Slip casting offers precise replication of intricate porcelain designs through liquid clay molds, enabling consistent production with minimal material waste. Hand-thrown porcelain on a potter's wheel provides artisans with direct control over shape and texture, creating unique, one-of-a-kind pieces that showcase craftsmanship. While slip casting excels in efficiency and detail, hand-throwing emphasizes individuality and the tactile quality of porcelain art.

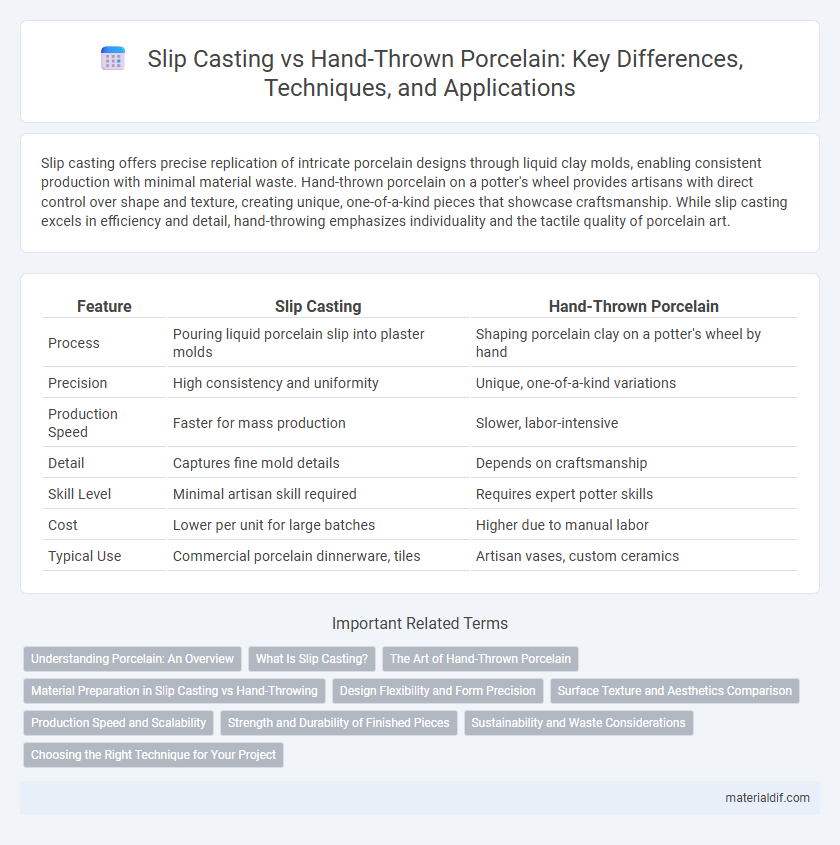

Table of Comparison

| Feature | Slip Casting | Hand-Thrown Porcelain |

|---|---|---|

| Process | Pouring liquid porcelain slip into plaster molds | Shaping porcelain clay on a potter's wheel by hand |

| Precision | High consistency and uniformity | Unique, one-of-a-kind variations |

| Production Speed | Faster for mass production | Slower, labor-intensive |

| Detail | Captures fine mold details | Depends on craftsmanship |

| Skill Level | Minimal artisan skill required | Requires expert potter skills |

| Cost | Lower per unit for large batches | Higher due to manual labor |

| Typical Use | Commercial porcelain dinnerware, tiles | Artisan vases, custom ceramics |

Understanding Porcelain: An Overview

Slip casting offers precise, reproducible porcelain forms by pouring liquid clay into molds, ensuring uniform thickness and detail, ideal for complex shapes and mass production. Hand-thrown porcelain, crafted on a potter's wheel, allows for unique, tactile expressions and organic variations, reflecting the artist's personal touch and skill. Both methods utilize the inherent strength, translucency, and delicate finish of high-quality porcelain but differ significantly in technique and artistic outcome.

What Is Slip Casting?

