Porcelain slip casting offers precise and consistent shapes by pouring liquid clay into molds, ideal for complex designs and mass production. Hand throwing on the wheel allows for more artistic expression and subtle variations, making each piece unique with organic imperfections. Both techniques require skill but differ in production scale, texture, and design flexibility.

Table of Comparison

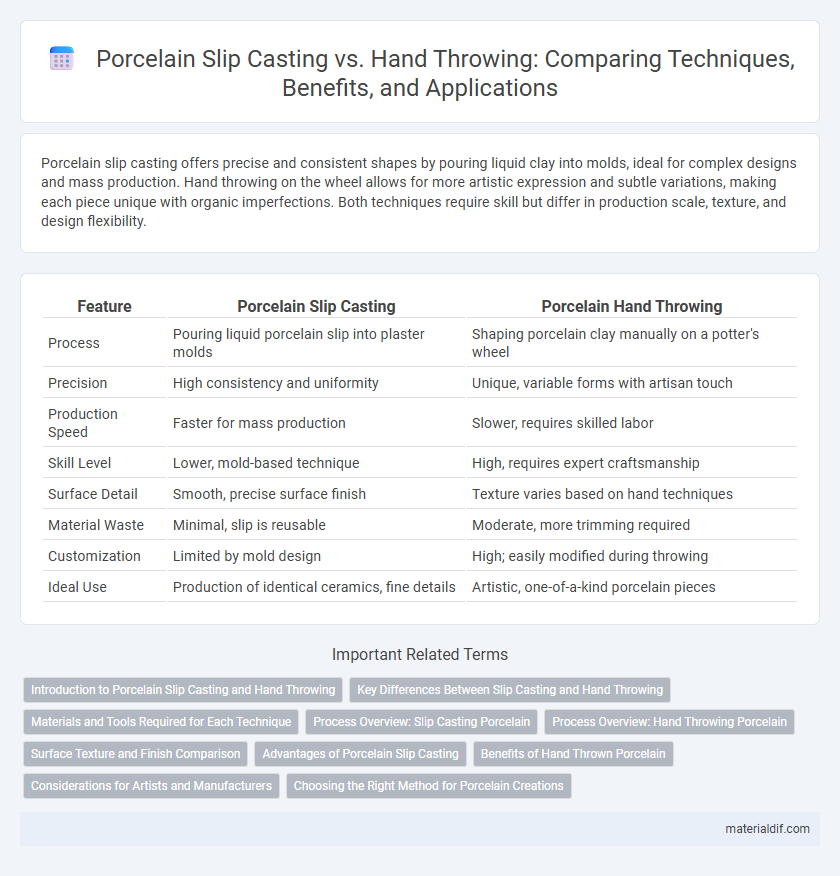

| Feature | Porcelain Slip Casting | Porcelain Hand Throwing |

|---|---|---|

| Process | Pouring liquid porcelain slip into plaster molds | Shaping porcelain clay manually on a potter's wheel |

| Precision | High consistency and uniformity | Unique, variable forms with artisan touch |

| Production Speed | Faster for mass production | Slower, requires skilled labor |

| Skill Level | Lower, mold-based technique | High, requires expert craftsmanship |

| Surface Detail | Smooth, precise surface finish | Texture varies based on hand techniques |

| Material Waste | Minimal, slip is reusable | Moderate, more trimming required |

| Customization | Limited by mold design | High; easily modified during throwing |

| Ideal Use | Production of identical ceramics, fine details | Artistic, one-of-a-kind porcelain pieces |

Introduction to Porcelain Slip Casting and Hand Throwing

Porcelain slip casting involves pouring liquid clay into plaster molds, allowing for precise replication of intricate shapes and fine details, making it ideal for mass production. Hand throwing, on the other hand, uses a potter's wheel to shape porcelain clay manually, emphasizing skilled craftsmanship and unique, organic forms. Both techniques highlight the versatility of porcelain but differ significantly in terms of process control, texture, and artistic expression.

