Slip casting uses liquid porcelain slip poured into plaster molds, creating thin, delicate forms ideal for intricate designs and hollow shapes, while press molding involves pressing clay into rigid molds, producing denser, more uniform pieces suitable for heavier, solid items. Slip casting allows for greater detail and precision but requires longer drying times, whereas press molding offers faster production with more structural strength. Choosing between the two methods depends on the desired porcelain item's shape, thickness, and production scale.

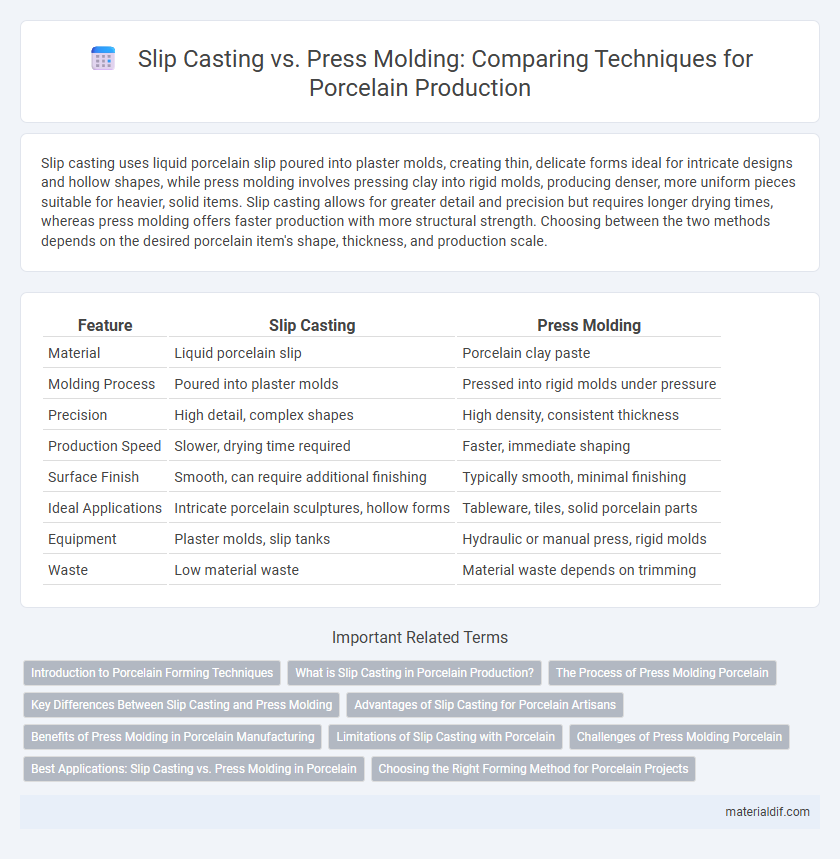

Table of Comparison

| Feature | Slip Casting | Press Molding |

|---|---|---|

| Material | Liquid porcelain slip | Porcelain clay paste |

| Molding Process | Poured into plaster molds | Pressed into rigid molds under pressure |

| Precision | High detail, complex shapes | High density, consistent thickness |

| Production Speed | Slower, drying time required | Faster, immediate shaping |

| Surface Finish | Smooth, can require additional finishing | Typically smooth, minimal finishing |

| Ideal Applications | Intricate porcelain sculptures, hollow forms | Tableware, tiles, solid porcelain parts |

| Equipment | Plaster molds, slip tanks | Hydraulic or manual press, rigid molds |

| Waste | Low material waste | Material waste depends on trimming |

Introduction to Porcelain Forming Techniques

Slip casting and press molding represent two fundamental porcelain forming techniques, each with distinct advantages in shaping ceramic objects. Slip casting utilizes liquid porcelain slip poured into plaster molds, allowing intricate and thin-walled designs, suited for fine details and hollow forms. Press molding involves pressing porcelain clay into rigid molds, offering efficient production of solid, uniform shapes with consistent density and surface texture.