Slip casting is a ceramic forming technique where liquid clay, known as slip, is poured into a plaster mold to create detailed and uniform porcelain shapes. This method allows for precise replication of complex designs and is ideal for mass production compared to hand-thrown porcelain, which involves shaping clay manually on a potter's wheel. The porous plaster absorbs water from the slip, causing it to solidify and form a sturdy porcelain shell inside the mold.

The Art of Hand-Thrown Porcelain

Hand-thrown porcelain showcases an artisanal mastery where each piece is uniquely shaped on a potter's wheel, highlighting the craftsman's skill and individual expression. Unlike slip casting, which uses molds for uniformity, hand-thrown porcelain allows for textural variations and organic forms that emphasize the tactile qualities of fine-grained porcelain clay. This technique requires precise control of wheel speed, porcelain body moisture, and shaping tools to create delicate yet durable vessels prized in both functional and decorative ceramic art.

Material Preparation in Slip Casting vs Hand-Throwing

Slip casting involves preparing a liquid clay mixture called slip by finely grinding raw porcelain clay and suspending it in water to achieve a smooth, pourable consistency essential for mold filling. In hand-throwing porcelain, the clay is kneaded and wedged to remove air bubbles and ensure uniform plasticity, allowing for precise shaping on the potter's wheel. The slip casting method emphasizes fluidity and suspension, while hand-throwing prioritizes plasticity and structural integrity during material preparation.

Design Flexibility and Form Precision

Slip casting offers superior design flexibility by allowing intricate molds to produce complex and consistent porcelain shapes, making it ideal for detailed patterns and repeatable forms. Hand-thrown porcelain provides unique form precision through skilled craftsmanship, enabling subtle variations and organic shapes that showcase the artisan's touch. Both techniques balance precision and creativity, with slip casting excelling in uniformity and hand-throwing highlighting personalized design nuances.

Surface Texture and Aesthetics Comparison

Slip casting produces porcelain with a consistently smooth and uniform surface texture, ideal for intricate shapes and fine details due to the liquid clay settling evenly in molds. Hand-thrown porcelain reveals a more tactile and organic surface, characterized by subtle ridges and variations created by the potter's fingers and tools, enhancing its unique aesthetic and artisanal appeal. Both methods offer distinct textures: slip casting emphasizes precision and sleekness, while hand-throwing highlights individuality and handcrafted beauty.

Production Speed and Scalability

Slip casting offers faster production speed and higher scalability compared to hand-thrown porcelain, enabling large quantities of identical pieces with minimal labor. Hand-thrown porcelain requires skilled artisans, resulting in slower output and limited scalability due to the individual craftsmanship process. Industrial manufacturers favor slip casting for mass production efficiency, while hand-throwing remains valuable for artisanal, unique creations.

Strength and Durability of Finished Pieces

Slip casting produces porcelain pieces with consistent density and fewer air pockets, resulting in superior strength and durability compared to hand-thrown porcelain, which may have slight variations in thickness and structural integrity. The controlled environment of slip casting minimizes defects and enhances the finished piece's resistance to chipping and cracking. Although hand-thrown porcelain offers artistic uniqueness, slip casting's precision contributes to enhanced mechanical properties ideal for functional and decorative objects.

Sustainability and Waste Considerations

Slip casting generates minimal waste by recycling excess slip, making it a sustainable method for porcelain production with consistent material use. Hand-thrown porcelain often results in greater material loss due to trimming and shaping processes, contributing to increased waste. Efficient slip recovery systems and controlled slip formulations enhance sustainability in slip casting compared to traditional hand-throwing techniques.

Choosing the Right Technique for Your Project

Slip casting offers precise, repeatable shapes ideal for complex or mass-produced porcelain items, making it perfect for projects requiring uniformity and intricate details. Hand-thrown porcelain allows greater artistic expression and unique, organic forms, suitable for bespoke pieces where individual character and craftsmanship are prioritized. Selecting between slip casting and hand-throwing depends on desired design complexity, production scale, and the balance between consistency and artistic uniqueness.

Slip casting vs Hand-thrown porcelain Infographic

materialdif.com

materialdif.com