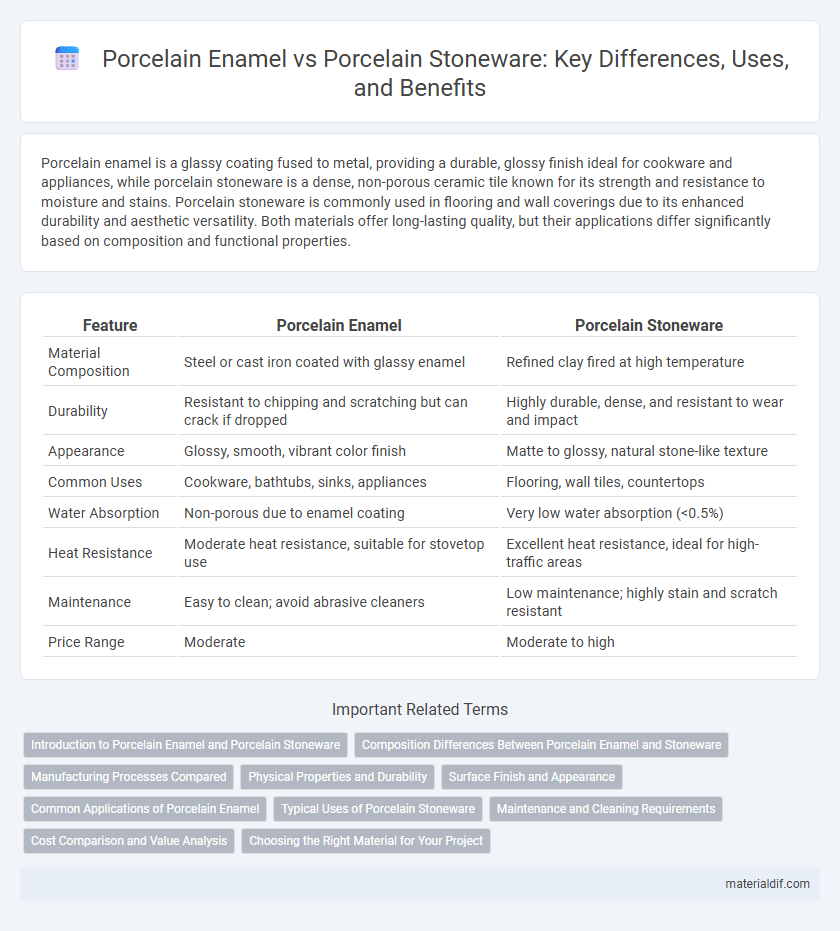

Porcelain enamel is a glassy coating fused to metal, providing a durable, glossy finish ideal for cookware and appliances, while porcelain stoneware is a dense, non-porous ceramic tile known for its strength and resistance to moisture and stains. Porcelain stoneware is commonly used in flooring and wall coverings due to its enhanced durability and aesthetic versatility. Both materials offer long-lasting quality, but their applications differ significantly based on composition and functional properties.

Table of Comparison

| Feature | Porcelain Enamel | Porcelain Stoneware |

|---|---|---|

| Material Composition | Steel or cast iron coated with glassy enamel | Refined clay fired at high temperature |

| Durability | Resistant to chipping and scratching but can crack if dropped | Highly durable, dense, and resistant to wear and impact |

| Appearance | Glossy, smooth, vibrant color finish | Matte to glossy, natural stone-like texture |

| Common Uses | Cookware, bathtubs, sinks, appliances | Flooring, wall tiles, countertops |

| Water Absorption | Non-porous due to enamel coating | Very low water absorption (<0.5%) |

| Heat Resistance | Moderate heat resistance, suitable for stovetop use | Excellent heat resistance, ideal for high-traffic areas |

| Maintenance | Easy to clean; avoid abrasive cleaners | Low maintenance; highly stain and scratch resistant |

| Price Range | Moderate | Moderate to high |

Introduction to Porcelain Enamel and Porcelain Stoneware

Porcelain enamel is a durable coating made by fusing powdered glass to a substrate, typically metal, through high-temperature firing, resulting in a smooth, glass-like surface resistant to corrosion and wear. Porcelain stoneware, on the other hand, is a dense, vitrified ceramic material fired at very high temperatures, known for its strength, low porosity, and suitability for flooring and wall tiles. Both materials share porcelain origins but differ fundamentally in composition, manufacturing processes, and typical applications.

