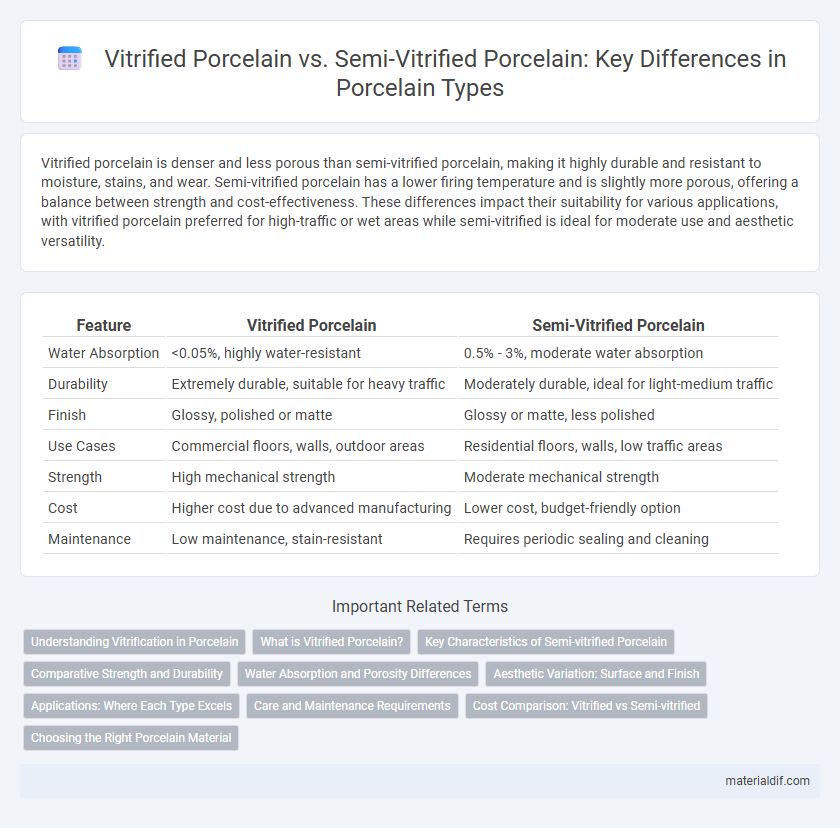

Vitrified porcelain is denser and less porous than semi-vitrified porcelain, making it highly durable and resistant to moisture, stains, and wear. Semi-vitrified porcelain has a lower firing temperature and is slightly more porous, offering a balance between strength and cost-effectiveness. These differences impact their suitability for various applications, with vitrified porcelain preferred for high-traffic or wet areas while semi-vitrified is ideal for moderate use and aesthetic versatility.

Table of Comparison

| Feature | Vitrified Porcelain | Semi-Vitrified Porcelain |

|---|---|---|

| Water Absorption | <0.05%, highly water-resistant | 0.5% - 3%, moderate water absorption |

| Durability | Extremely durable, suitable for heavy traffic | Moderately durable, ideal for light-medium traffic |

| Finish | Glossy, polished or matte | Glossy or matte, less polished |

| Use Cases | Commercial floors, walls, outdoor areas | Residential floors, walls, low traffic areas |

| Strength | High mechanical strength | Moderate mechanical strength |

| Cost | Higher cost due to advanced manufacturing | Lower cost, budget-friendly option |

| Maintenance | Low maintenance, stain-resistant | Requires periodic sealing and cleaning |

Understanding Vitrification in Porcelain

Vitrification in porcelain refers to the process where the material is heated to extremely high temperatures, causing the clay and minerals to fuse and form a dense, glass-like surface. Vitrified porcelain tiles feature low porosity, making them highly resistant to water, stains, and frost, ideal for outdoor and high-traffic areas. Semi-vitrified porcelain tiles undergo partial vitrification, resulting in moderate porosity and durability, suitable for indoor applications where less water resistance is required.

What is Vitrified Porcelain?

