Porcelain enamel is a glass-like, durable coating fused onto metal surfaces through high-temperature firing, providing excellent resistance to corrosion and scratches. Porcelain coating, while similar in appearance, typically refers to a thinner, polymer-based layer applied to protect and enhance surfaces but lacks the same heat resistance and longevity as enamel. Choosing between porcelain enamel and porcelain coating depends on the specific application demands, such as durability, appearance, and exposure to heat or harsh environments.

Table of Comparison

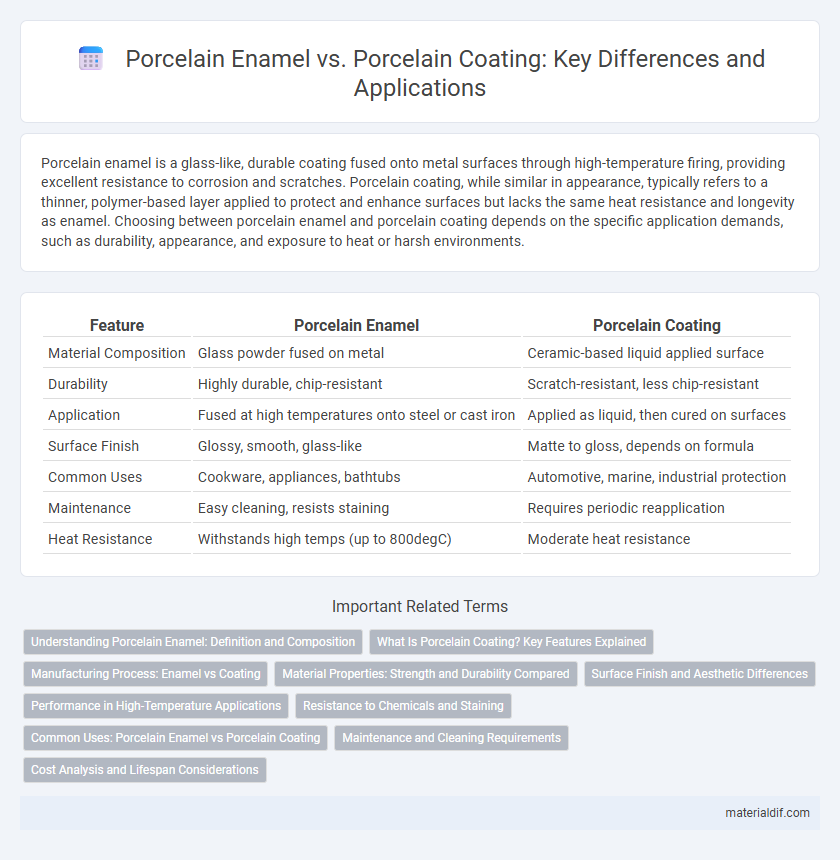

| Feature | Porcelain Enamel | Porcelain Coating |

|---|---|---|

| Material Composition | Glass powder fused on metal | Ceramic-based liquid applied surface |

| Durability | Highly durable, chip-resistant | Scratch-resistant, less chip-resistant |

| Application | Fused at high temperatures onto steel or cast iron | Applied as liquid, then cured on surfaces |

| Surface Finish | Glossy, smooth, glass-like | Matte to gloss, depends on formula |

| Common Uses | Cookware, appliances, bathtubs | Automotive, marine, industrial protection |

| Maintenance | Easy cleaning, resists staining | Requires periodic reapplication |

| Heat Resistance | Withstands high temps (up to 800degC) | Moderate heat resistance |

Understanding Porcelain Enamel: Definition and Composition

Porcelain enamel is a durable glass coating fused to metal at high temperatures, composed primarily of powdered glass, minerals, and pigments that create a smooth, glossy surface. This coating provides superior resistance to corrosion, scratches, and heat, making it ideal for cookware, appliances, and decorative items. Unlike porcelain coatings, which are often polymer-based and applied in thinner layers, porcelain enamel forms a thick, protective, and long-lasting barrier bonded directly to the substrate.

What Is Porcelain Coating? Key Features Explained

Porcelain coating is a durable, glass-like protective layer applied to surfaces such as car paint or cookware, designed to repel dirt, water, and corrosion while enhancing gloss and longevity. Unlike porcelain enamel, which involves fusing powdered glass to metal through high-temperature firing, porcelain coating is a liquid polymer that cures to form a hard, protective shell. Key features include excellent resistance to scratches, UV rays, chemical stains, and easy maintenance, making it ideal for both aesthetic and functional surface protection.

