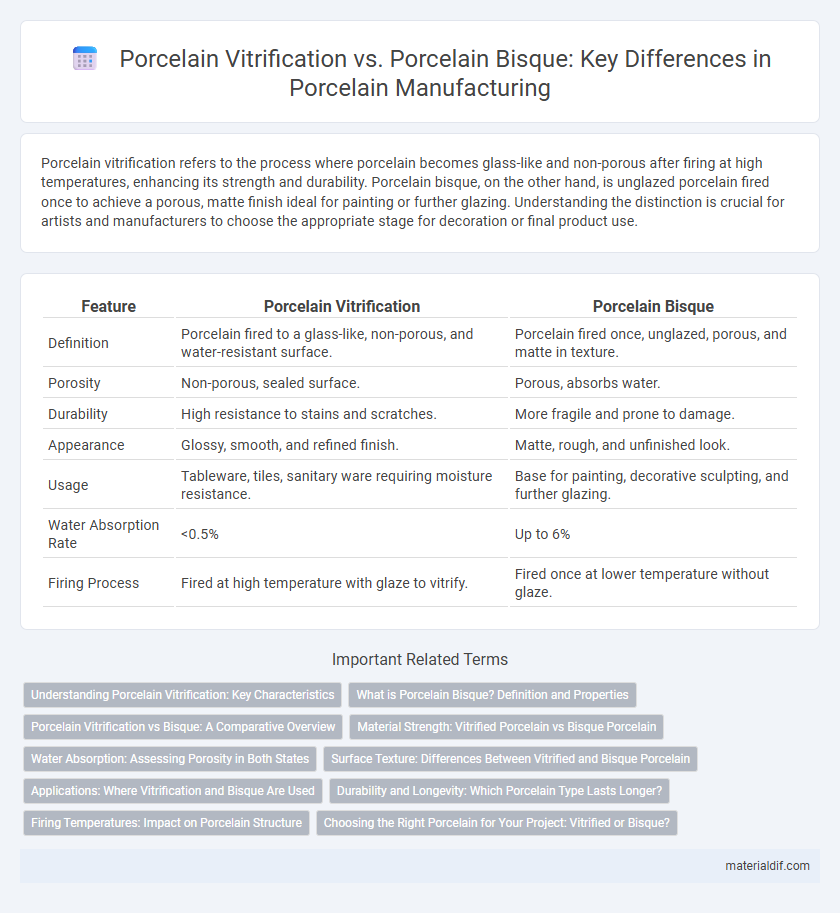

Porcelain vitrification refers to the process where porcelain becomes glass-like and non-porous after firing at high temperatures, enhancing its strength and durability. Porcelain bisque, on the other hand, is unglazed porcelain fired once to achieve a porous, matte finish ideal for painting or further glazing. Understanding the distinction is crucial for artists and manufacturers to choose the appropriate stage for decoration or final product use.

Table of Comparison

| Feature | Porcelain Vitrification | Porcelain Bisque |

|---|---|---|

| Definition | Porcelain fired to a glass-like, non-porous, and water-resistant surface. | Porcelain fired once, unglazed, porous, and matte in texture. |

| Porosity | Non-porous, sealed surface. | Porous, absorbs water. |

| Durability | High resistance to stains and scratches. | More fragile and prone to damage. |

| Appearance | Glossy, smooth, and refined finish. | Matte, rough, and unfinished look. |

| Usage | Tableware, tiles, sanitary ware requiring moisture resistance. | Base for painting, decorative sculpting, and further glazing. |

| Water Absorption Rate | <0.5% | Up to 6% |

| Firing Process | Fired at high temperature with glaze to vitrify. | Fired once at lower temperature without glaze. |

Understanding Porcelain Vitrification: Key Characteristics

Porcelain vitrification refers to the process where the ceramic material becomes glass-like and non-porous after firing, resulting in increased strength, translucency, and water resistance. Unlike porcelain bisque, which remains porous and unglazed after the initial firing, vitrified porcelain achieves a dense, durable structure ideal for functional and decorative uses. This key characteristic enhances the material's longevity and suitability for both artistic and industrial applications.