Key Differences Between Slip Casting and Hand Throwing

Porcelain slip casting involves pouring liquid clay slip into molds, enabling precise replication of intricate shapes with consistent thickness and smooth surfaces, ideal for mass production. Hand throwing porcelain requires skillful manipulation on a potter's wheel, allowing for unique organic forms but often exhibiting slight variations in symmetry and wall thickness. The key differences lie in the consistency and scale of production, with slip casting favoring uniformity and efficiency while hand throwing emphasizes artisanal value and individual craftsmanship.

Materials and Tools Required for Each Technique

Porcelain slip casting requires fine porcelain clay mixed with water to create a liquid slip, which is poured into plaster molds to form precise shapes; essential tools include mixing containers, plaster molds, and trimming tools for detailing. Hand throwing porcelain involves using a high-quality porcelain clay body with a smooth, plastic consistency, and tools such as a potter's wheel, ribs, sponges, and wire cutters to shape and finish the piece. Both techniques demand careful control of moisture and temperature to maintain porcelain's characteristic translucency and strength.

Process Overview: Slip Casting Porcelain

Slip casting porcelain involves pouring liquid clay slip into a plaster mold, allowing the moisture to be absorbed and forming a consistent, thin clay shell inside the mold. The process ensures precise replication of intricate designs and smooth surfaces, ideal for mass production of delicate porcelain items. After the desired thickness is achieved, excess slip is poured out, and the cast piece is left to dry before further refinement and firing.

Process Overview: Hand Throwing Porcelain

Hand throwing porcelain involves shaping the clay on a rotating potter's wheel, requiring skilled manual control to create symmetrical forms. This traditional technique allows for unique, individual pieces with varied textures and thicknesses, reflecting the potter's artistry. The process demands precise timing and moisture management to maintain porcelain's delicate consistency during shaping.

Surface Texture and Finish Comparison

Porcelain slip casting produces smooth, uniform surface textures due to liquid clay filling molds, resulting in consistent finishes ideal for intricate designs and mass production. Hand throwing on a potter's wheel creates more varied surface textures with subtle ridges and organic imperfections, giving each piece a unique tactile quality and aesthetic depth. The slip cast porcelain often exhibits a flawless, polished finish, while hand-thrown porcelain offers a more tactile and personalized glaze interaction.

Advantages of Porcelain Slip Casting

Porcelain slip casting offers precise replication of intricate designs, enabling consistent production of fine details that hand throwing often cannot achieve. This method allows for faster and more efficient mass production of complex porcelain pieces, reducing labor costs and material waste. The use of molds in slip casting ensures uniform thickness and smooth surfaces, enhancing the overall quality and durability of porcelain products.

Benefits of Hand Thrown Porcelain

Hand thrown porcelain offers superior control over thickness and shape, resulting in unique, one-of-a-kind pieces with intricate details and subtle variations. This method allows for greater artistic expression and tactile connection with the material, enhancing the finesse and texture of the final ceramic product. Unlike slip casting, hand throwing also reduces mold dependency, enabling more sustainable and flexible craftsmanship.

Considerations for Artists and Manufacturers

Porcelain slip casting offers artists and manufacturers precise replication and complex shape production, ideal for large-scale or intricate designs, whereas hand throwing provides greater tactile control and unique, one-of-a-kind pieces with subtle variations. Considerations include the scale of production, desired texture, and the level of customization, as slip casting requires molds and is more efficient for mass production, while hand throwing demands skilled craftsmanship and allows for artistic expression. Material properties like porcelain's fine particle size and susceptibility to cracking influence the choice, as slip casting handles thin, delicate forms better, whereas hand throwing benefits from dynamic shaping during the throwing process.

Choosing the Right Method for Porcelain Creations

Choosing between porcelain slip casting and hand throwing depends on the desired level of precision and production volume, as slip casting allows for consistent replication of intricate shapes through poured liquid clay into molds. Hand throwing offers unique tactile control and organic variation, ideal for one-of-a-kind pieces emphasizing craftsmanship and artistic expression. Assess factors like design complexity, time constraints, and skill level to select the most suitable method for porcelain creations.

Porcelain Slip Casting vs Hand Throwing Infographic

materialdif.com

materialdif.com