What is Slip Casting in Porcelain Production?

Slip casting in porcelain production involves pouring a liquid clay mixture, known as slip, into a plaster mold that absorbs water, allowing a solid layer of porcelain to form against the mold walls. This technique enables the creation of complex, thin-walled porcelain shapes with fine detail and consistent thickness, making it ideal for artistic and functional pieces. Unlike press molding, slip casting offers greater flexibility in design without the need for high pressure, reducing the risk of defects and allowing for intricate hollow forms.

The Process of Press Molding Porcelain

Press molding porcelain involves pressing a powdered porcelain slip into a pre-formed plaster mold under high pressure, creating a dense, uniform structure with precise detail replication. This method reduces material waste and shortens drying time by compacting the porcelain, resulting in less shrinkage and higher strength after firing. The press molding process is ideal for producing thin-walled, intricate porcelain shapes with consistent thickness and smooth surfaces.

Key Differences Between Slip Casting and Press Molding

Slip casting in porcelain involves pouring liquid clay slip into a plaster mold, allowing for intricate, hollow forms and fine detail control, whereas press molding uses compressed clay pressed into a mold, producing denser, more uniform pieces suited for mass production. Slip casting offers flexibility in shape complexity and is ideal for delicate, thin-walled ceramics, while press molding provides faster cycle times and higher mechanical strength in the final product. These key differences affect texture, production scale, and structural integrity in porcelain manufacturing.

Advantages of Slip Casting for Porcelain Artisans

Slip casting offers porcelain artisans unmatched precision in shaping intricate and delicate forms that press molding cannot easily achieve. The fluid slip allows for seamless layering and fine detail work, enhancing the artistic quality and reducing defects like air bubbles or warping. This method also supports greater versatility in design complexity, fostering unique, custom creations in porcelain art.

Benefits of Press Molding in Porcelain Manufacturing

Press molding in porcelain manufacturing offers superior consistency and precision in producing complex shapes compared to slip casting, reducing material waste and improving surface finish quality. The technique allows for higher production speeds and greater dimensional accuracy, essential for fine porcelain items requiring intricate details. Enhanced durability of molds in press molding also lowers long-term costs and supports large-scale manufacturing efficiency.

Limitations of Slip Casting with Porcelain

Slip casting with porcelain often faces limitations due to slower drying times and higher shrinkage rates, which can result in warping or cracking of delicate shapes. The process struggles with producing sharp edges or thin-walled components compared to press molding, which provides better surface definition and thickness control. Porcelain's fine particle size exacerbates these issues, making slip casting less suitable for intricate or high-precision porcelain products.

Challenges of Press Molding Porcelain

Press molding porcelain presents significant challenges due to the material's fine particle size and high plasticity, which can cause uneven density and warping during drying or firing. Achieving consistent thickness and detail is difficult because porcelain's delicate nature makes it prone to cracking and deformation under the high pressures used in press molding. Moreover, controlling moisture content is critical to prevent defects, requiring precise process adjustments compared to slip casting, which better accommodates porcelain's fluidity.

Best Applications: Slip Casting vs. Press Molding in Porcelain

Slip casting excels in producing complex, hollow porcelain shapes with fine details, making it ideal for intricate art pieces and delicate tableware. Press molding offers superior density and strength, suited for mass-produced, compact porcelain items like plates and tiles. Selecting between slip casting and press molding depends on the desired product's intricacy, durability, and production volume in porcelain manufacturing.

Choosing the Right Forming Method for Porcelain Projects

Slip casting offers precise detail and smooth surfaces by pouring liquid porcelain slip into plaster molds, ideal for complex shapes and fine textures. Press molding compresses damp porcelain clay into rigid molds, providing faster production and denser forms suitable for simpler designs. Selecting between slip casting and press molding depends on project complexity, desired finish, and production volume, ensuring optimal porcelain quality and efficiency.

Slip Casting vs Press Molding (with porcelain) Infographic

materialdif.com

materialdif.com