Dense porcelain offers superior durability and resistance to wear, making it ideal for heavy-use applications such as flooring and countertops. Lightweight porcelain provides easier handling and installation without compromising aesthetic appeal, suited for wall cladding and decorative elements. Both types maintain the inherent strength and water resistance characteristic of high-quality porcelain.

Table of Comparison

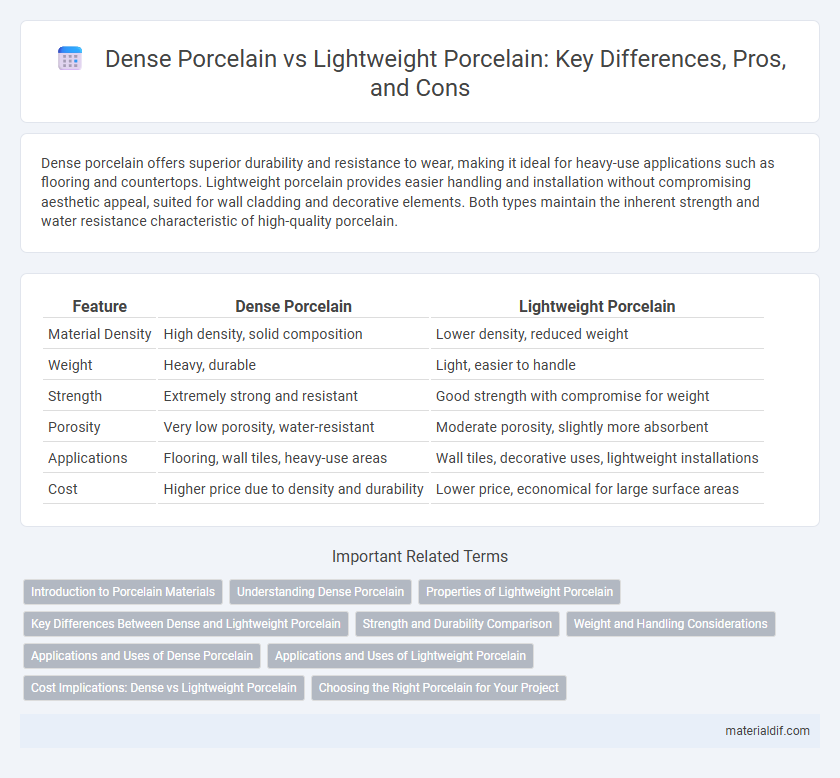

| Feature | Dense Porcelain | Lightweight Porcelain |

|---|---|---|

| Material Density | High density, solid composition | Lower density, reduced weight |

| Weight | Heavy, durable | Light, easier to handle |

| Strength | Extremely strong and resistant | Good strength with compromise for weight |

| Porosity | Very low porosity, water-resistant | Moderate porosity, slightly more absorbent |

| Applications | Flooring, wall tiles, heavy-use areas | Wall tiles, decorative uses, lightweight installations |

| Cost | Higher price due to density and durability | Lower price, economical for large surface areas |

Introduction to Porcelain Materials

Dense porcelain features a compact microstructure with minimal porosity, providing superior strength, durability, and resistance to moisture and staining. Lightweight porcelain incorporates advanced formulations and manufacturing techniques to reduce density without compromising performance, making it ideal for applications requiring easier handling and installation. Both types offer distinct benefits tailored to specific architectural and design needs, balancing robustness with versatility.

Understanding Dense Porcelain

Dense porcelain exhibits a high degree of vitrification, resulting in a compact, non-porous structure with superior strength and durability compared to lightweight porcelain. Its dense composition enhances resistance to moisture absorption, thermal shock, and mechanical wear, making it ideal for applications requiring long-lasting performance such as tile flooring and high-end dinnerware. Manufacturers achieve this density through a refined firing process and precise clay body formulation, which contributes to the material's characteristic smooth finish and robustness.

Properties of Lightweight Porcelain

Lightweight porcelain is characterized by its reduced density, making it significantly lighter than dense porcelain while maintaining durability and strength. It offers enhanced thermal insulation and improved handling ease, ideal for modern applications requiring both aesthetic appeal and functional performance. The porous microstructure of lightweight porcelain contributes to its lower weight without compromising resistance to heat, moisture, and wear.

Key Differences Between Dense and Lightweight Porcelain

Dense porcelain features a higher clay and mineral composition resulting in greater durability, water resistance, and density typically exceeding 2.3 g/cm3, making it ideal for heavy-traffic areas and outdoor use. Lightweight porcelain contains more air pockets and lower density, usually below 2.1 g/cm3, offering easier handling and installation while still maintaining reasonable strength and aesthetic appeal. The key differences lie in their density, weight, durability, and suitability for specific applications such as structural support versus decorative tiling.

Strength and Durability Comparison

Dense porcelain exhibits superior strength and durability due to its low porosity and tightly packed molecular structure, making it highly resistant to chipping and cracking. Lightweight porcelain, while easier to handle and install, compromises some structural integrity and is more prone to damage under heavy impact or prolonged stress. Choosing dense porcelain ensures longer-lasting performance in high-traffic areas requiring robust, wear-resistant surfaces.

Weight and Handling Considerations

Dense porcelain offers greater durability and a heavier weight, providing a solid, sturdy feel ideal for applications requiring strength and longevity. Lightweight porcelain reduces overall mass, making it easier to handle and install, which benefits projects with weight restrictions or frequent movement needs. Choosing between dense and lightweight porcelain depends on balancing weight requirements with handling simplicity and installation demands.

Applications and Uses of Dense Porcelain

Dense porcelain features a high concentration of fine clays and minerals, resulting in superior strength and durability ideal for heavy-use applications such as industrial insulators, high-traffic flooring, and advanced sanitary wares. Its low porosity enhances resistance to moisture, chemicals, and thermal shock, making it suitable for laboratory equipment and high-performance tiles in commercial buildings. The material's robustness and density also support its use in precision electrical components and durable architectural facades where longevity is critical.

Applications and Uses of Lightweight Porcelain

Lightweight porcelain is ideal for applications requiring ease of installation and reduced structural load, such as large-format wall cladding and expansive flooring projects in commercial and residential spaces. Its reduced density enhances handling and transport efficiency while maintaining durability, making it popular for facades, countertops, and decorative elements. Lightweight porcelain is especially beneficial in renovation projects where weight constraints are critical without compromising aesthetic appeal and resistance to wear.

Cost Implications: Dense vs Lightweight Porcelain

Dense porcelain typically incurs higher manufacturing and material costs due to its compact composition and durability, resulting in a steeper purchase price and installation expense compared to lightweight porcelain. Lightweight porcelain offers cost advantages by reducing transportation and labor fees owing to its easier handling and lower weight, making it a budget-friendly option for large-scale projects. Choosing between dense and lightweight porcelain depends on balancing upfront investment against long-term performance and maintenance costs.

Choosing the Right Porcelain for Your Project

Dense porcelain offers superior durability and water resistance, making it ideal for high-traffic commercial spaces or outdoor installations exposed to harsh weather. Lightweight porcelain provides easier handling and installation, suitable for residential projects or areas requiring reduced structural load. Selecting the right porcelain depends on balancing factors like strength requirements, installation complexity, and environmental exposure to ensure optimal performance and longevity.

Dense Porcelain vs Lightweight Porcelain Infographic

materialdif.com

materialdif.com