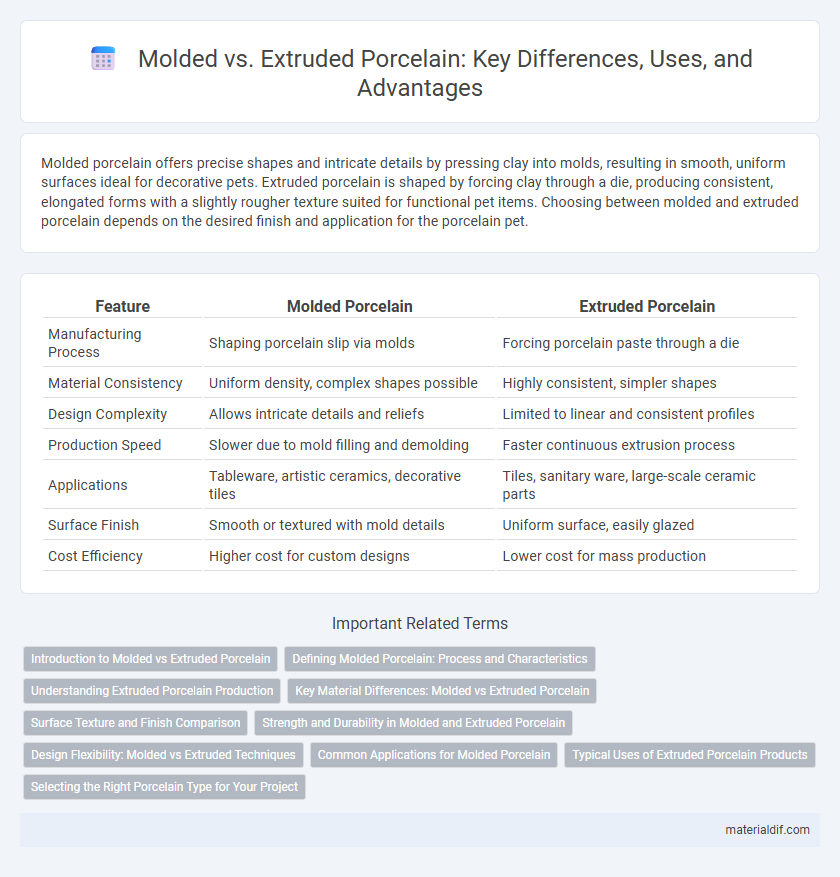

Molded porcelain offers precise shapes and intricate details by pressing clay into molds, resulting in smooth, uniform surfaces ideal for decorative pets. Extruded porcelain is shaped by forcing clay through a die, producing consistent, elongated forms with a slightly rougher texture suited for functional pet items. Choosing between molded and extruded porcelain depends on the desired finish and application for the porcelain pet.

Table of Comparison

| Feature | Molded Porcelain | Extruded Porcelain |

|---|---|---|

| Manufacturing Process | Shaping porcelain slip via molds | Forcing porcelain paste through a die |

| Material Consistency | Uniform density, complex shapes possible | Highly consistent, simpler shapes |

| Design Complexity | Allows intricate details and reliefs | Limited to linear and consistent profiles |

| Production Speed | Slower due to mold filling and demolding | Faster continuous extrusion process |

| Applications | Tableware, artistic ceramics, decorative tiles | Tiles, sanitary ware, large-scale ceramic parts |

| Surface Finish | Smooth or textured with mold details | Uniform surface, easily glazed |

| Cost Efficiency | Higher cost for custom designs | Lower cost for mass production |

Introduction to Molded vs Extruded Porcelain

Molded porcelain is crafted by pressing clay into detailed molds, allowing for precise shapes and intricate designs ideal for decorative and specialized applications. Extruded porcelain is produced by forcing clay through a shaped die, resulting in uniform, continuous profiles commonly used in tiles and architectural elements. Both methods rely on high-temperature kiln firing to achieve porcelain's characteristic strength, density, and translucency.

