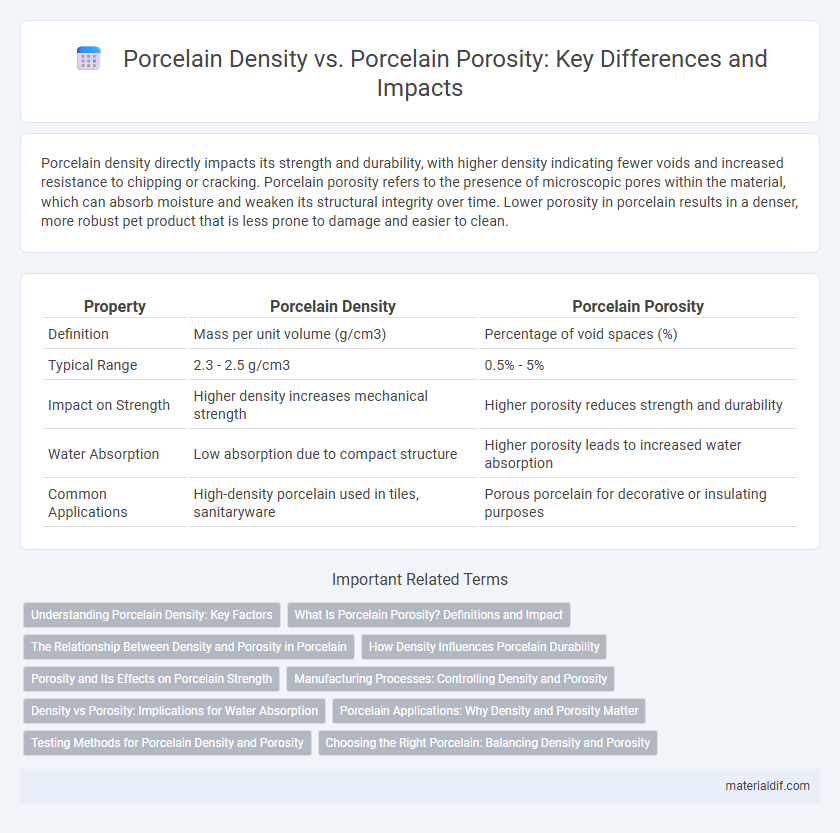

Porcelain density directly impacts its strength and durability, with higher density indicating fewer voids and increased resistance to chipping or cracking. Porcelain porosity refers to the presence of microscopic pores within the material, which can absorb moisture and weaken its structural integrity over time. Lower porosity in porcelain results in a denser, more robust pet product that is less prone to damage and easier to clean.

Table of Comparison

| Property | Porcelain Density | Porcelain Porosity |

|---|---|---|

| Definition | Mass per unit volume (g/cm3) | Percentage of void spaces (%) |

| Typical Range | 2.3 - 2.5 g/cm3 | 0.5% - 5% |

| Impact on Strength | Higher density increases mechanical strength | Higher porosity reduces strength and durability |

| Water Absorption | Low absorption due to compact structure | Higher porosity leads to increased water absorption |

| Common Applications | High-density porcelain used in tiles, sanitaryware | Porous porcelain for decorative or insulating purposes |

Understanding Porcelain Density: Key Factors

Porcelain density directly influences its mechanical strength and durability, with typical values ranging from 2.3 to 2.5 g/cm3, reflecting a tightly packed microstructure. Porosity, usually under 1%, inversely affects density by introducing voids that reduce mass per unit volume and increase permeability. Understanding porcelain density involves analyzing raw material composition, firing temperature, and vitrification level, as these factors determine the extent of densification and the final porosity percentage.

What Is Porcelain Porosity? Definitions and Impact

Porcelain porosity refers to the measure of void spaces or pores within the porcelain material, directly influencing its density and mechanical properties. Higher porcelain porosity reduces density, leading to increased water absorption, decreased strength, and lower durability, while lower porosity results in denser, more compact porcelain that is resistant to moisture and wear. Understanding porcelain porosity is essential for optimizing manufacturing processes and improving the performance of porcelain products in applications such as tiles, sanitaryware, and technical ceramics.

The Relationship Between Density and Porosity in Porcelain

Porcelain density and porosity are inversely related, where higher density typically indicates lower porosity due to reduced void spaces within the ceramic matrix. As porcelain's density increases, its microstructure becomes more compact, enhancing mechanical strength and decreasing water absorption. Optimizing firing temperature and raw material composition directly influences this balance, producing porcelain with desirable low porosity and high durability.

How Density Influences Porcelain Durability

Porcelain density directly impacts its durability by reducing porosity, which minimizes water absorption and enhances resistance to cracking and chipping. Higher density indicates a tightly packed molecular structure, leading to increased strength and longevity under mechanical stress. Consequently, porcelain with greater density exhibits superior durability, making it ideal for both functional and decorative applications.

Porosity and Its Effects on Porcelain Strength

Porosity significantly impacts porcelain strength by introducing microscopic voids that reduce material density and structural integrity. Higher porosity increases the likelihood of crack initiation and propagation, weakening porcelain and diminishing its load-bearing capacity. Controlling porosity through advanced manufacturing techniques enhances porcelain density, resulting in superior mechanical strength and durability.

Manufacturing Processes: Controlling Density and Porosity

Porcelain manufacturing processes meticulously control density and porosity to enhance material strength and durability. Techniques such as precise firing temperatures and sintering durations optimize particle bonding, resulting in higher density and reduced porosity. Managing these parameters ensures the production of porcelain with minimal water absorption and superior mechanical properties.

Density vs Porosity: Implications for Water Absorption

Porcelain density directly influences its porosity, where higher density typically results in lower porosity and reduced water absorption rates. Porcelain with low porosity exhibits minimal water absorption, enhancing durability and resistance to moisture-related damage. Understanding the balance between density and porosity is crucial for optimizing porcelain's performance in wet environments and ensuring long-term structural integrity.

Porcelain Applications: Why Density and Porosity Matter

Porcelain density directly impacts its strength and durability, making it ideal for applications requiring high mechanical stability such as tiles, sanitary ware, and electrical insulators. Porosity influences the material's absorbency and resistance to moisture, which is critical in applications like cookware and artistic ceramics where low water absorption enhances longevity and performance. Understanding the balance between density and porosity allows manufacturers to tailor porcelain products for specific uses, ensuring optimal functionality and reliability.

Testing Methods for Porcelain Density and Porosity

Porcelain density is typically measured using the Archimedes method, which involves weighing a porcelain sample in air and submerged in water to calculate its bulk density. Porosity testing for porcelain often employs mercury intrusion porosimetry or water absorption tests to determine the volume of pores within the ceramic structure. Both density and porosity testing are critical for assessing porcelain's mechanical strength, durability, and suitability for various applications.

Choosing the Right Porcelain: Balancing Density and Porosity

Porcelain density typically ranges from 2.3 to 2.5 g/cm3, indicating a compact, strong material ideal for durable applications. Porosity in porcelain, often below 0.5%, affects water absorption and impacts resistance to staining and frost damage. Choosing the right porcelain requires balancing higher density for strength and lower porosity for durability based on the intended use, such as tiles, tableware, or sanitary ware.

Porcelain density vs Porcelain porosity Infographic

materialdif.com

materialdif.com