Kaolin and petuntse are essential components in porcelain production, each contributing unique properties to the final product. Kaolin provides plasticity and whiteness, ensuring the porcelain's structural integrity and smooth texture, while petuntse, a feldspathic rock, acts as a flux that vitrifies during firing, enhancing translucency and hardness. The precise balance between kaolin and petuntse determines the porcelain's strength, durability, and aesthetic qualities.

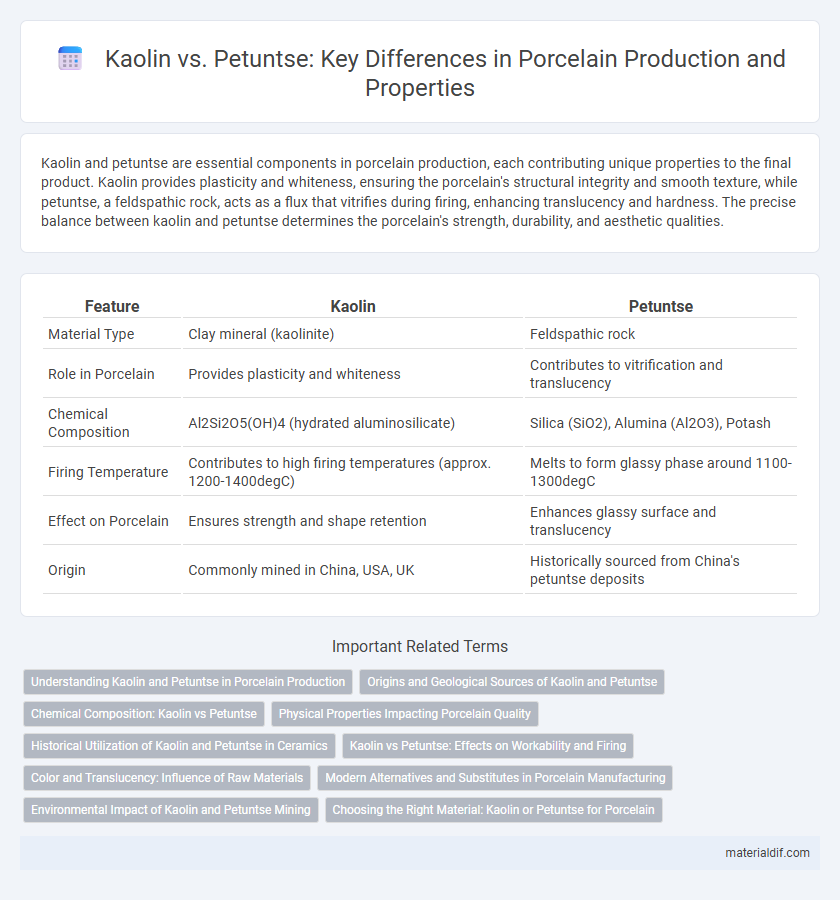

Table of Comparison

| Feature | Kaolin | Petuntse |

|---|---|---|

| Material Type | Clay mineral (kaolinite) | Feldspathic rock |

| Role in Porcelain | Provides plasticity and whiteness | Contributes to vitrification and translucency |

| Chemical Composition | Al2Si2O5(OH)4 (hydrated aluminosilicate) | Silica (SiO2), Alumina (Al2O3), Potash |

| Firing Temperature | Contributes to high firing temperatures (approx. 1200-1400degC) | Melts to form glassy phase around 1100-1300degC |

| Effect on Porcelain | Ensures strength and shape retention | Enhances glassy surface and translucency |

| Origin | Commonly mined in China, USA, UK | Historically sourced from China's petuntse deposits |

Understanding Kaolin and Petuntse in Porcelain Production

Kaolin and petuntse are essential raw materials in porcelain production, with kaolin providing plasticity and whiteness due to its high alumina and silica content, while petuntse contributes vitrification and translucency from its feldspathic composition. The ideal porcelain blend balances about 25-30% kaolin with 70-75% petuntse to achieve the desired strength, durability, and translucency in finished ware. Understanding the differing mineralogical properties of kaolin and petuntse allows manufacturers to control firing temperatures and glaze characteristics for high-quality porcelain.

