High-fired porcelain is fired at temperatures above 2300degF, resulting in a denser, harder, and more durable ceramic with a translucent, glass-like quality. Low-fired porcelain, fired below 2100degF, tends to be more porous and softer, offering brighter colors but less strength and chip resistance. The firing temperature significantly impacts the porcelain's texture, durability, and aesthetic properties, influencing its suitability for various functional or decorative uses.

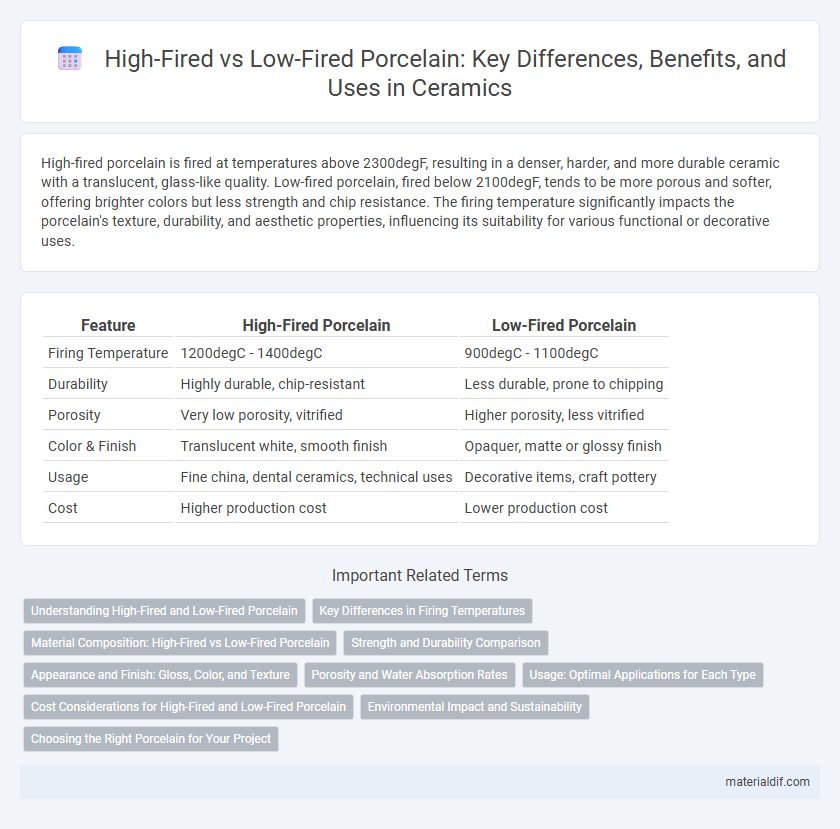

Table of Comparison

| Feature | High-Fired Porcelain | Low-Fired Porcelain |

|---|---|---|

| Firing Temperature | 1200degC - 1400degC | 900degC - 1100degC |

| Durability | Highly durable, chip-resistant | Less durable, prone to chipping |

| Porosity | Very low porosity, vitrified | Higher porosity, less vitrified |

| Color & Finish | Translucent white, smooth finish | Opaquer, matte or glossy finish |

| Usage | Fine china, dental ceramics, technical uses | Decorative items, craft pottery |

| Cost | Higher production cost | Lower production cost |

Understanding High-Fired and Low-Fired Porcelain

High-fired porcelain is typically fired at temperatures above 1,200degC (2,192degF), resulting in a dense, vitrified, and durable material with a smooth, glass-like surface and high resistance to chipping and thermal shock. Low-fired porcelain, fired at temperatures below 1,200degC (2,192degF), is more porous and less durable but allows for a wider range of vibrant glaze colors and surface textures. Understanding the firing temperature impact is crucial for selecting porcelain that balances strength, translucency, and aesthetic qualities for specific ceramic applications.

Key Differences in Firing Temperatures

High-fired porcelain is typically fired at temperatures between 1,200degC and 1,400degC, resulting in a denser, more vitrified body with enhanced strength and durability. Low-fired porcelain, fired at temperatures around 1,000degC to 1,100degC, tends to be more porous and less durable but allows for a wider variety of glazes and surface textures. The key difference in firing temperatures directly impacts the porcelain's physical properties, translucency, and resistance to chipping.

