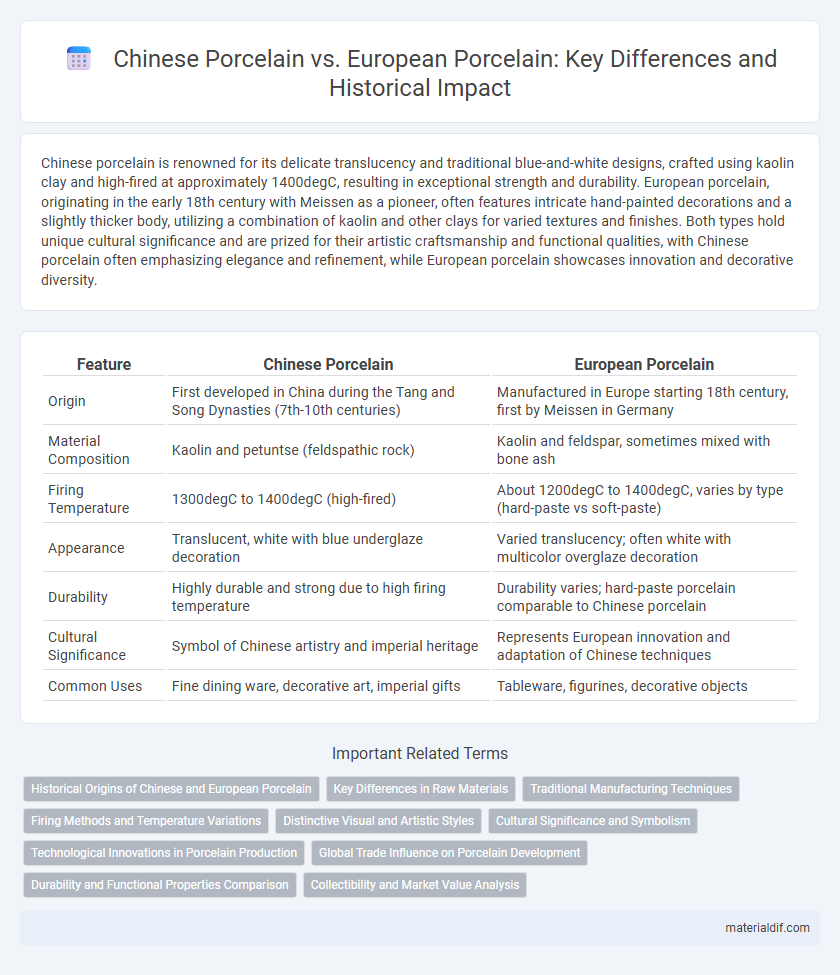

Chinese porcelain is renowned for its delicate translucency and traditional blue-and-white designs, crafted using kaolin clay and high-fired at approximately 1400degC, resulting in exceptional strength and durability. European porcelain, originating in the early 18th century with Meissen as a pioneer, often features intricate hand-painted decorations and a slightly thicker body, utilizing a combination of kaolin and other clays for varied textures and finishes. Both types hold unique cultural significance and are prized for their artistic craftsmanship and functional qualities, with Chinese porcelain often emphasizing elegance and refinement, while European porcelain showcases innovation and decorative diversity.

Table of Comparison

| Feature | Chinese Porcelain | European Porcelain |

|---|---|---|

| Origin | First developed in China during the Tang and Song Dynasties (7th-10th centuries) | Manufactured in Europe starting 18th century, first by Meissen in Germany |

| Material Composition | Kaolin and petuntse (feldspathic rock) | Kaolin and feldspar, sometimes mixed with bone ash |

| Firing Temperature | 1300degC to 1400degC (high-fired) | About 1200degC to 1400degC, varies by type (hard-paste vs soft-paste) |

| Appearance | Translucent, white with blue underglaze decoration | Varied translucency; often white with multicolor overglaze decoration |

| Durability | Highly durable and strong due to high firing temperature | Durability varies; hard-paste porcelain comparable to Chinese porcelain |

| Cultural Significance | Symbol of Chinese artistry and imperial heritage | Represents European innovation and adaptation of Chinese techniques |

| Common Uses | Fine dining ware, decorative art, imperial gifts | Tableware, figurines, decorative objects |

Historical Origins of Chinese and European Porcelain

Chinese porcelain originated during the Tang Dynasty (618-907 AD), reaching its peak in the Song (960-1279 AD) and Ming (1368-1644 AD) Dynasties, known for its kaolin clay and high-temperature firing methods producing translucent, durable ceramics. European porcelain began in the early 18th century with the Meissen manufactory in Germany (1710), following centuries of importing expensive Chinese porcelain; it utilized different raw materials like white-firing clays and introduced hard-paste and soft-paste varieties. The distinct historical timelines reflect the technological advancements and cultural exchanges that influenced porcelain production across continents.

