Porcelain stoneware is a dense, durable material fired at high temperatures, making it resistant to water and wear, ideal for flooring and heavy-use surfaces. Porcelain earthenware, on the other hand, is more porous and less durable, fired at lower temperatures, suitable mainly for decorative items or light-use tableware. The key difference lies in their composition and firing process, influencing their strength and application.

Table of Comparison

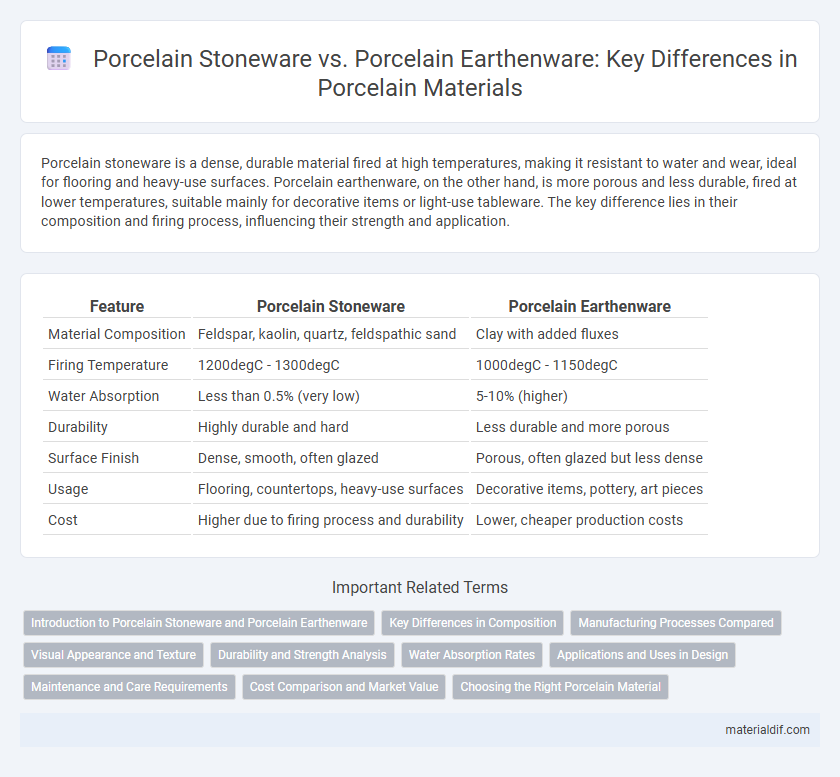

| Feature | Porcelain Stoneware | Porcelain Earthenware |

|---|---|---|

| Material Composition | Feldspar, kaolin, quartz, feldspathic sand | Clay with added fluxes |

| Firing Temperature | 1200degC - 1300degC | 1000degC - 1150degC |

| Water Absorption | Less than 0.5% (very low) | 5-10% (higher) |

| Durability | Highly durable and hard | Less durable and more porous |

| Surface Finish | Dense, smooth, often glazed | Porous, often glazed but less dense |

| Usage | Flooring, countertops, heavy-use surfaces | Decorative items, pottery, art pieces |

| Cost | Higher due to firing process and durability | Lower, cheaper production costs |

Introduction to Porcelain Stoneware and Porcelain Earthenware

Porcelain stoneware is a dense, highly durable ceramic material fired at extremely high temperatures, making it ideal for heavy-duty flooring and wall applications where resistance to scratches and stains is essential. Porcelain earthenware, slightly more porous and fired at lower temperatures, offers a more delicate finish suited for decorative items, tableware, and indoor wall tiles with intricate designs. Understanding the differences in firing temperature, porosity, and durability helps determine the optimal use of porcelain stoneware or earthenware in various architectural and decorative projects.