What is Porcelain Bisque? Definition and Properties

Porcelain bisque refers to unglazed, fired porcelain that exhibits a matte and porous surface, characterized by its chalky white appearance and slight translucency. This material is partially vitrified, meaning it has undergone initial firing to harden but retains some porosity, allowing it to absorb water. Porcelain bisque is prized for its delicate texture and is commonly used in doll making and fine ceramics where a non-glossy finish is desired.

Porcelain Vitrification vs Bisque: A Comparative Overview

Porcelain vitrification is the process where porcelain reaches a glass-like, non-porous state through high-temperature firing, enhancing durability and water resistance. In contrast, porcelain bisque refers to unglazed, partially fired porcelain that retains porosity, making it ideal for painting and decorative purposes. The key difference lies in vitrification producing a sealed, waterproof surface, whereas bisque remains porous and matte.

Material Strength: Vitrified Porcelain vs Bisque Porcelain

Vitrified porcelain exhibits superior material strength due to its dense, non-porous structure formed during high-temperature firing, which enhances durability and resistance to water absorption. Bisque porcelain, in contrast, remains porous because it is only partially fired, resulting in lower mechanical strength and increased susceptibility to chipping and breakage. Consequently, vitrified porcelain is preferred for applications demanding enhanced structural integrity and longevity.

Water Absorption: Assessing Porosity in Both States

Porcelain vitrification significantly reduces water absorption by closing pores and creating a dense, glass-like surface, enhancing its impermeability and strength. In contrast, porcelain bisque retains higher porosity, resulting in increased water absorption due to its unglazed, porous surface. Measuring water absorption in both states provides critical insight into the degree of vitrification and overall durability of the porcelain material.

Surface Texture: Differences Between Vitrified and Bisque Porcelain

Vitrified porcelain undergoes a high-temperature firing process that causes the clay particles to fuse, creating a glass-like, non-porous surface that is smooth and highly durable. Bisque porcelain, fired at a lower temperature, retains a porous, matte surface texture that is more absorbent and less resistant to moisture. The vitrification process significantly enhances the surface hardness and resistance to staining, making vitrified porcelain ideal for high-traffic applications compared to the delicate, unfinished feel of bisque porcelain.

Applications: Where Vitrification and Bisque Are Used

Porcelain vitrification, characterized by its glass-like, non-porous surface, is widely used in applications requiring durability and water resistance, such as dinnerware, tiles, and sanitary ware. Porcelain bisque, being unglazed and porous, is primarily applied in decorative arts, doll making, and sculptural pieces where painting or further finishing is desired. The choice between vitrified and bisque porcelain depends on whether functional resilience or artistic customization is the priority.

Durability and Longevity: Which Porcelain Type Lasts Longer?

Porcelain vitrification results in a denser, glass-like surface that enhances durability and resistance to scratches, stains, and moisture compared to porcelain bisque, which remains porous and more susceptible to damage over time. The vitrified porcelain's low water absorption rate significantly extends its longevity, making it ideal for high-traffic areas and outdoor use. In contrast, bisque porcelain, often unglazed, is more prone to chipping and wear, reducing its lifespan in demanding environments.

Firing Temperatures: Impact on Porcelain Structure

Porcelain vitrification occurs at firing temperatures above 1,200degC, causing the clay body to become glass-like and non-porous, which significantly increases its strength and translucency. In contrast, porcelain bisque is fired at lower temperatures, around 900degC to 1,000degC, leaving the ceramic porous and ideal for subsequent glazing. The firing temperature directly influences the porcelain's structural density, durability, and final finish, with vitrification marking the transition to a fully matured, vitrified ceramic.

Choosing the Right Porcelain for Your Project: Vitrified or Bisque?

Vitrified porcelain offers superior durability and water resistance due to its glass-like fusion during high-temperature firing, making it ideal for high-traffic areas and outdoor installations. Bisque porcelain, characterized by its porous, unglazed surface, provides excellent paint adhesion and detailed hand-finishing options, perfect for artistic or decorative projects. Selecting between vitrified and bisque porcelain depends on your project's functional requirements and aesthetic goals, with vitrified suited for structural strength and bisque preferred for intricate design work.

Porcelain vitrification vs Porcelain bisque Infographic

materialdif.com

materialdif.com