Defining Molded Porcelain: Process and Characteristics

Molded porcelain is produced by shaping liquid porcelain slip into detailed forms using molds, enabling intricate designs and precise dimensions. This process results in smooth surfaces and consistent thickness, ideal for fine art and functional wares with elaborate patterns. Molded porcelain exhibits high density and translucency due to controlled firing, enhancing its strength and aesthetic appeal compared to extruded porcelain.

Understanding Extruded Porcelain Production

Extruded porcelain production involves forcing a mixture of finely ground clay and other raw materials through a die to create continuous, uniform shapes that are later cut and fired, resulting in dense, durable products with precise dimensions. This method contrasts with molded porcelain, where liquid clay slip is poured into molds to achieve complex designs but may have less structural consistency. Extrusion offers advantages in producing long, consistent profiles such as tiles and pipes, making it ideal for large-scale manufacturing and applications requiring high strength and dimensional accuracy.

Key Material Differences: Molded vs Extruded Porcelain

Molded porcelain is created by pressing liquid clay into complex shapes using molds, resulting in precise, intricate designs with fine details and enhanced surface smoothness. Extruded porcelain is formed by forcing clay through a die to produce uniform, linear shapes like tiles or pipes, offering greater consistency in thickness and density. Key material differences include the density and structural integrity, with molded porcelain often exhibiting higher porosity requiring refined firing processes, while extruded porcelain tends to have a more homogenous microstructure suited for mass production.

Surface Texture and Finish Comparison

Molded porcelain offers a more intricate and varied surface texture due to the shaping process, enabling detailed patterns and smoother finishes ideal for decorative tiles and fine china. Extruded porcelain typically results in a more uniform and consistent surface texture, often with a slightly rougher finish suited for structural and large-format applications. The choice between molded and extruded porcelain largely depends on the desired aesthetic and functional requirements related to surface texture and finish quality.

Strength and Durability in Molded and Extruded Porcelain

Molded porcelain exhibits superior strength due to its dense, uniform microstructure formed under high pressure, enhancing resistance to chipping and cracking. Extruded porcelain, while offering consistent shape and size, typically has a slightly more porous structure, making it less durable under heavy mechanical stress. The controlled molding process results in enhanced durability, making molded porcelain the preferred choice for high-impact applications and long-term wear.

Design Flexibility: Molded vs Extruded Techniques

Molded porcelain offers superior design flexibility by allowing intricate shapes and detailed textures through precise molds, enabling customized and complex forms ideal for decorative applications. Extruded porcelain, produced by forcing clay through a die, is best suited for uniform, linear shapes like tiles and bricks, providing consistency but limited in variation and intricate detail. Choosing between molded and extruded techniques depends on the desired design complexity and application requirements for porcelain products.

Common Applications for Molded Porcelain

Molded porcelain is frequently used in intricate decorative items such as figurines, tableware, and ornamental tiles, where detailed shapes and fine textures are essential. This production method allows for precise control over complex designs, making it ideal for high-quality ceramics found in luxury dinner sets and artistic pottery. In contrast to extruded porcelain, molded porcelain is preferred in applications requiring aesthetic refinement and delicate structural features.

Typical Uses of Extruded Porcelain Products

Extruded porcelain products are commonly used in architectural applications such as cladding panels, wall tiles, and flooring due to their uniform density and durability. These products are ideal for large-scale installations where consistent thickness, precise shapes, and high mechanical strength are required. Extruded porcelain also finds typical use in outdoor paving and industrial settings because of its resistance to abrasion, weather, and chemical exposure.

Selecting the Right Porcelain Type for Your Project

Molded porcelain offers intricate shapes and detailed designs ideal for decorative or complex architectural projects, while extruded porcelain provides uniformity and strength suitable for structural applications like tiles and slabs. Assess the specific requirements of your project such as design complexity, durability, and installation environment to determine the best porcelain type. Choosing between molded and extruded porcelain impacts both aesthetic outcomes and long-term performance in construction or artistic uses.

Molded Porcelain vs Extruded Porcelain Infographic

materialdif.com

materialdif.com