Key Differences in Composition

Porcelain stoneware is made from a mixture of kaolin, feldspar, and quartz, resulting in a denser, more vitrified body that offers superior durability and water resistance. Porcelain earthenware contains higher amounts of clay and is less vitrified, making it more porous and less durable compared to stoneware. The key compositional difference lies in the firing temperature and mineral content, with stoneware fired at higher temperatures, producing a harder, non-porous surface ideal for heavy use.

Manufacturing Processes Compared

Porcelain stoneware is manufactured through high-temperature vitrification, involving the sintering of dense, fine-grained clays and feldspar to produce a highly durable, non-porous surface. Porcelain earthenware undergoes a lower temperature firing process, resulting in a more porous material with a softer, less dense body due to the inclusion of grog and less refined clays. The critical difference in manufacturing lies in the firing temperature and clay composition, which directly affect the strength, water absorption, and translucency of the final products.

Visual Appearance and Texture

Porcelain stoneware exhibits a dense, smooth surface with a polished finish that enhances its sleek, modern aesthetic, often resembling natural stone. In contrast, porcelain earthenware has a slightly porous and matte texture, offering a warmer, more traditional look with subtle color variations and softer edges. The visual appearance of stoneware is characterized by uniformity and durability, while earthenware showcases artisanal charm and textured depth.

Durability and Strength Analysis

Porcelain stoneware exhibits superior durability and strength compared to porcelain earthenware due to its higher firing temperature, resulting in a denser, less porous structure. This makes stoneware highly resistant to chipping, cracking, and thermal shock, ideal for heavy-use environments. In contrast, porcelain earthenware, while aesthetically appealing, tends to be more fragile and susceptible to wear and moisture absorption over time.

Water Absorption Rates

Porcelain stoneware exhibits an exceptionally low water absorption rate, typically below 0.5%, making it highly resistant to moisture and ideal for outdoor and high-traffic environments. In contrast, porcelain earthenware shows a higher water absorption rate around 3-6%, which reduces its durability and limits its use to indoor applications. These differences in porosity directly impact the performance, maintenance, and longevity of each material in various architectural and design projects.

Applications and Uses in Design

Porcelain stoneware offers exceptional strength and low porosity, making it ideal for high-traffic commercial flooring and outdoor applications where durability and resistance to wear are critical. Porcelain earthenware, characterized by its more porous body and delicate glaze, is commonly used in decorative tiles, tableware, and artistic installations where aesthetic appeal and fine detailing are prioritized. Designers select porcelain stoneware for functional environments and porcelain earthenware for intricate design elements that benefit from its refined texture and color variations.

Maintenance and Care Requirements

Porcelain stoneware demands minimal maintenance due to its low porosity and high resistance to stains, scratches, and chemicals, making it ideal for high-traffic areas. Porcelain earthenware, while aesthetically appealing, is more porous and susceptible to chipping and staining, requiring regular sealing and gentler cleaning agents to preserve its finish. Proper care methods tailored to each type ensure longevity and maintain their visual and structural integrity.

Cost Comparison and Market Value

Porcelain stoneware generally commands a higher market value due to its superior durability, low porosity, and resistance to scratches and stains, making it ideal for high-traffic and commercial spaces. Porcelain earthenware is more cost-effective, offering a softer, more porous material suited for decorative applications and low-traffic areas, which limits its market appeal and resale value. The price gap between these types reflects their material composition and performance, with stoneware often priced 20-40% higher than earthenware in retail and bulk markets.

Choosing the Right Porcelain Material

Porcelain stoneware offers exceptional durability and low water absorption, making it ideal for high-traffic areas and outdoor use, whereas porcelain earthenware features a more porous texture suitable for decorative items and indoor applications. When choosing the right porcelain material, consider the specific demands of your project, such as strength, aesthetics, and moisture resistance. The denser composition of porcelain stoneware provides superior scratch resistance and longevity compared to the more delicate porcelain earthenware.

Porcelain Stoneware vs Porcelain Earthenware Infographic

materialdif.com

materialdif.com