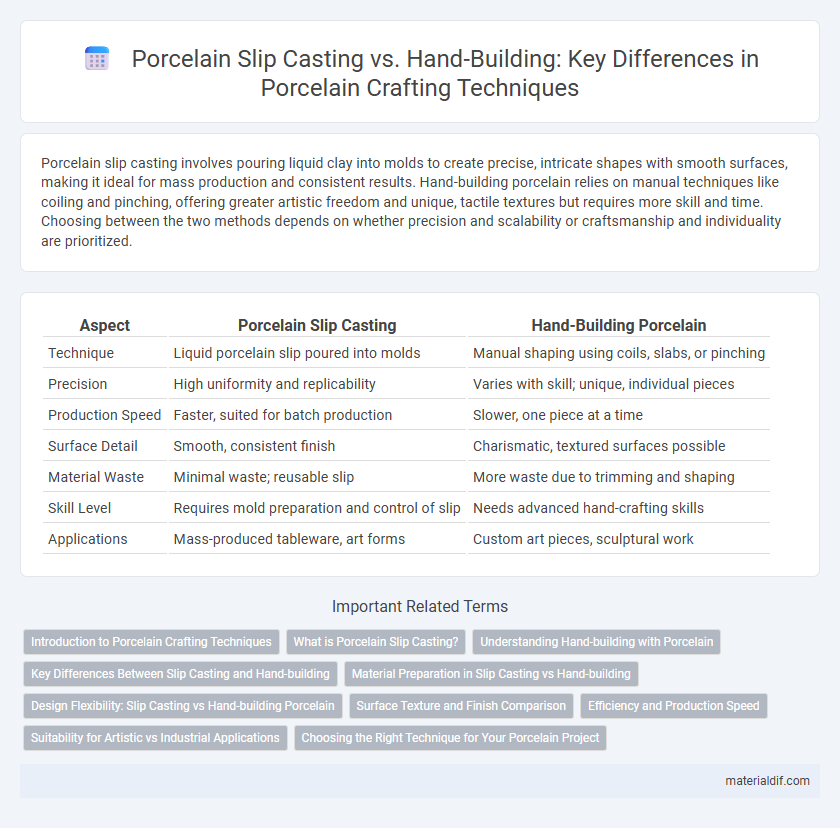

Porcelain slip casting involves pouring liquid clay into molds to create precise, intricate shapes with smooth surfaces, making it ideal for mass production and consistent results. Hand-building porcelain relies on manual techniques like coiling and pinching, offering greater artistic freedom and unique, tactile textures but requires more skill and time. Choosing between the two methods depends on whether precision and scalability or craftsmanship and individuality are prioritized.

Table of Comparison

| Aspect | Porcelain Slip Casting | Hand-Building Porcelain |

|---|---|---|

| Technique | Liquid porcelain slip poured into molds | Manual shaping using coils, slabs, or pinching |

| Precision | High uniformity and replicability | Varies with skill; unique, individual pieces |

| Production Speed | Faster, suited for batch production | Slower, one piece at a time |

| Surface Detail | Smooth, consistent finish | Charismatic, textured surfaces possible |

| Material Waste | Minimal waste; reusable slip | More waste due to trimming and shaping |

| Skill Level | Requires mold preparation and control of slip | Needs advanced hand-crafting skills |

| Applications | Mass-produced tableware, art forms | Custom art pieces, sculptural work |

Introduction to Porcelain Crafting Techniques

Porcelain slip casting involves pouring liquid clay slip into plaster molds to create precise, uniform shapes ideal for intricate designs and mass production. Hand-building porcelain uses manual methods such as pinching, coiling, and slab construction, offering greater artistic freedom and unique, one-of-a-kind pieces. Both techniques require mastery of porcelain's fine particle composition and high firing temperatures to achieve its characteristic translucency and strength.

What is Porcelain Slip Casting?

Porcelain slip casting is a ceramic forming technique where liquid clay, or slip, is poured into plaster molds to create detailed and uniform porcelain pieces. This method allows for high precision and reproducibility, making it ideal for intricate shapes that are difficult to achieve with hand-building. Slip casting also reduces the risk of air bubbles and structural weaknesses often encountered in hand-built porcelain items.

