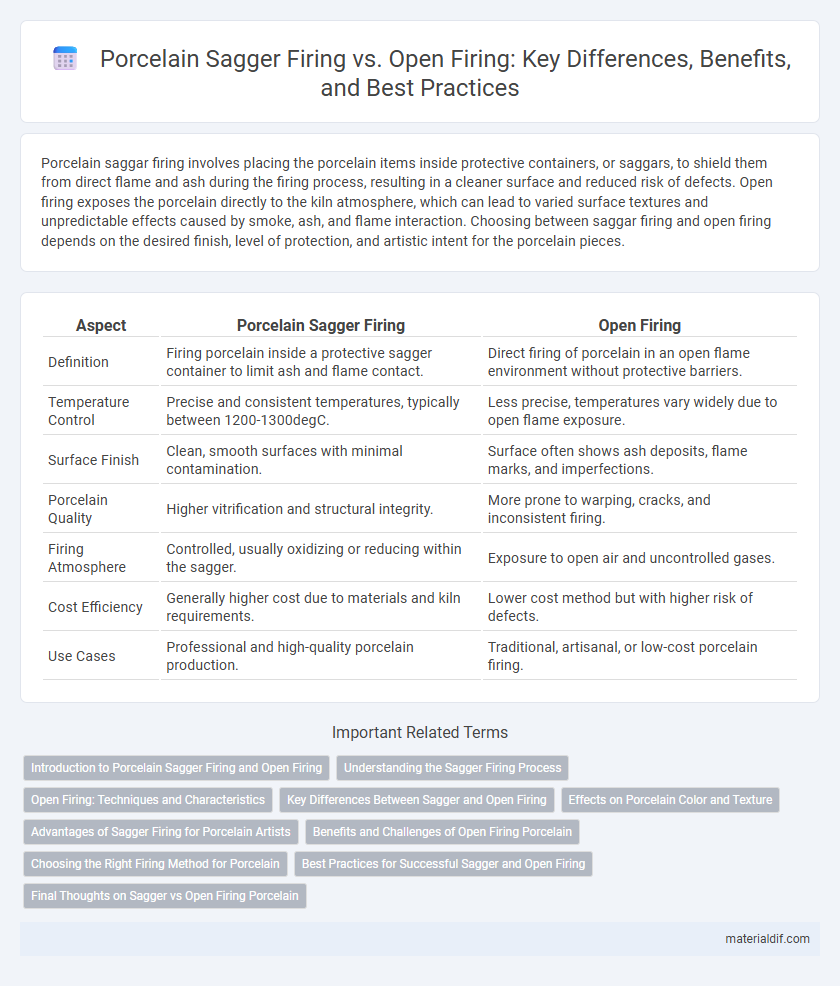

Porcelain saggar firing involves placing the porcelain items inside protective containers, or saggars, to shield them from direct flame and ash during the firing process, resulting in a cleaner surface and reduced risk of defects. Open firing exposes the porcelain directly to the kiln atmosphere, which can lead to varied surface textures and unpredictable effects caused by smoke, ash, and flame interaction. Choosing between saggar firing and open firing depends on the desired finish, level of protection, and artistic intent for the porcelain pieces.

Table of Comparison

| Aspect | Porcelain Sagger Firing | Open Firing |

|---|---|---|

| Definition | Firing porcelain inside a protective sagger container to limit ash and flame contact. | Direct firing of porcelain in an open flame environment without protective barriers. |

| Temperature Control | Precise and consistent temperatures, typically between 1200-1300degC. | Less precise, temperatures vary widely due to open flame exposure. |

| Surface Finish | Clean, smooth surfaces with minimal contamination. | Surface often shows ash deposits, flame marks, and imperfections. |

| Porcelain Quality | Higher vitrification and structural integrity. | More prone to warping, cracks, and inconsistent firing. |

| Firing Atmosphere | Controlled, usually oxidizing or reducing within the sagger. | Exposure to open air and uncontrolled gases. |

| Cost Efficiency | Generally higher cost due to materials and kiln requirements. | Lower cost method but with higher risk of defects. |

| Use Cases | Professional and high-quality porcelain production. | Traditional, artisanal, or low-cost porcelain firing. |

Introduction to Porcelain Sagger Firing and Open Firing

Porcelain sagger firing involves placing ceramic pieces inside protective containers called saggers that shield the work from direct flame and ash, resulting in controlled atmospheres and refined surface qualities. Open firing exposes porcelain directly to flames and combustion gases, often producing unpredictable textures and color variations due to uneven heat distribution and ash interaction. Understanding these methods is essential for achieving desired aesthetic effects and functional properties in porcelain ceramics.