Material Composition: High-Fired vs Low-Fired Porcelain

High-fired porcelain is composed of kaolin, feldspar, and quartz fired at temperatures typically between 1,200degC and 1,400degC, resulting in a vitrified, dense, and durable material. Low-fired porcelain contains a higher percentage of clay and fluxes, such as feldspar and bone ash, fired at lower temperatures around 900degC to 1,100degC, which produces a more porous and less vitrified body. The difference in material composition and firing temperature directly affects the porcelain's strength, translucency, and resistance to water absorption.

Strength and Durability Comparison

High-fired porcelain is vitrified at temperatures above 1,200degC, resulting in a dense, glass-like structure that offers superior strength and exceptional durability, making it highly resistant to chipping and thermal shock. Low-fired porcelain, fired below 1,200degC, is more porous and less robust, leading to increased vulnerability to cracks and wear over time. The enhanced mechanical properties of high-fired porcelain make it the preferred choice for heavy-use applications requiring long-term resilience.

Appearance and Finish: Gloss, Color, and Texture

High-fired porcelain typically exhibits a smooth, glossy finish with rich, deep colors resulting from firing temperatures above 1200degC, enhancing vitrification and durability. Low-fired porcelain, fired between 950degC and 1100degC, often features a softer matte or semi-gloss surface with lighter, more pastel hues and a slightly porous texture. The higher firing temperature in high-fired porcelain produces a denser, more translucent body, while low-fired porcelain maintains greater porosity and a more delicate, hand-crafted appearance.

Porosity and Water Absorption Rates

High-fired porcelain is characterized by a firing temperature above 1,200degC, resulting in a dense, vitrified body with low porosity and water absorption rates typically below 0.5%. Low-fired porcelain, fired between 1,000degC and 1,200degC, exhibits higher porosity and water absorption rates ranging from 1% to 5%, making it less durable and more susceptible to moisture penetration. The reduced porosity in high-fired porcelain enhances its strength, translucency, and resistance to staining, ideal for fine dinnerware and high-end applications.

Usage: Optimal Applications for Each Type

High-fired porcelain, vitrified at temperatures above 1200degC, exhibits superior strength and durability, making it ideal for functional items like dinnerware, tiles, and sanitary ware that require resistance to wear and thermal shock. Low-fired porcelain, fired between 900degC and 1100degC, retains greater porosity and translucency, which suits decorative objects, fine art pieces, and detailed figurines where intricate surface detail and color vibrancy are essential. Selecting the appropriate firing range ensures optimal performance and aesthetic qualities tailored to specific ceramic applications.

Cost Considerations for High-Fired and Low-Fired Porcelain

High-fired porcelain typically incurs higher production costs due to the extended kiln time and increased energy consumption required to reach temperatures between 1,200degC and 1,450degC. Low-fired porcelain, fired at temperatures around 1,000degC to 1,200degC, offers cost savings with shorter kiln cycles and reduced energy use but can result in less durability and increased porosity. Manufacturers balance these cost considerations against desired attributes such as strength, translucency, and finish quality when selecting firing methods.

Environmental Impact and Sustainability

High-fired porcelain, typically fired at temperatures above 1,200degC, results in a denser, more durable product with lower porosity, which extends its lifecycle and reduces waste, promoting sustainability. Low-fired porcelain, fired below 1,200degC, consumes less energy during production but often requires glazes containing lead or other harmful substances, posing environmental risks. Choosing high-fired porcelain reduces environmental impact through longevity and non-toxic finishes, aligning with eco-friendly manufacturing practices.

Choosing the Right Porcelain for Your Project

High-fired porcelain, typically fired at temperatures above 2300degF (1260degC), offers superior strength, translucency, and durability, making it ideal for fine dinnerware and artistic sculptures. Low-fired porcelain, fired at temperatures around 2000-2100degF (1093-1149degC), provides greater color range and surface texture options but with less mechanical strength, suited for decorative items and experimental works. Selecting the right porcelain depends on the project's functional requirements, desired aesthetic qualities, and firing capabilities available.

High-Fired Porcelain vs Low-Fired Porcelain Infographic

materialdif.com

materialdif.com