Origins and Geological Sources of Kaolin and Petuntse

Kaolin is a white clay mineral primarily derived from the chemical weathering of feldspar-rich rocks, predominantly sourced from deposits in regions like Georgia in the USA, Cornwall in the UK, and Jiangxi province in China. Petuntse, or porcelain stone, originates from feldspathic rock formations, mainly found in China's Fujian and Jiangxi provinces, where its unique composition contains feldspar, quartz, and other minerals essential for porcelain production. The contrasting geological sources of kaolin and petuntse contribute to their distinct roles in porcelain manufacture, with kaolin providing plasticity and petuntse contributing to vitrification and translucency.

Chemical Composition: Kaolin vs Petuntse

Kaolin primarily consists of the mineral kaolinite (Al2Si2O5(OH)4), characterized by its high aluminum silicate content and minimal impurities, which provides plasticity and whiteness to porcelain. Petuntse, also known as feldspathic rock, contains a higher proportion of silica (SiO2) and feldspar minerals like orthoclase and albite, contributing to vitrification and translucency during firing. The chemical contrast between kaolin's alumina-rich composition and petuntse's flux-rich silica and alkali metal oxides determines their complementary roles in porcelain production.

Physical Properties Impacting Porcelain Quality

Kaolin, a primary clay mineral with high alumina content, contributes to porcelain's whiteness, plasticity, and resistance to heat, resulting in a durable and smooth texture. Petuntse, a feldspathic rock rich in silica and potassium feldspar, acts as a flux during firing, promoting vitrification and translucency in the porcelain body. The balance between kaolin's refractory properties and petuntse's fluxing characteristics directly impacts the porcelain's strength, translucency, and overall quality.

Historical Utilization of Kaolin and Petuntse in Ceramics

Kaolin, a primary clay mineral, has been historically utilized in porcelain manufacturing for its high purity, whiteness, and plasticity, providing essential workability and strength to the ceramic body. Petuntse, also known as porcelain stone, has traditionally served as the vitrifying component in Chinese porcelain, contributing to translucency and toughness when fired at high temperatures. The combination of kaolin and petuntse was perfected during the Tang and Song dynasties, marking a critical advancement in the development of true hard-paste porcelain.

Kaolin vs Petuntse: Effects on Workability and Firing

Kaolin enhances the workability of porcelain by providing plasticity and strength, allowing for easier shaping and molding. Petuntse contributes to the vitrification process during firing, melting to form a glassy matrix that imparts translucency and durability to the final product. The balance between kaolin and petuntse influences shrinkage, firing temperature, and overall porcelain quality, with kaolin improving structural integrity and petuntse enhancing luster and hardness.

Color and Translucency: Influence of Raw Materials

Kaolin imparts a bright white color and contributes to the high translucency of porcelain, making it ideal for fine, delicate wares. Petuntse, containing impurities like iron, often results in a slightly off-white or grayish hue and reduces translucency due to its denser mineral composition. The balance between kaolin and petuntse in porcelain formulations directly influences the final color purity and light transmission properties.

Modern Alternatives and Substitutes in Porcelain Manufacturing

Modern porcelain manufacturing increasingly relies on synthetic kaolin substitutes and feldspathic materials as alternatives to traditional petuntse, addressing resource scarcity and enhancing material consistency. Engineered kaolin variants provide improved whiteness and plasticity, while advanced feldspar blends mimic the fluxing properties of petuntse, optimizing vitrification and translucency. These innovations enable sustainable production with tailored physical and aesthetic properties, meeting contemporary industry demands.

Environmental Impact of Kaolin and Petuntse Mining

Kaolin mining involves extensive stripping of topsoil and uses significant water resources, leading to habitat disruption and soil erosion. Petuntse extraction, primarily through quarrying, causes landscape alteration and dust pollution but generally requires less water than kaolin mining. Both processes impact local ecosystems, but kaolin mining's higher water consumption and chemical usage present greater environmental challenges.

Choosing the Right Material: Kaolin or Petuntse for Porcelain

Kaolin and petuntse are essential raw materials in porcelain production, with kaolin providing the necessary plasticity and whiteness, while petuntse contributes to vitrification and translucency. Selecting the right material depends on the desired porcelain characteristics: kaolin-rich bodies yield durable, white porcelain, whereas petuntse enhances glassy texture and strength. Balancing the proportions of kaolin and petuntse determines the final porcelain quality, influencing its hardness, translucency, and firing temperature.

Kaolin vs Petuntse Infographic

materialdif.com

materialdif.com