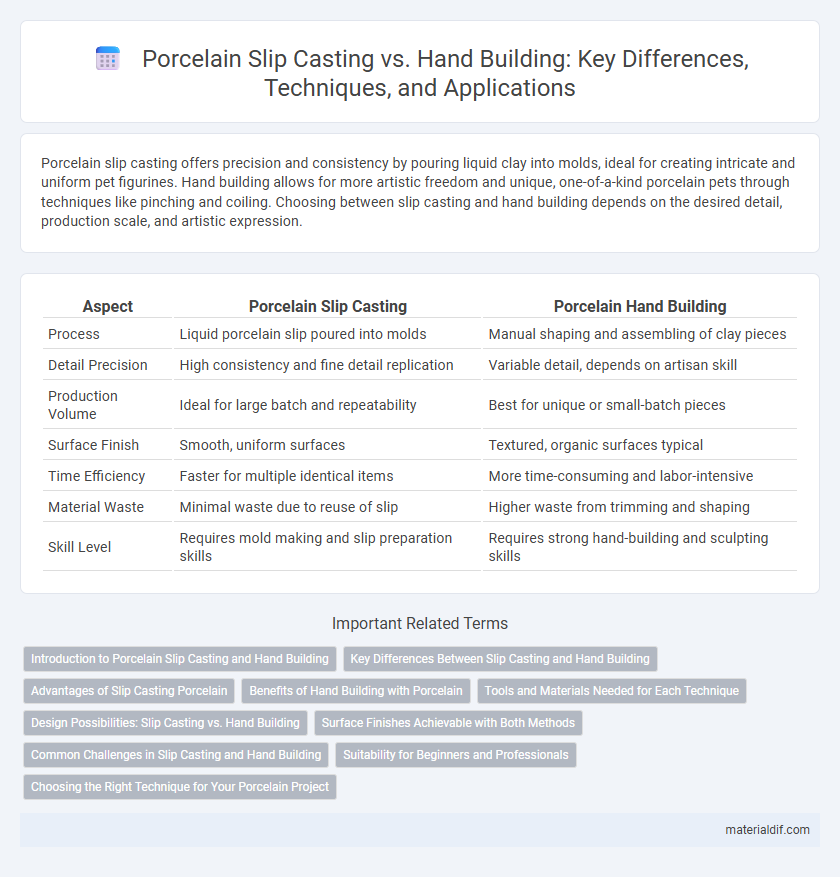

Porcelain slip casting offers precision and consistency by pouring liquid clay into molds, ideal for creating intricate and uniform pet figurines. Hand building allows for more artistic freedom and unique, one-of-a-kind porcelain pets through techniques like pinching and coiling. Choosing between slip casting and hand building depends on the desired detail, production scale, and artistic expression.

Table of Comparison

| Aspect | Porcelain Slip Casting | Porcelain Hand Building |

|---|---|---|

| Process | Liquid porcelain slip poured into molds | Manual shaping and assembling of clay pieces |

| Detail Precision | High consistency and fine detail replication | Variable detail, depends on artisan skill |

| Production Volume | Ideal for large batch and repeatability | Best for unique or small-batch pieces |

| Surface Finish | Smooth, uniform surfaces | Textured, organic surfaces typical |

| Time Efficiency | Faster for multiple identical items | More time-consuming and labor-intensive |

| Material Waste | Minimal waste due to reuse of slip | Higher waste from trimming and shaping |

| Skill Level | Requires mold making and slip preparation skills | Requires strong hand-building and sculpting skills |

Introduction to Porcelain Slip Casting and Hand Building

Porcelain slip casting involves pouring liquid porcelain slip into plaster molds to create precise, detailed shapes with consistent thickness and smooth surfaces. Hand building with porcelain uses techniques like pinching, coiling, and slab construction to shape the clay manually, allowing for more organic and unique forms but requiring careful control to avoid warping and cracking during drying. Both methods demand expertise in managing porcelain's delicate properties, including its high firing temperature of around 1300degC and its tendency to shrink significantly during firing.