Understanding the Sagger Firing Process

Porcelain sagger firing involves enclosing the ceramic pieces in a protective container called a sagger, which shields them from direct flame and ash, ensuring controlled firing atmospheres that enhance surface quality and reduce defects. This process maintains consistent kiln temperatures and limits oxidation, resulting in improved glaze finish and structural integrity compared to open firing, where porcelain is exposed directly to flames and potential contaminants. Mastery of sagger firing parameters, such as temperature ramps and atmosphere control, is crucial for achieving high-quality porcelain with superior mechanical and aesthetic properties.

Open Firing: Techniques and Characteristics

Open firing porcelain involves directly exposing the ware to flames and smoke, creating unique surface effects such as smoky textures and unpredictable color variations. Techniques include pit firing, where porcelain pieces are placed in combustible materials like wood or sawdust, and barrel firing, which uses metal containers to control the atmosphere and protect the pieces. This method produces organic, rustic finishes but requires careful temperature management to prevent warping or cracking due to uneven heat distribution.

Key Differences Between Sagger and Open Firing

Porcelain sagger firing involves placing ceramic pieces inside protective containers called saggers that shield them from direct flame and debris, resulting in more controlled atmospheres and reduced surface imperfections. Open firing exposes porcelain directly to furnace flames and atmospheric elements, often leading to uneven heat distribution and greater risk of contamination or glaze defects. The key difference lies in surface quality and firing consistency, with sagger firing providing enhanced protection for delicate glazes compared to the variable conditions of open firing.

Effects on Porcelain Color and Texture

Porcelain sagger firing produces a controlled atmosphere that enhances the clay body's color vibrancy and results in a smoother, more refined texture by protecting the piece from direct flame and ash contact. Open firing exposes porcelain to unpredictable flames and ash, causing varied surface effects, including darker spots and rougher textures due to uneven heat distribution and sulfur deposits. The choice between sagger and open firing significantly impacts the final appearance, with sagger firing favoring consistent coloration and texture, while open firing creates unique, rustic finishes.

Advantages of Sagger Firing for Porcelain Artists

Sagger firing offers porcelain artists enhanced protection against direct flame and ash, resulting in cleaner surfaces and richer color retention compared to open firing. This method controls atmosphere and temperature more precisely, reducing defects such as warping or blistering in delicate porcelain pieces. Furthermore, sagger firing enables complex glaze effects and textures by isolating porcelain within the container, expanding creative possibilities for artists.

Benefits and Challenges of Open Firing Porcelain

Open firing porcelain offers unique artistic expression through direct flame and ash effects, creating unpredictable surface textures and natural variations prized by ceramic artists. However, this method presents challenges including the risk of warping or cracking due to uneven heat exposure and increased susceptibility to contamination from ash and debris. Despite these risks, open firing can result in durable, weather-resistant ceramics with a distinctive rustic aesthetic unattainable in controlled kiln environments.

Choosing the Right Firing Method for Porcelain

Porcelain sagger firing offers enhanced protection from ash and flame, ensuring a smoother surface finish and reducing defects like warping or blistering compared to open firing. Open firing exposes porcelain directly to heat and atmospheric elements, which can create unique textures but increases the risk of uneven firing and surface impurities. Selecting the appropriate firing method depends on the desired aesthetic outcome, durability requirements, and control over the firing atmosphere.

Best Practices for Successful Sagger and Open Firing

Porcelain sagger firing requires using a high-quality refractory container to protect delicate pieces from direct flame and ash, ensuring uniform heat distribution and preventing warping or blemishes. Open firing demands careful temperature control and placement to avoid thermal shock and uneven firing, often involving gradual heating and cooling cycles for optimal results. Both methods benefit from proper kiln atmosphere management and consistent monitoring to achieve flawless porcelain finishes.

Final Thoughts on Sagger vs Open Firing Porcelain

Sagger firing porcelain offers superior protection from direct flame and ash, resulting in a cleaner and more controlled final surface compared to open firing. Open firing exposes porcelain to atmospheric elements, often causing unpredictable textures and color variations due to ash deposits and uneven heat distribution. Choosing sagger firing enhances the durability and aesthetic precision of porcelain pieces, ideal for artists seeking refined and consistent finishes.

Porcelain Sagger Firing vs Open Firing Infographic

materialdif.com

materialdif.com