Key Differences in Raw Materials

Chinese porcelain primarily utilizes kaolin clay combined with petuntse, a feldspathic rock, enabling high firing temperatures that produce a translucent, white ceramic body. European porcelain often incorporates a mixture of kaolin and feldspar but tends to contain higher levels of bone ash in bone china varieties, resulting in increased strength and a slightly different translucency. The distinct raw material compositions influence the porcelain's texture, durability, and firing temperature requirements, marking clear differences between Chinese and European porcelain traditions.

Traditional Manufacturing Techniques

Chinese porcelain features a high-fired kaolin and petuntse composition, producing a translucent, delicate body through centuries-old wheel-throwing and hand-painting techniques. European porcelain, originating in 18th-century Meissen, employs a hard-paste formula combining kaolin and feldspar, integrating kiln-firing innovations and mold casting to achieve durability and detailed shapes. Traditional manufacturing in both regions emphasizes intricate glazing methods and multiple firing stages, ensuring the iconic strength and aesthetic that define authentic porcelain.

Firing Methods and Temperature Variations

Chinese porcelain is traditionally fired at temperatures ranging from 1,200 to 1,400 degrees Celsius using wood or coal kilns, resulting in a highly vitrified and translucent finish. European porcelain, often produced in electric or gas kilns, typically fires at slightly lower temperatures around 1,200 to 1,300 degrees Celsius, emphasizing durability and whiteness. These differences in firing methods and temperature variations directly influence the texture, strength, and translucency of the final porcelain products.

Distinctive Visual and Artistic Styles

Chinese porcelain is renowned for its delicate blue-and-white patterns, intricate brushwork, and traditional motifs inspired by nature and mythology, reflecting centuries of refined craftsmanship. European porcelain, particularly Meissen and Sevres, showcases elaborate Rococo and Baroque designs with a focus on ornate gilding, vibrant polychrome colors, and sculptural forms influenced by Western artistic movements. The distinct firing techniques and raw materials used in each region result in unique translucency and surface finishes that underscore their cultural artistic identities.

Cultural Significance and Symbolism

Chinese porcelain, renowned for its intricate blue-and-white designs, embodies centuries of cultural symbolism emphasizing harmony, prosperity, and spiritual balance rooted in Confucian values. European porcelain, particularly Meissen and Sevres, reflects Renaissance and Enlightenment ideals, symbolizing wealth, sophistication, and the rise of aristocratic patronage through delicate craftsmanship and ornate motifs. Both traditions showcase porcelain as a medium of artistic expression and social identity, highlighting distinct cultural narratives in material culture.

Technological Innovations in Porcelain Production

Chinese porcelain pioneered innovations such as kaolin clay use and high-temperature firing techniques, producing thin, translucent, and durable ceramics unmatched for centuries. European porcelain breakthroughs involved the development of hard-paste porcelain in Meissen during the early 18th century, replicating Chinese methods through scientific experimentation with local materials. Advances in glaze formulation, kiln technologies, and decorative techniques differentiated European porcelain while building upon Chinese technological foundations.

Global Trade Influence on Porcelain Development

Chinese porcelain, renowned for its high quality and intricate designs, dominated global trade routes from the Tang Dynasty through the Qing Dynasty, significantly influencing European porcelain production. European artisans, particularly in Meissen and Sevres, replicated Chinese techniques after discovering kaolin deposits essential for true porcelain, driving local industry growth and innovation. The global trade of Chinese porcelain not only shaped artistic styles but also propelled economic competition and technological advancements in European ceramic manufacturing.

Durability and Functional Properties Comparison

Chinese porcelain is renowned for its high durability due to the use of kaolin clay and high firing temperatures, resulting in a dense, vitrified material resistant to chipping and thermal shock. European porcelain, particularly hard-paste varieties developed in Meissen, also exhibits strong durability but often incorporates additional materials such as bone ash, enhancing mechanical strength and translucency. Both types demonstrate excellent functional properties for tableware, yet Chinese porcelain typically outperforms in longevity and resistance to wear under daily use.

Collectibility and Market Value Analysis

Chinese porcelain, renowned for its millennia-old craftsmanship, commands higher collectibility and market value due to its historical significance and rarity, especially pieces from the Ming and Qing dynasties. European porcelain, particularly Meissen and Sevres, holds substantial value for collectors interested in intricate designs and innovation since the 18th century, but generally ranks lower in global auction prices compared to premium Chinese artifacts. Market analysis reveals that provenance, condition, and authenticity significantly influence pricing, with Chinese porcelain often achieving record-breaking sales in prestigious international auctions.

Chinese Porcelain vs European Porcelain Infographic

materialdif.com

materialdif.com