Porcelain is a type of ceramic known for its higher density, durability, and translucency compared to standard ceramics, making it more resistant to chipping and moisture. While both materials are made from clay fired at high temperatures, porcelain undergoes a more refined manufacturing process with kaolin clay and is fired at higher temperatures, resulting in a harder, non-porous surface. These qualities make porcelain ideal for fine dinnerware, tiles, and bathroom fixtures where strength and aesthetic appeal are essential.

Table of Comparison

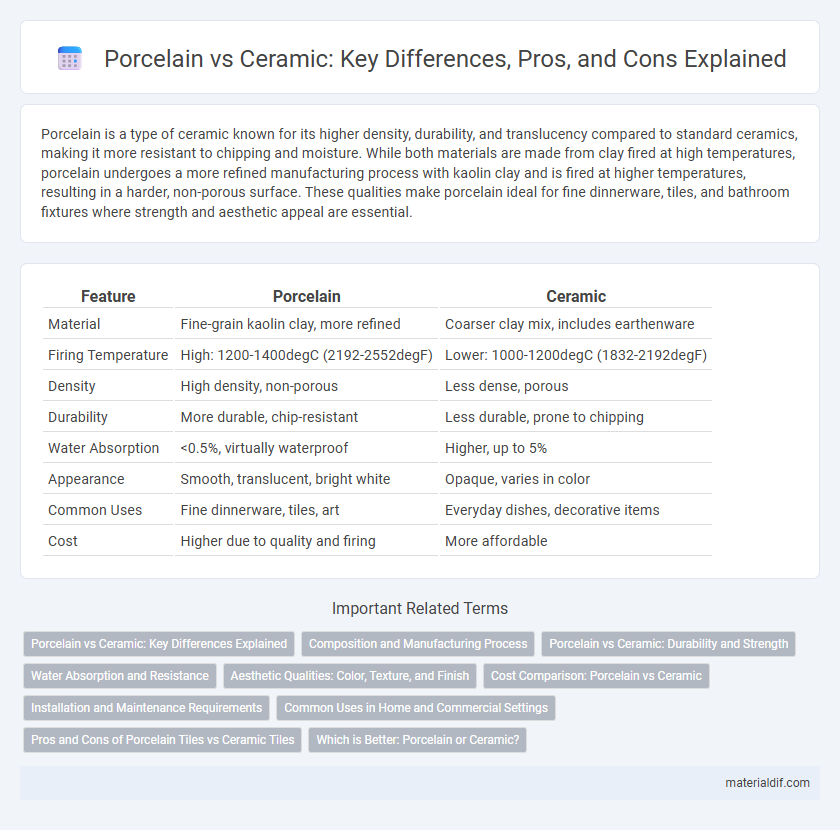

| Feature | Porcelain | Ceramic |

|---|---|---|

| Material | Fine-grain kaolin clay, more refined | Coarser clay mix, includes earthenware |

| Firing Temperature | High: 1200-1400degC (2192-2552degF) | Lower: 1000-1200degC (1832-2192degF) |

| Density | High density, non-porous | Less dense, porous |

| Durability | More durable, chip-resistant | Less durable, prone to chipping |

| Water Absorption | <0.5%, virtually waterproof | Higher, up to 5% |

| Appearance | Smooth, translucent, bright white | Opaque, varies in color |

| Common Uses | Fine dinnerware, tiles, art | Everyday dishes, decorative items |

| Cost | Higher due to quality and firing | More affordable |

Porcelain vs Ceramic: Key Differences Explained

Porcelain and ceramic differ primarily in composition and firing temperature, with porcelain made from finer clay fired at higher temperatures, resulting in a denser, more durable material. Porcelain's non-porous nature makes it highly resistant to moisture, stains, and thermal shock, unlike regular ceramic which is more porous and susceptible to chipping. These characteristics make porcelain ideal for high-traffic applications like tiles and dinnerware, whereas ceramic suits decorative uses and low-impact environments.

