Porcelain slipcasting offers precise, consistent shapes by pouring liquid clay into plaster molds, ideal for complex or repetitive designs, while porcelain hand-thrown pottery relies on the artisan's skill on the wheel, allowing for unique, organic forms with subtle variations. Slipcasting enables mass production with fine detail and uniformity, whereas hand-throwing emphasizes craftsmanship and individual expression. Both techniques highlight the delicate nature and translucency of porcelain, but achieve differing aesthetics and production efficiencies.

Table of Comparison

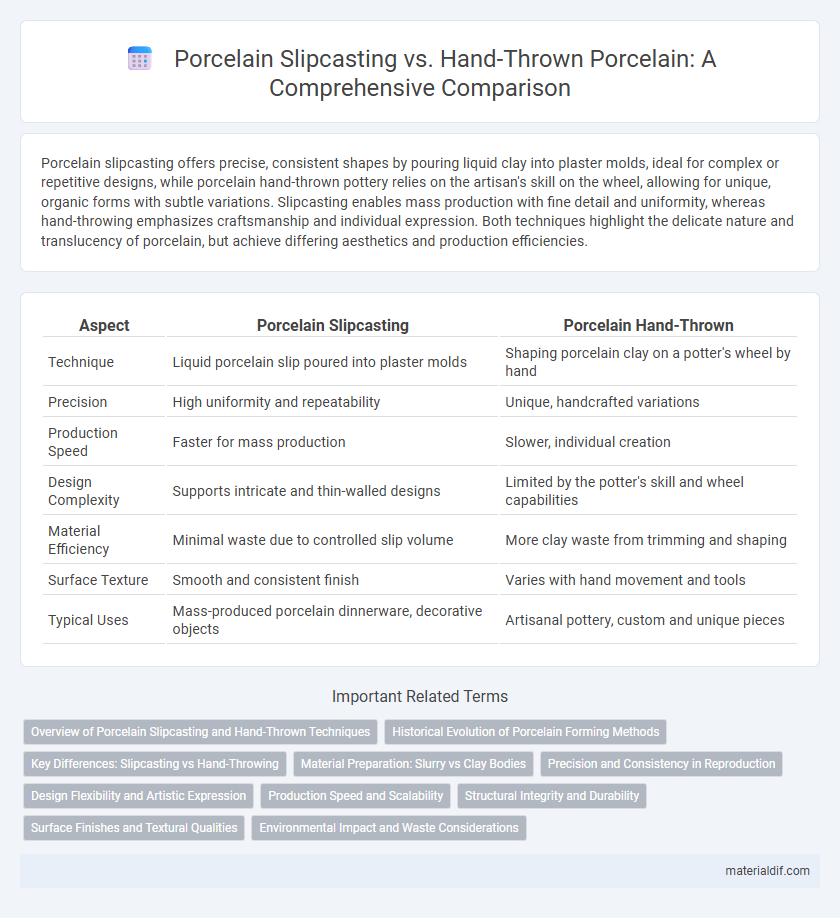

| Aspect | Porcelain Slipcasting | Porcelain Hand-Thrown |

|---|---|---|

| Technique | Liquid porcelain slip poured into plaster molds | Shaping porcelain clay on a potter's wheel by hand |

| Precision | High uniformity and repeatability | Unique, handcrafted variations |

| Production Speed | Faster for mass production | Slower, individual creation |

| Design Complexity | Supports intricate and thin-walled designs | Limited by the potter's skill and wheel capabilities |

| Material Efficiency | Minimal waste due to controlled slip volume | More clay waste from trimming and shaping |

| Surface Texture | Smooth and consistent finish | Varies with hand movement and tools |

| Typical Uses | Mass-produced porcelain dinnerware, decorative objects | Artisanal pottery, custom and unique pieces |

Overview of Porcelain Slipcasting and Hand-Thrown Techniques

Porcelain slipcasting involves pouring liquid porcelain slip into plaster molds, allowing for precise replication of intricate shapes and consistent thickness, making it ideal for mass production. In contrast, porcelain hand-thrown techniques require skilled artisans to shape clay on a potter's wheel, resulting in unique, handcrafted pieces with subtle variations and a more tactile aesthetic. Both methods demand high-temperature firing to attain porcelain's characteristic strength and translucency, but slipcasting emphasizes accuracy and repeatability, while hand-throwing highlights individual craftsmanship.

