High-fire porcelain is fired at temperatures above 2300degF, resulting in a highly vitrified, durable, and translucent final product ideal for fine dinnerware and artistic pieces. Mid-fire porcelain, fired between 2100degF and 2300degF, offers a balance of strength and color variety, making it versatile for both functional ware and decorative ceramics. The higher firing temperature of high-fire porcelain enhances its resistance to chipping and thermal shock compared to mid-fire porcelain.

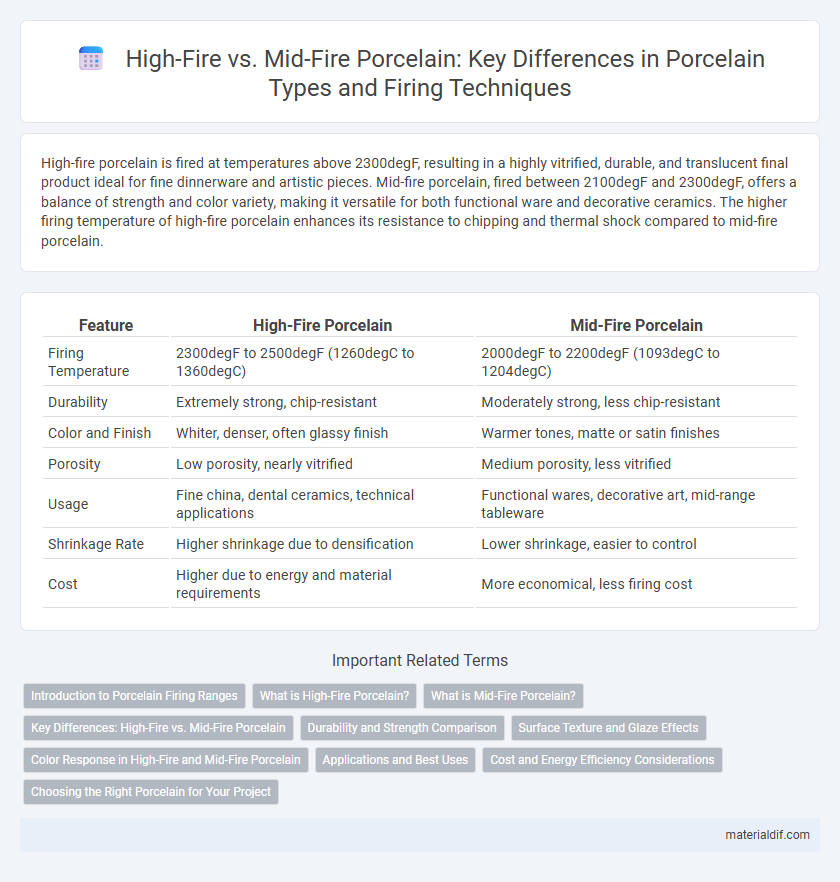

Table of Comparison

| Feature | High-Fire Porcelain | Mid-Fire Porcelain |

|---|---|---|

| Firing Temperature | 2300degF to 2500degF (1260degC to 1360degC) | 2000degF to 2200degF (1093degC to 1204degC) |

| Durability | Extremely strong, chip-resistant | Moderately strong, less chip-resistant |

| Color and Finish | Whiter, denser, often glassy finish | Warmer tones, matte or satin finishes |

| Porosity | Low porosity, nearly vitrified | Medium porosity, less vitrified |

| Usage | Fine china, dental ceramics, technical applications | Functional wares, decorative art, mid-range tableware |

| Shrinkage Rate | Higher shrinkage due to densification | Lower shrinkage, easier to control |

| Cost | Higher due to energy and material requirements | More economical, less firing cost |

Introduction to Porcelain Firing Ranges

High-fire porcelain is typically fired at temperatures between 1,200degC and 1,450degC, resulting in a dense, vitrified body with enhanced durability and translucency. Mid-fire porcelain, fired at slightly lower temperatures ranging from 1,100degC to 1,250degC, offers a balance between strength and surface texture, often preserving more color vibrancy in glazes. Understanding these firing ranges is essential for artists and manufacturers to achieve desired aesthetic and functional properties in porcelain ceramics.

What is High-Fire Porcelain?

High-fire porcelain is a type of ceramic fired at temperatures between 2,300degF and 2,600degF (1,260degC to 1,430degC), resulting in a dense, non-porous, and highly durable material. This firing process enhances the strength and resistance to chipping compared to mid-fire porcelain, which is typically fired at lower temperatures ranging from 1,820degF to 2,190degF (995degC to 1,200degC). High-fire porcelain's vitrification creates a smooth, glass-like surface ideal for fine ceramics and tableware demanding both aesthetic appeal and longevity.