Vitrified porcelain is a type of ceramic tile characterized by its low porosity and high density due to vitrification, a process where clay is subjected to intense heat, causing it to fuse into a glass-like, non-porous surface. This makes vitrified porcelain highly resistant to water absorption, staining, and wear, ideal for high-traffic and moisture-prone areas. Its durability and polished finish distinguish it from semi-vitrified porcelain, which has higher porosity and slightly lower strength.

Key Characteristics of Semi-vitrified Porcelain

Semi-vitrified porcelain exhibits moderate porosity and enhanced strength compared to regular ceramics, making it suitable for both indoor and limited outdoor applications. It undergoes partial vitrification during the firing process, resulting in a balanced combination of water absorption rates typically between 0.5% to 3%, and durability. These characteristics provide a cost-effective alternative with good resistance to abrasion, stains, and impact, distinguishing it from fully vitrified porcelain which boasts near-zero porosity.

Comparative Strength and Durability

Vitrified porcelain exhibits superior strength and durability due to its low porosity and dense structure, making it highly resistant to wear and water absorption. Semi-vitrified porcelain has moderate strength and durability, with higher porosity that slightly reduces its resistance to moisture and mechanical stress. The vitrification process enhances the compactness, resulting in longer lifespan and better performance in heavy-duty applications compared to semi-vitrified porcelain.

Water Absorption and Porosity Differences

Vitrified porcelain exhibits a water absorption rate below 0.5%, making it highly dense and resistant to moisture penetration, while semi-vitrified porcelain typically has a higher absorption rate between 3% and 5%, resulting in greater porosity. The lower porosity of vitrified porcelain enhances its durability, stain resistance, and suitability for high-traffic or wet areas. In contrast, semi-vitrified porcelain's increased porosity limits its application to areas with less exposure to water and wear.

Aesthetic Variation: Surface and Finish

Vitrified porcelain exhibits a glass-like, highly polished surface that enhances its aesthetic appeal with a consistent, smooth finish resistant to stains and scratches. Semi-vitrified porcelain offers a less glossy, more matte finish with subtle texture variations, providing a natural stone-like appearance while maintaining moderate durability. The choice between vitrified and semi-vitrified porcelain hinges on desired surface shine and variation in aesthetic expression for interior and exterior design applications.

Applications: Where Each Type Excels

Vitrified porcelain tiles excel in high-traffic commercial spaces and outdoor areas due to their low porosity, high durability, and resistance to stains and moisture. Semi-vitrified porcelain tiles are ideal for residential interiors, including kitchens and bathrooms, where moderate moisture resistance combined with aesthetic variety is essential. Both types optimize durability, but vitrified porcelain's near-zero water absorption makes it superior for rigorous environments.

Care and Maintenance Requirements

Vitrified porcelain requires minimal care and maintenance due to its non-porous surface, which resists stains, moisture, and scratches, making it ideal for high-traffic areas. Semi-vitrified porcelain, while also durable, demands more frequent cleaning and sealing to prevent absorption of liquids and potential staining. Regular wiping with a mild detergent and avoiding abrasive cleaners prolong the lifespan and appearance of both materials.

Cost Comparison: Vitrified vs Semi-vitrified

Vitrified porcelain tiles typically have a higher cost than semi-vitrified tiles due to their denser composition and lower porosity, which enhance durability and stain resistance. Semi-vitrified porcelain offers a more budget-friendly option with reasonable durability, making it suitable for moderate traffic areas. Choosing between vitrified and semi-vitrified porcelain depends on balancing initial investment with long-term performance and maintenance costs.

Choosing the Right Porcelain Material

Vitrified porcelain offers superior strength, low porosity, and high resistance to moisture, making it ideal for heavy-traffic areas and outdoor installations. Semi-vitrified porcelain provides moderate durability and water absorption, suitable for residential spaces where aesthetics and budget balance is essential. Selecting the right porcelain material depends on the specific application requirements, considering factors like durability, water resistance, and cost efficiency.

Vitrified Porcelain vs Semi-vitrified Porcelain Infographic

materialdif.com

materialdif.com