Composition Differences Between Porcelain Enamel and Stoneware

Porcelain enamel consists of a glassy coating fused to a metal base, providing a smooth, durable, and corrosion-resistant surface ideal for cookware and appliances. Porcelain stoneware, however, is a dense, vitrified ceramic made from refined clay and minerals, fired at high temperatures to achieve hardness and low porosity suitable for flooring and wall tiles. The key compositional difference lies in porcelain enamel's use of silica-based frit fused on metal, whereas porcelain stoneware is entirely ceramic with no metallic components.

Manufacturing Processes Compared

Porcelain enamel is created by fusing powdered glass to a metal substrate at high temperatures, resulting in a durable, glossy coating that resists corrosion and wear. Porcelain stoneware is fabricated from finely ground natural clays and feldspar, fired at approximately 1200-1300degC to produce a dense, vitrified, and highly resistant ceramic body. The key manufacturing difference lies in porcelain enamel's glass-metal fusion process versus porcelain stoneware's clay-based sintering, influencing their distinct durability and application properties.

Physical Properties and Durability

Porcelain enamel is a vitreous coating fused to metal substrates, providing a smooth, glossy surface with high resistance to corrosion and thermal shock. Porcelain stoneware, a dense, non-porous ceramic made by firing fine clays at high temperatures, offers superior mechanical strength, low water absorption (below 0.5%), and excellent wear resistance. While porcelain enamel excels in chemical durability and aesthetic finish, porcelain stoneware delivers enhanced physical durability and scratch resistance ideal for flooring and heavy-use surfaces.

Surface Finish and Appearance

Porcelain enamel features a smooth, glossy surface finish created by fusing powdered glass to metal at high temperatures, resulting in a vibrant, reflective appearance that resists scratches and stains. Porcelain stoneware, on the other hand, presents a matte to semi-glossy finish with a dense, non-porous texture that mimics natural stone, offering a more subdued and elegant aesthetic. While porcelain enamel is prized for its bright, polished look, porcelain stoneware excels in durability and subtle surface variation ideal for flooring and wall applications.

Common Applications of Porcelain Enamel

Porcelain enamel is commonly used to coat metal surfaces in cookware, appliances, and architectural panels due to its durable, smooth, and corrosion-resistant finish. It provides excellent heat retention and ease of cleaning, making it ideal for kitchenware like pots, pans, and baking trays. This enamel coating also finds application in bathroom fixtures and outdoor signage, benefiting from its vibrant colors and weather-resistant properties.

Typical Uses of Porcelain Stoneware

Porcelain stoneware is widely utilized in flooring and wall cladding due to its exceptional durability, low water absorption rate, and resistance to wear and stains. Its high mechanical strength makes it ideal for both residential and commercial spaces, including kitchens, bathrooms, shopping centers, and outdoor terraces. This material's versatility and robust properties also make it suitable for high-traffic areas requiring long-lasting performance and easy maintenance.

Maintenance and Cleaning Requirements

Porcelain enamel requires careful maintenance to avoid scratches and chips, and cleaning should be done with non-abrasive, mild detergents to preserve its glossy surface. Porcelain stoneware is more resistant to stains and scratches, allowing for simpler cleaning with standard household cleaners and less frequent maintenance. Both materials benefit from regular wiping to prevent buildup, but porcelain stoneware offers greater durability and ease in long-term upkeep.

Cost Comparison and Value Analysis

Porcelain enamel typically costs less upfront compared to porcelain stoneware, making it attractive for budget-conscious projects, but porcelain stoneware offers greater durability and resistance to wear, providing better long-term value. The initial investment in porcelain stoneware is offset by its low maintenance and longer lifespan, especially in high-traffic or outdoor settings. Analyzing cost per year of use often reveals porcelain stoneware as the more economical choice despite higher initial prices.

Choosing the Right Material for Your Project

Porcelain enamel is a durable coating applied to metal surfaces, offering excellent corrosion resistance and a smooth, glossy finish ideal for cookware and appliances. Porcelain stoneware, made from refined clay fired at high temperatures, provides superior strength, low porosity, and is commonly used for flooring and wall tiles. Selecting the right material depends on project requirements: porcelain enamel suits metal-based applications needing aesthetic protection, while porcelain stoneware excels in structural durability and moisture resistance.

Porcelain Enamel vs Porcelain Stoneware Infographic

materialdif.com

materialdif.com