What is Mid-Fire Porcelain?

Mid-fire porcelain is a type of ceramic fired at temperatures between 1,100degC and 1,250degC (2,012degF to 2,282degF), offering a balance between durability and color vibrancy. It features a slightly more porous body than high-fire porcelain, making it ideal for detailed glaze effects and a wider color palette. Because mid-fire porcelain combines strength with aesthetic versatility, it is favored in both functional ware and decorative ceramics.

Key Differences: High-Fire vs. Mid-Fire Porcelain

High-fire porcelain is fired at temperatures above 2300degF (1260degC), resulting in a denser, more vitrified body with enhanced durability and translucency, while mid-fire porcelain is fired between 2100degF and 2300degF (1150degC-1260degC), producing a slightly porous but more thermally stable ceramic. High-fire porcelain typically exhibits a whiter, smoother surface ideal for fine china and sculpture, whereas mid-fire porcelain offers greater flexibility for glaze variety and is favored for tableware and decorative pieces. The key differences lie in firing temperature impacts on strength, surface texture, and glaze compatibility, influencing the final ceramic's functional and aesthetic properties.

Durability and Strength Comparison

High-fire porcelain, typically fired at temperatures above 2300degF (1260degC), exhibits greater durability and strength due to its denser vitrification process, resulting in enhanced chip resistance and hardness. Mid-fire porcelain, fired between 2100degF and 2300degF (1150degC to 1260degC), offers a balance of strength and aesthetic flexibility but generally has lower mechanical strength and is more prone to minor chipping under heavy use. The higher firing temperature in high-fire porcelain creates a more robust molecular structure, making it ideal for applications requiring superior wear resistance and long-lasting performance.

Surface Texture and Glaze Effects

High-fire porcelain, typically fired between 2300degF and 2460degF, features a dense, vitrified surface with a smooth texture and a glossy glaze effect due to complete melting of the glaze materials. Mid-fire porcelain, fired around 2167degF to 2264degF, exhibits a slightly softer texture with greater variation in surface effects, allowing for more matte and satin glazes that showcase nuanced color depth. The higher firing temperature of high-fire porcelain enhances durability and creates a glass-like finish, while mid-fire porcelain offers increased versatility in glaze chemistry and artistic surface textures.

Color Response in High-Fire and Mid-Fire Porcelain

High-fire porcelain typically exhibits a more subdued and natural color response due to its higher firing temperature, which ranges from 2300degF to 2500degF, causing glazes to mature and colors to deepen with subtle variations. Mid-fire porcelain, fired between 2100degF and 2300degF, allows for a broader and brighter color palette, with glazes often displaying more vivid and consistent hues. The difference in firing temperature directly impacts the glaze chemistry and final color saturation, with mid-fire porcelain being preferred for projects requiring vibrant and precise color control.

Applications and Best Uses

High-fire porcelain, typically fired at temperatures above 2300degF (1260degC), is ideal for durable dinnerware, tile, and sanitaryware due to its strength and vitrification. Mid-fire porcelain, fired between 2150degF and 2300degF (1175degC - 1260degC), offers a balance of strength and color versatility, making it suitable for decorative objects and art ceramics. Use high-fire porcelain for functional, everyday items requiring toughness, while mid-fire is best for detailed glazing and creative expression.

Cost and Energy Efficiency Considerations

High-fire porcelain typically requires firing temperatures above 2300degF (1260degC), resulting in higher energy consumption and increased costs compared to mid-fire porcelain, which fires between 2150degF and 2260degF (1175degC to 1235degC). The elevated firing temperatures of high-fire porcelain contribute to greater durability and a denser, more vitrified body, justifying the additional expense for high-end applications. Mid-fire porcelain offers a more energy-efficient production process with lower kiln wear, making it a cost-effective choice for large-scale manufacturing without significantly compromising strength or translucency.

Choosing the Right Porcelain for Your Project

High-fire porcelain, fired at temperatures above 2300degF, offers superior durability and a more vitrified, glass-like surface ideal for functional ware requiring strength and resistance to chipping. Mid-fire porcelain, fired between 2100degF and 2300degF, provides a balance between durability and color vibrancy, often preferred for decorative pieces and detailed glaze work. Selecting the right porcelain depends on project needs, where high-fire suits utilitarian items exposed to heavy use, and mid-fire supports artistic expression with a broader palette and moderate durability.

High-fire porcelain vs Mid-fire porcelain Infographic

materialdif.com

materialdif.com