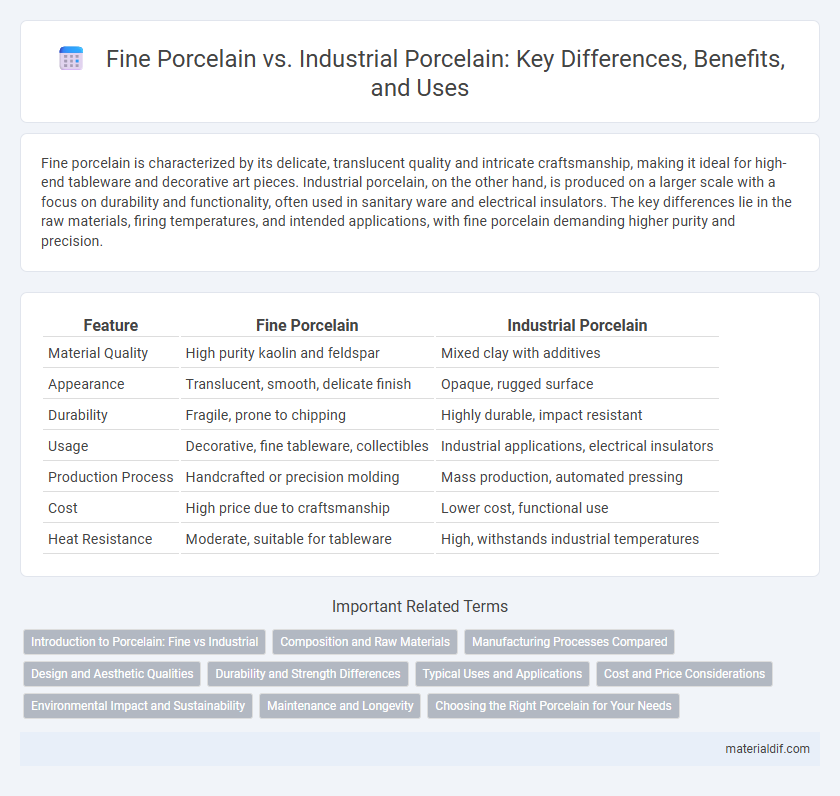

Fine porcelain is characterized by its delicate, translucent quality and intricate craftsmanship, making it ideal for high-end tableware and decorative art pieces. Industrial porcelain, on the other hand, is produced on a larger scale with a focus on durability and functionality, often used in sanitary ware and electrical insulators. The key differences lie in the raw materials, firing temperatures, and intended applications, with fine porcelain demanding higher purity and precision.

Table of Comparison

| Feature | Fine Porcelain | Industrial Porcelain |

|---|---|---|

| Material Quality | High purity kaolin and feldspar | Mixed clay with additives |

| Appearance | Translucent, smooth, delicate finish | Opaque, rugged surface |

| Durability | Fragile, prone to chipping | Highly durable, impact resistant |

| Usage | Decorative, fine tableware, collectibles | Industrial applications, electrical insulators |

| Production Process | Handcrafted or precision molding | Mass production, automated pressing |

| Cost | High price due to craftsmanship | Lower cost, functional use |

| Heat Resistance | Moderate, suitable for tableware | High, withstands industrial temperatures |

Introduction to Porcelain: Fine vs Industrial

Fine porcelain, often referred to as bone china or hard-paste porcelain, is characterized by its translucency, high whiteness, and delicate, lightweight nature, making it prized for artistic and luxury tableware. Industrial porcelain, in contrast, prioritizes durability, density, and resistance to thermal shock, serving functional roles in electrical insulators, sanitary ware, and mechanical components. Both types share a base composition of kaolin, feldspar, and quartz but differ in firing temperature and additive materials, affecting their physical properties and applications.

Composition and Raw Materials

Fine porcelain is made from high-quality kaolin clay, feldspar, and quartz, resulting in a translucent, delicate, and highly vitrified material prized for its whiteness and strength. Industrial porcelain incorporates similar raw materials but often includes additional additives such as ball clay and talc to enhance durability and reduce production costs. The precise composition differences influence firing temperature and final product characteristics, with fine porcelain requiring higher temperatures for its refined texture compared to industrial variants.

