High-fire porcelain is fired at temperatures between 2300degF and 2500degF, resulting in a denser, more durable, and less porous material ideal for fine art pieces and functional ware requiring strength. Low-fire porcelain, fired between 1828degF and 2167degF, offers a wider range of vibrant glaze effects but tends to be more fragile and porous, suitable for decorative items. Choosing between high-fire and low-fire porcelain depends on the desired balance of durability and aesthetic qualities.

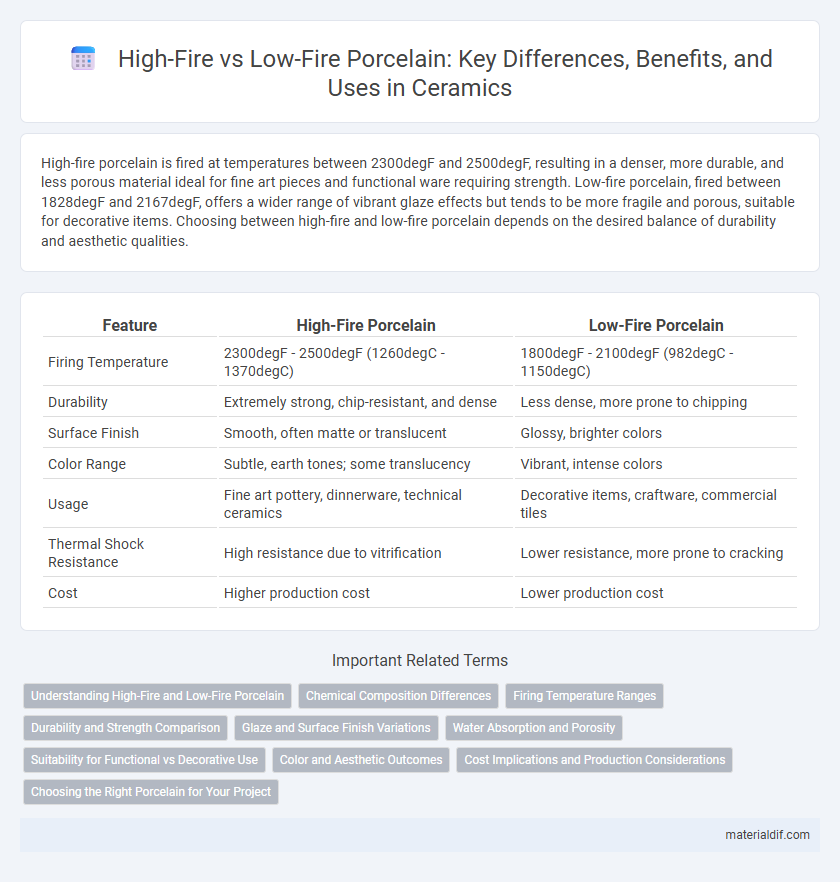

Table of Comparison

| Feature | High-Fire Porcelain | Low-Fire Porcelain |

|---|---|---|

| Firing Temperature | 2300degF - 2500degF (1260degC - 1370degC) | 1800degF - 2100degF (982degC - 1150degC) |

| Durability | Extremely strong, chip-resistant, and dense | Less dense, more prone to chipping |

| Surface Finish | Smooth, often matte or translucent | Glossy, brighter colors |

| Color Range | Subtle, earth tones; some translucency | Vibrant, intense colors |

| Usage | Fine art pottery, dinnerware, technical ceramics | Decorative items, craftware, commercial tiles |

| Thermal Shock Resistance | High resistance due to vitrification | Lower resistance, more prone to cracking |

| Cost | Higher production cost | Lower production cost |

Understanding High-Fire and Low-Fire Porcelain

High-fire porcelain is fired at temperatures above 2300degF (1260degC), resulting in a dense, vitrified, and durable ceramic body with a glassy surface and enhanced resistance to chipping and thermal shock. Low-fire porcelain, fired between 1800degF and 2100degF (982degC to 1149degC), maintains a more porous structure with brighter glaze colors but less strength and durability compared to high-fire porcelain. Understanding the firing temperature differences helps in selecting the appropriate porcelain type for applications requiring specific strength, translucency, or aesthetic qualities.

Chemical Composition Differences

High-fire porcelain typically contains higher amounts of kaolin, feldspar, and quartz, resulting in a vitrified, dense body fired at temperatures above 1,200degC. Low-fire porcelain includes increased fluxes and lower silica content, allowing it to mature at temperatures between 1,000degC and 1,100degC but producing a more porous and less vitrified ceramic. The chemical composition directly influences durability, translucency, and strength variations between high-fire and low-fire porcelain.