Historical Evolution of Porcelain Forming Methods

Porcelain slipcasting emerged in the late 18th century as a revolutionary technique allowing precise and consistent reproduction of intricate shapes by pouring liquid porcelain slip into plaster molds, contrasting with the centuries-old hand-thrown method that relied on skilled artisans shaping clay on a potter's wheel. The hand-thrown porcelain tradition dates back to the Tang Dynasty in China, representing a highly tactile and artistic approach to creating unique pieces with subtle variations in form and thickness. Technological advancements in slip formulation and mold-making during the Industrial Revolution accelerated the widespread adoption of slipcasting, enabling mass production while hand-throwing remained synonymous with craftsmanship and individual expression.

Key Differences: Slipcasting vs Hand-Throwing

Porcelain slipcasting involves pouring liquid clay slip into plaster molds, allowing precise replication of intricate shapes with minimal manual skill. In contrast, porcelain hand-throwing requires skilled artisans to shape the clay on a potter's wheel, offering unique, individualized forms and surface textures. Slipcasting excels in mass production and consistency, while hand-throwing prioritizes artistic expression and tactile variation.

Material Preparation: Slurry vs Clay Bodies

Porcelain slipcasting utilizes a liquid slurry made from refined porcelain powder suspended in water, ensuring uniform consistency and enabling precise, thin-walled shapes through molds. In contrast, porcelain hand-thrown techniques rely on plastic clay bodies composed of porcelain clay mixed with water to achieve pliability, requiring skilled manipulation on the wheel. The slurry in slipcasting allows for mass production with minimal waste, while the clay bodies in hand-throwing provide tactile feedback and variation in texture.

Precision and Consistency in Reproduction

Porcelain slipcasting offers superior precision and consistency in reproduction compared to porcelain hand-thrown methods, as the liquid slip fills detailed molds to replicate exact shapes and intricate designs with minimal variation. Hand-thrown porcelain, while allowing for artistic variation and unique textures, often results in slight inconsistencies due to the manual shaping process. Slipcasting excels in mass production scenarios where uniformity in size, thickness, and detail is essential for high-quality porcelain products.

Design Flexibility and Artistic Expression

Porcelain slipcasting offers superior design flexibility by enabling the creation of intricate shapes and consistent reproductions through liquid clay poured into molds. In contrast, porcelain hand-thrown techniques emphasize artistic expression, allowing potters to impart unique textures and organic forms through tactile manipulation on the wheel. Both methods impact the final aesthetic, with slipcasting favoring precision and repeatability, while hand-throwing highlights individual craftsmanship and spontaneity.

Production Speed and Scalability

Porcelain slipcasting offers significantly faster production speeds and higher scalability compared to hand-thrown porcelain, enabling mass reproduction with consistent quality through mold use. Hand-thrown porcelain requires skilled artisans and is limited by individual craftsmanship, making it less efficient for large-scale production. Slipcasting's mechanized process reduces labor time and allows for uniform replication, making it ideal for commercial-scale porcelain manufacturing.

Structural Integrity and Durability

Porcelain slipcasting ensures consistent wall thickness and reduces air pockets, enhancing structural integrity and durability compared to hand-thrown pieces, which may have variable thickness and potential weak points. The controlled process of slipcasting produces porcelain with uniform density and fewer imperfections, leading to higher resistance against cracking and chipping. Hand-thrown porcelain, while unique in texture and form, often requires greater skill to achieve comparable strength and longevity.

Surface Finishes and Textural Qualities

Porcelain slipcasting produces smooth, uniform surface finishes due to the liquid clay mixture perfectly filling the mold, resulting in fine details and consistent texture. Hand-thrown porcelain, by contrast, showcases subtle variations and organic textures from the potter's touch, offering tactile depth and unique character. These textural qualities make slipcasting ideal for precision and replication, while hand-throwing emphasizes artistry and individual expression in porcelain ware.

Environmental Impact and Waste Considerations

Porcelain slipcasting minimizes raw material waste by using liquid clay poured into reusable molds, enabling precise control over thickness and reducing excess scrap compared to hand-thrown methods. Hand-thrown porcelain often generates more waste through trimming and uneven shaping, resulting in discarded clay and higher water usage during the throwing and cleaning processes. Slipcasting supports sustainable production with lower energy consumption and cleaner runoff, while hand-thrown techniques require more intensive shaping and drying, increasing environmental impact.

Porcelain slipcasting vs Porcelain hand-thrown Infographic

materialdif.com

materialdif.com