Manufacturing Processes Compared

Fine porcelain is crafted through meticulous handcrafting techniques involving high-quality kaolin, feldspar, and quartz, undergoing multiple firings at temperatures around 1,300degC to achieve translucency and delicate aesthetics. Industrial porcelain relies on automated production lines with precise control over raw material mixing, shaping, and lower temperature firings, typically around 1,200degC, prioritizing durability and mass production efficiency. The contrast in manufacturing processes results in fine porcelain featuring refined textures and artistic value, while industrial porcelain emphasizes consistency and cost-effectiveness.

Design and Aesthetic Qualities

Fine porcelain, characterized by its translucent quality and delicate craftsmanship, offers intricate designs with smooth, refined surfaces that enhance visual appeal and elegance. Industrial porcelain, produced on a larger scale, emphasizes durability and uniformity, often featuring simpler patterns and matte finishes suitable for functional purposes. The superior aesthetic qualities of fine porcelain make it highly prized for decorative art and luxury tableware.

Durability and Strength Differences

Fine porcelain, known for its translucency and refined texture, tends to be less durable under heavy impact due to its thinner composition and higher firing temperature, making it ideal for delicate tableware and decorative items. Industrial porcelain, manufactured with denser clay mixtures and fired at even higher temperatures, offers superior strength and resistance to chipping and thermal shock, making it suitable for engineering applications and heavy-duty uses. The durability of industrial porcelain is enhanced by its lower porosity and increased mechanical strength, whereas fine porcelain prioritizes aesthetic qualities over toughness.

Typical Uses and Applications

Fine porcelain, known for its translucency and delicate finish, is predominantly used in luxury dinnerware, decorative art pieces, and high-end sanitary ware, prized for its aesthetic appeal and refined texture. Industrial porcelain, characterized by higher durability and resistance to thermal shock, finds extensive applications in electrical insulators, laboratory equipment, and heavy-duty tiles where mechanical strength and functionality are critical. While fine porcelain excels in ornamental and household contexts, industrial porcelain is integral to manufacturing and infrastructure requiring robust material performance.

Cost and Price Considerations

Fine porcelain typically commands higher prices due to its meticulous craftsmanship, premium raw materials, and delicate finishing processes, making it a luxury item sought after by collectors. Industrial porcelain, produced in large volumes using automated methods, offers more affordable pricing suitable for mass-market applications without compromising basic durability. Cost considerations for buyers hinge on intended use, with fine porcelain favored for decorative or high-end functional pieces and industrial porcelain preferred for everyday durability and cost-efficiency.

Environmental Impact and Sustainability

Fine porcelain production typically involves higher energy consumption and uses natural resources more intensively, raising environmental concerns despite its durability and longevity. Industrial porcelain manufacturing often incorporates recycled materials and advanced technologies to reduce waste and lower carbon emissions, promoting greater sustainability. The ecological footprint of fine porcelain is generally larger compared to industrial porcelain, which benefits from scalable processes designed to minimize environmental impact.

Maintenance and Longevity

Fine porcelain exhibits superior durability and requires delicate maintenance to preserve its intricate craftsmanship, often involving gentle handwashing and careful handling to avoid chipping or cracking. Industrial porcelain, designed for mass production, offers enhanced resistance to wear, temperature fluctuations, and staining, enabling easier cleaning and longer service life in high-traffic environments. The longevity of fine porcelain depends heavily on meticulous upkeep, whereas industrial porcelain sustains its structural integrity with minimal maintenance demands.

Choosing the Right Porcelain for Your Needs

Fine porcelain offers superior translucency, delicate craftsmanship, and higher resistance to chipping, making it ideal for decorative items and elegant tableware. Industrial porcelain provides enhanced durability, thermal shock resistance, and cost-effectiveness suited for commercial settings and heavy-use applications. Selecting the right porcelain depends on balancing aesthetic appeal with functional demands, where fine porcelain excels in artistry while industrial porcelain outperforms in practical resilience.

Fine Porcelain vs Industrial Porcelain Infographic

materialdif.com

materialdif.com