Firing Temperature Ranges

High-fire porcelain is typically fired at temperatures between 2300degF and 2500degF (1260degC to 1370degC), resulting in a dense, vitrified body with enhanced durability and translucency. Low-fire porcelain is fired at lower temperatures, around 1800degF to 2100degF (980degC to 1150degC), which produces a more porous and less durable ceramic but allows for brighter glaze colors. The firing temperature impacts the porcelain's final strength, porosity, and aesthetic qualities crucial for different artistic and functional applications.

Durability and Strength Comparison

High-fire porcelain, fired at temperatures above 2300degF (1260degC), exhibits superior durability and strength due to its vitrified, dense structure that resists chipping and cracking under stress. Low-fire porcelain, fired below 2200degF (1200degC), tends to be softer and more porous, making it less resistant to impacts and wear over time. The increased hardness and reduced porosity of high-fire porcelain make it ideal for heavy-use applications, while low-fire porcelain is better suited for decorative or low-stress environments.

Glaze and Surface Finish Variations

High-fire porcelain, fired at temperatures above 2300degF (1260degC), develops a vitrified, durable surface with subtle glaze variations that often result in a smooth, glass-like finish. Low-fire porcelain, typically fired between 1800degF and 2100degF (982degC-1149degC), allows for a broader range of glaze colors and textures, achieving more vibrant and matte or satin surface finishes. The glaze formulation and firing temperature directly influence the porcelain's final appearance, durability, and tactile qualities.

Water Absorption and Porosity

High-fire porcelain vitrifies at temperatures above 2300degF, resulting in low porosity and minimal water absorption below 0.5%, which enhances durability and resistance to stains. Low-fire porcelain, fired at temperatures around 1800degF, exhibits higher porosity and water absorption rates typically above 3%, making it more susceptible to moisture damage. The lower vitrification in low-fire porcelain impacts its strength, whereas high-fire porcelain's dense structure provides superior impermeability and longevity.

Suitability for Functional vs Decorative Use

High-fire porcelain, fired at temperatures above 2300degF (1260degC), offers superior strength and durability, making it ideal for functional items such as dinnerware and cookware that require resistance to chipping and thermal shock. Low-fire porcelain, fired between 1800degF and 2100degF (980degC to 1150degC), often achieves more vibrant and varied glazes, making it better suited for decorative pieces like art sculptures and ornamental tiles. The choice between high-fire and low-fire porcelain depends on whether the primary use demands mechanical resilience or aesthetic enhancement.

Color and Aesthetic Outcomes

High-fire porcelain, fired at temperatures above 2300degF (1260degC), results in a dense, vitrified body with subtle, often muted colors and a smooth matte or satin finish, enhancing durability and classic aesthetics. Low-fire porcelain, fired between 1828degF to 2167degF (998degC to 1186degC), allows for a wider and more vibrant color palette, including bright glazes and detailed surface designs, but tends to be more porous and less dense. Choosing between high-fire and low-fire porcelain impacts the final color intensity, texture, and overall visual appeal, with high-fire porcelain favoring understated elegance and low-fire porcelain emphasizing vivid, decorative effects.

Cost Implications and Production Considerations

High-fire porcelain requires kilns reaching temperatures above 2300degF, resulting in higher energy costs but producing denser, more durable ware with reduced porosity. Low-fire porcelain, fired at approximately 1828degF to 2012degF, lowers energy consumption and allows faster production cycles, though it may yield slightly less robust products. Manufacturers must weigh initial kiln investment and operational expenses against desired product quality and production speed when choosing between high-fire and low-fire porcelain techniques.

Choosing the Right Porcelain for Your Project

High-fire porcelain, fired at temperatures above 2300degF (1260degC), offers superior strength, durability, and a vitreous, non-porous surface ideal for functional ware and fine art pieces requiring resilience. Low-fire porcelain, fired between 1828degF to 2100degF (998degC to 1150degC), provides brighter, more vivid colors and a broader palette for decorative work but is slightly more porous and less durable than high-fire. Selecting the right porcelain depends on the project's functional demands and aesthetic goals, balancing factors like durability, color intensity, and firing constraints.

High-Fire Porcelain vs Low-Fire Porcelain Infographic

materialdif.com

materialdif.com