Casting porcelain involves pouring liquid porcelain into molds, allowing for intricate details and thinner, more delicate pieces, whereas pressing porcelain uses mechanical force to shape the material, resulting in denser and more uniform products. Casting offers greater flexibility in design complexity and is ideal for delicate ceramics, while pressing ensures higher strength and consistency suitable for mass production. Both techniques influence the final texture, translucency, and durability of the porcelain items.

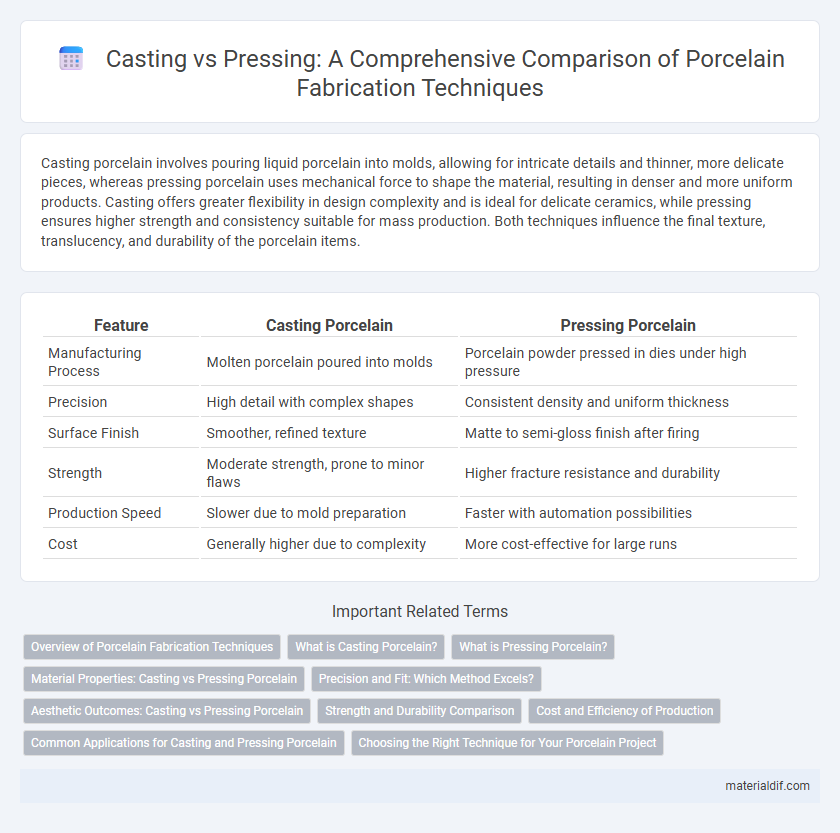

Table of Comparison

| Feature | Casting Porcelain | Pressing Porcelain |

|---|---|---|

| Manufacturing Process | Molten porcelain poured into molds | Porcelain powder pressed in dies under high pressure |

| Precision | High detail with complex shapes | Consistent density and uniform thickness |

| Surface Finish | Smoother, refined texture | Matte to semi-gloss finish after firing |

| Strength | Moderate strength, prone to minor flaws | Higher fracture resistance and durability |

| Production Speed | Slower due to mold preparation | Faster with automation possibilities |

| Cost | Generally higher due to complexity | More cost-effective for large runs |

Overview of Porcelain Fabrication Techniques

Casting porcelain involves pouring liquid porcelain slip into molds, allowing intricate shapes with fine details and uniform thickness to be created efficiently. Pressing porcelain uses mechanical pressure to shape moist porcelain powder within a mold, resulting in denser, more durable pieces ideal for functional ware. Both techniques optimize porcelain fabrication by balancing detail precision, structural integrity, and production scalability.

What is Casting Porcelain?

Casting porcelain involves pouring liquid porcelain slip into a porous mold, allowing the water to be absorbed and leaving a solid layer that forms the shape. This technique ensures finer details and greater uniformity in thin-walled or complex items compared to pressing. The process is ideal for producing delicate porcelain pieces with intricate designs and consistent thickness.

What is Pressing Porcelain?

Pressing porcelain involves shaping dental restorations by applying heat and pressure to porcelain ingots, resulting in dense and highly esthetic crowns or veneers. This technique ensures superior marginal fit and strength compared to traditional methods, making it suitable for both anterior and posterior restorations. Pressed porcelain offers enhanced translucency and color stability, closely mimicking natural tooth enamel.

Material Properties: Casting vs Pressing Porcelain

Casting porcelain offers superior density and strength due to its slow solidification process, which reduces porosity and enhances durability. Pressing porcelain tends to have a more uniform microstructure, resulting in consistent thickness but slightly lower mechanical strength compared to casting. The choice between casting and pressing impacts translucency and wear resistance, with casting porcelain generally exhibiting better esthetic qualities and longevity in dental applications.

Precision and Fit: Which Method Excels?

Casting porcelain offers superior precision and fit due to its ability to create detailed, complex shapes with minimal surface imperfections, ensuring a consistent thickness and accurate margins. Pressing porcelain, while efficient for replicating standardized forms, may result in slight dimensional variations and less intricate detail compared to casting. For dental restorations and high-accuracy applications, casting porcelain remains the preferred method due to its optimal fit and precise adaptation to anatomical contours.

Aesthetic Outcomes: Casting vs Pressing Porcelain

Casting porcelain produces highly detailed and intricate restorations with superior translucency and lifelike aesthetics due to its precise mold adaptation. Pressing porcelain offers consistent density and smooth surface textures, resulting in durable restorations with a slightly less natural appearance compared to casting. The choice between casting and pressing porcelain significantly impacts the final aesthetic, with casting favored for its superior mimicry of natural tooth characteristics.

Strength and Durability Comparison

Casting porcelain offers superior strength due to its denser microstructure and minimal porosity, resulting in enhanced durability for dental restorations. Pressing porcelain, while providing excellent esthetics with a smoother surface finish, tends to be more brittle and prone to microfractures under heavy occlusal forces. Clinical studies confirm that casting porcelain withstands higher flexural stresses, making it more suitable for long-term applications where mechanical resilience is critical.

Cost and Efficiency of Production

Casting porcelain offers greater efficiency for complex shapes, reducing material waste and labor costs, making it ideal for low to medium volume production despite higher initial setup expenses. Pressing porcelain accelerates production cycles with lower per-unit cost in mass manufacturing, but is less flexible for intricate designs and may result in higher material waste. Manufacturers must weigh casting's cost-effectiveness in customization against pressing's efficiency in large-scale output when optimizing production strategy.

Common Applications for Casting and Pressing Porcelain

Casting porcelain is commonly used in creating intricate dental restorations such as crowns and bridges due to its ability to form precise and detailed shapes. Pressing porcelain finds wide application in producing dental veneers and inlays where strength and aesthetic appeal are critical. Both methods optimize the surface texture and translucency to mimic natural teeth effectively.

Choosing the Right Technique for Your Porcelain Project

Casting porcelain offers superior detail and complex shapes by pouring liquid slip into molds, ideal for intricate designs and thin-walled pieces. Pressing porcelain involves compacting clay into a mold, providing density and strength, making it suitable for durable, solid forms. Selecting the right technique depends on project requirements for detail versus durability, with casting favored for artistic finesse and pressing preferred for robust, functional items.

Casting Porcelain vs Pressing Porcelain Infographic

materialdif.com

materialdif.com