Key Differences Between Slip Casting and Hand Building

Slip casting uses liquid porcelain slip poured into molds to create precise, uniform shapes ideal for mass production, while hand building involves manually shaping clay with tools and hands, allowing for more organic, unique forms. Slip casting offers high consistency and fine detail replication, whereas hand building provides artistic flexibility and expressive textures. Differences center on production speed, repeatability, and the degree of creative control artisans have over the final porcelain piece.

Advantages of Slip Casting Porcelain

Slip casting porcelain offers superior precision and uniformity compared to hand building, enabling the reproduction of complex shapes with consistent wall thickness. This method reduces material waste and enhances production efficiency, making it ideal for mass production of intricate porcelain items. The use of porous plaster molds in slip casting ensures rapid moisture absorption, resulting in faster drying times and improved surface finish quality.

Benefits of Hand Building with Porcelain

Hand building with porcelain offers greater artistic control and allows for intricate, unique shapes that slip casting cannot easily achieve. This method enhances tactile engagement with the material, promoting a deeper connection between the artist and the porcelain. Hand-built porcelain pieces often exhibit distinctive textures and organic forms, increasing their aesthetic and collectible value.

Tools and Materials Needed for Each Technique

Porcelain slip casting requires a plaster mold, fluid porcelain slip, and precise pouring tools to achieve smooth, uniform shapes ideal for mass production. Hand building porcelain demands basic tools such as wire cutters, wooden modeling tools, sponges, and a work surface, allowing artists more tactile control for unique, textured pieces. Both techniques need porcelain clay, but slip casting emphasizes mold-making materials while hand building focuses on manual shaping instruments.

Design Possibilities: Slip Casting vs. Hand Building

Porcelain slip casting enables the creation of highly detailed and reproducible shapes, allowing for intricate designs and complex geometries that are difficult to achieve by hand. Hand building provides greater flexibility for unique, sculptural forms and organic textures, offering artists the freedom to experiment with asymmetry and personal expression. The choice between slip casting and hand building depends on whether precision and uniformity or individuality and creative spontaneity are the primary design goals.

Surface Finishes Achievable with Both Methods

Porcelain slip casting produces highly smooth and uniform surface finishes due to the liquid clay forming thin, consistent walls within the mold, ideal for intricate shapes and detailed textures. Hand building allows for varied surface textures, ranging from rough and organic to finely detailed patterns, giving artists greater tactile control but with less uniformity compared to slip casting. Both methods can achieve glossy or matte finishes through firing and glazing, but slip casting often yields more precise and polished results.

Common Challenges in Slip Casting and Hand Building

Porcelain slip casting often faces challenges such as controlling slip viscosity and preventing air bubbles, which can cause weak spots or surface imperfections. Hand building porcelain requires skillful manipulation to avoid cracking and warping during drying due to porcelain's low plasticity. Both methods demand precise moisture management to ensure structural integrity and a smooth finish in the final product.

Suitability for Beginners and Professionals

Porcelain slip casting offers precision and repeatability, making it ideal for beginners seeking consistent forms and professionals aiming for detailed, complex shapes. Hand building with porcelain allows greater creative freedom and tactile control, appealing to experienced ceramicists who prioritize artistic expression over uniformity. Beginners may find slip casting more accessible due to its streamlined process, while professionals benefit from hand building's versatility in custom, unique designs.

Choosing the Right Technique for Your Porcelain Project

Porcelain slip casting offers precision and uniformity, ideal for producing intricate, repeatable shapes with smooth surfaces. Hand building allows for greater artistic expression and uniqueness, perfect for custom forms and organic textures. Selecting the right technique depends on your project's complexity, desired finish, and production scale.

Porcelain Slip Casting vs Hand Building Infographic

materialdif.com

materialdif.com