Understanding Hand-building with Porcelain

Hand-building with porcelain involves manipulating soft clay using techniques such as pinching, coiling, and slab construction to create intricate, one-of-a-kind forms. This method requires mastery of porcelain's delicate plasticity and drying properties to prevent cracking and warping during the drying and firing stages. Compared to slip casting, hand-building allows for greater artistic expression and tactile control, making it ideal for unique, sculptural porcelain pieces.

Key Differences Between Slip Casting and Hand-building

Porcelain slip casting involves pouring liquid clay slip into a plaster mold, allowing for precise replication of complex shapes and fine details, whereas hand-building porcelain requires manual shaping through techniques like pinching, coiling, or slab construction, emphasizing artisanal control and texture. Slip casting offers consistent wall thickness and smooth surfaces ideal for mass production, while hand-building allows for unique, one-of-a-kind pieces with more tactile and sculptural qualities. The drying and firing processes differ as well, with slip casting pieces generally experiencing less warping due to uniform thickness compared to the variable thickness common in hand-built porcelain.

Material Preparation in Slip Casting vs Hand-building

Porcelain slip casting involves preparing a liquid clay mixture called slip, which is carefully sieved to achieve a smooth, consistent texture essential for uniform thickness and fine detail in molds. In contrast, hand-building porcelain requires kneading and wedging solid clay to remove air bubbles and achieve a pliable, workable consistency, allowing for more tactile control but demanding greater skill for evenness. The slip casting process emphasizes precision in slurry viscosity, while hand-building prioritizes manual manipulation of solid clay body.

Design Flexibility: Slip Casting vs Hand-building Porcelain

Slip casting offers precise replication of intricate designs, making it ideal for producing uniform porcelain pieces with complex shapes, while hand-building porcelain provides greater artistic freedom to create unique, one-of-a-kind forms with varied textures. Designers seeking consistency and detailed patterns often prefer slip casting, whereas those emphasizing individual expression and experimental techniques lean towards hand-building. Both methods influence the final aesthetic, with slip casting favoring uniformity and hand-building showcasing tactile, organic qualities.

Surface Texture and Finish Comparison

Porcelain slip casting produces smooth, uniform surfaces with a fine, consistent texture ideal for detailed, delicate shapes and glossy finishes. Hand-building porcelain results in more varied surface textures, often showcasing subtle fingerprints and tool marks that add a unique, tactile quality to each piece. Slip casting excels in achieving flawless, refined finishes, while hand-building offers a more organic, textured aesthetic that highlights artisanal craftsmanship.

Efficiency and Production Speed

Porcelain slip casting offers significant efficiency advantages over hand-building porcelain due to its ability to produce uniform, complex shapes quickly through automated molds. The production speed of slip casting surpasses hand-building, as multiple pieces can be cast and dried simultaneously, reducing manual labor and time per unit. In contrast, hand-building porcelain requires meticulous shaping and longer drying periods, limiting output and increasing variability in product consistency.

Suitability for Artistic vs Industrial Applications

Porcelain slip casting excels in industrial applications due to its precision, repeatability, and ability to produce intricate shapes consistently, making it ideal for mass production. Hand-building porcelain offers unparalleled artistic flexibility, allowing artists to create unique, expressive forms with texture and variation that cannot be replicated mechanically. The choice between slip casting and hand-building depends on whether the priority is efficiency and uniformity for large-scale production or creative freedom for bespoke, artistic pieces.

Choosing the Right Technique for Your Porcelain Project

Porcelain slip casting offers precision and uniformity ideal for replicating intricate designs, while hand-building porcelain provides greater creative flexibility and unique, artisanal textures. Choosing the right technique depends on your project's scale, desired level of detail, and production speed requirements. For large batches or consistent shapes, slip casting excels; for one-of-a-kind pieces and artistic expression, hand-building is preferable.

Porcelain Slip Casting vs Hand-building Porcelain Infographic

materialdif.com

materialdif.com