Manufacturing Process: Enamel vs Coating

Porcelain enamel involves fusing a powdered glass mixture onto metal at temperatures exceeding 1400degF, creating a durable, glass-like surface through a vitrification process. Porcelain coating, however, refers to a sprayed polymer-based layer applied at lower temperatures, forming a thin, protective barrier without the intense heating required for enamel. The manufacturing process of enamel ensures greater hardness and resistance to corrosion compared to the flexible yet less heat-resistant porcelain coating.

Material Properties: Strength and Durability Compared

Porcelain enamel is created by fusing powdered glass to a substrate at high temperatures, resulting in a hard, glossy surface renowned for exceptional strength and resistance to corrosion, scratches, and chemical damage. Porcelain coating, often a thinner application of glass-like material, provides durable protection but typically lacks the same thickness and impact resistance as traditional porcelain enamel. Both materials offer excellent durability, but porcelain enamel's fused glass layer delivers superior long-term performance in harsh environments.

Surface Finish and Aesthetic Differences

Porcelain enamel features a thick, glass-like coating fused at high temperatures, providing a smooth, glossy surface finish that is highly durable and resistant to scratches and stains. Porcelain coating, often thinner and applied via spray or brush methods, offers more flexibility in texture and can vary from matte to glossy finishes, but it is generally less robust and more prone to chipping over time. Aesthetically, porcelain enamel delivers a uniform, vibrant color with exceptional shine, while porcelain coatings enable customizable finishes that may lack the consistent brilliance of enamel but allow for more diverse design options.

Performance in High-Temperature Applications

Porcelain enamel exhibits exceptional performance in high-temperature applications due to its durable, glass-like surface that resists heat up to 1,200degF (650degC) without degrading or cracking. Porcelain coating, while offering protective benefits, generally withstands lower temperature ranges, often up to 800degF (427degC), making it less suitable for extreme heat environments. The superior thermal resistance and chemical inertness of porcelain enamel make it the preferred choice for industrial furnaces, cookware, and stoves where long-term heat exposure is critical.

Resistance to Chemicals and Staining

Porcelain enamel offers superior resistance to chemicals and staining due to its glass-like, non-porous surface fused to metal at high temperatures, creating a durable barrier against corrosion and discoloration. Porcelain coating, often a synthetic polymer-based layer applied on surfaces, provides moderate chemical resistance but is more prone to staining and wear over time compared to porcelain enamel. The inherent hardness and impervious nature of porcelain enamel make it the preferred choice for environments exposed to harsh chemicals and persistent staining agents.

Common Uses: Porcelain Enamel vs Porcelain Coating

Porcelain enamel is commonly used for coating cookware, bathtubs, and appliances due to its durable, glassy surface that resists scratching and staining. Porcelain coating, often applied as a protective layer on automotive parts and industrial equipment, provides corrosion resistance and a smooth, attractive finish. Both materials enhance durability and aesthetics but serve different industries based on their specific properties and application methods.

Maintenance and Cleaning Requirements

Porcelain enamel features a durable glass-like coating fused to metal, offering high resistance to staining, scratching, and corrosion, making it easy to clean with mild detergents and non-abrasive sponges. Porcelain coating, often a thinner, polymer-based layer, requires more delicate maintenance to prevent damage, demanding gentle cleaning agents and avoiding harsh scrubbing or chemical exposure. Regular upkeep for porcelain enamel is less intensive, while porcelain coating maintenance depends heavily on careful handling to preserve its protective and aesthetic qualities.

Cost Analysis and Lifespan Considerations

Porcelain enamel typically involves fusing powdered glass to metal at high temperatures, resulting in a durable, chip-resistant surface with a lifespan of 20 to 30 years, but it comes with higher upfront costs due to the complex manufacturing process. Porcelain coatings are thinner, polymer-based layers applied to surfaces offering a more affordable option but generally last 5 to 10 years before requiring reapplication or replacement. Cost analysis favors porcelain coatings for budget-conscious projects, while lifespan considerations make porcelain enamel ideal for long-term durability despite its premium price.

Porcelain Enamel vs Porcelain Coating Infographic

materialdif.com

materialdif.com