Composition and Manufacturing Process

Porcelain is made from a refined clay mixture primarily consisting of kaolin, feldspar, and quartz, fired at temperatures between 1,200 and 1,400 degrees Celsius, resulting in a dense, glass-like, and non-porous material. Ceramic typically uses a broader range of clay with additives and is fired at slightly lower temperatures, making it more porous and less translucent than porcelain. The manufacturing process of porcelain involves precise control of raw material purity and high-temperature vitrification, differentiating it from the more varied and lower-fired ceramic production.

Porcelain vs Ceramic: Durability and Strength

Porcelain, made from refined clay fired at higher temperatures, exhibits greater durability and strength than traditional ceramic, which uses coarser clay and lower firing temperatures. Its dense, non-porous structure enhances resistance to chipping, cracking, and moisture absorption, making it ideal for high-traffic areas and daily use. In contrast, ceramic is more porous and prone to damage under heavy impact, limiting its suitability for environments requiring superior toughness.

Water Absorption and Resistance

Porcelain exhibits significantly lower water absorption rates, typically less than 0.5%, compared to ceramic which can absorb between 3-7%, making porcelain more resistant to moisture and ideal for environments with high humidity. The dense, vitrified structure of porcelain enhances its resistance to water damage, staining, and frost, whereas ceramic's higher porosity makes it more susceptible to water infiltration and potential cracking. This superior water resistance makes porcelain the preferred material for both indoor and outdoor applications where durability and low maintenance are critical.

Aesthetic Qualities: Color, Texture, and Finish

Porcelain exhibits a refined aesthetic characterized by its translucent white color, smooth texture, and glossy finish, distinguishing it from ceramic, which often displays a more varied palette and a coarser surface. The dense composition of porcelain allows for a delicate yet durable appearance, ideal for fine art and upscale tableware. Ceramic's porous nature results in a matte or semi-gloss finish that suits rustic and handmade aesthetics, highlighting the contrast in visual appeal between the two materials.

Cost Comparison: Porcelain vs Ceramic

Porcelain typically costs more than ceramic due to its denser composition and higher firing temperatures, which enhance durability and water resistance. Ceramic is generally less expensive as it uses softer clay and lower kiln temperatures, making it budget-friendly for various interior applications. Choosing porcelain often entails a higher upfront investment but offers superior long-term value through increased lifespan and reduced maintenance.

Installation and Maintenance Requirements

Porcelain requires less frequent sealing during installation compared to ceramic, making it more durable and resistant to stains and moisture. Its dense composition allows for easier maintenance and cleaning with basic household cleaners, while ceramics often demand grout sealing and more careful upkeep. Installation of porcelain tiles involves precise cutting and professional expertise due to their hardness, whereas ceramic tiles are generally easier to cut and install for DIY projects.

Common Uses in Home and Commercial Settings

Porcelain is commonly used for high-end kitchen countertops, bathroom sinks, and decorative tiles due to its durability and non-porous surface. Ceramic remains popular for everyday items such as dinnerware, wall tiles, and flooring because of its versatility and cost-effectiveness. Commercial settings often favor porcelain for heavy-traffic areas like restaurant floors and public restrooms, while ceramics are preferred for decorative accents and less demanding applications.

Pros and Cons of Porcelain Tiles vs Ceramic Tiles

Porcelain tiles offer higher durability and water resistance compared to ceramic tiles, making them ideal for high-traffic and moisture-prone areas. Ceramic tiles are generally more affordable and easier to cut, benefiting DIY projects and low-traffic spaces. However, porcelain's density and hardness can make installation more labor-intensive and costly.

Which is Better: Porcelain or Ceramic?

Porcelain and ceramic differ primarily in composition, durability, and water absorption rates, with porcelain being denser, less porous, and more resistant to moisture, making it ideal for high-traffic and moisture-prone areas. Porcelain tiles exhibit higher hardness on the Mohs scale and superior resistance to chipping compared to standard ceramic tiles, enhancing longevity and maintenance ease. For applications requiring strength and low absorption, such as bathrooms and outdoor spaces, porcelain outperforms ceramic in both functionality and durability.

Porcelain vs Ceramic Infographic

materialdif.com

materialdif.com