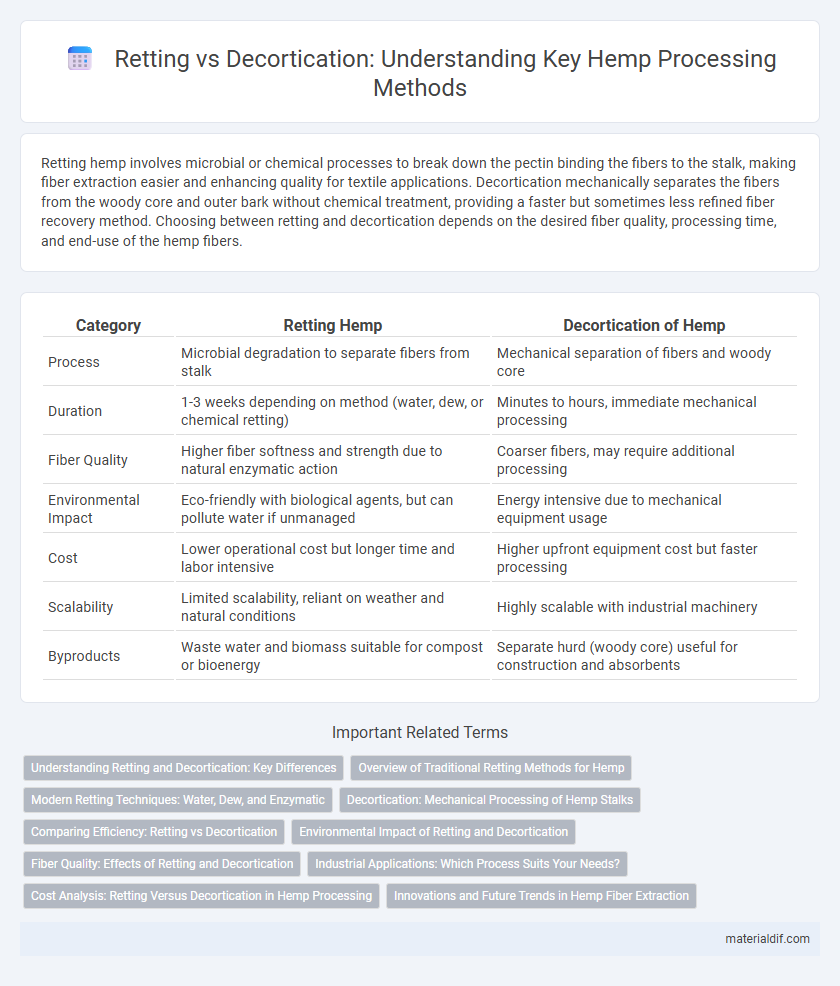

Retting hemp involves microbial or chemical processes to break down the pectin binding the fibers to the stalk, making fiber extraction easier and enhancing quality for textile applications. Decortication mechanically separates the fibers from the woody core and outer bark without chemical treatment, providing a faster but sometimes less refined fiber recovery method. Choosing between retting and decortication depends on the desired fiber quality, processing time, and end-use of the hemp fibers.

Table of Comparison

| Category | Retting Hemp | Decortication of Hemp |

|---|---|---|

| Process | Microbial degradation to separate fibers from stalk | Mechanical separation of fibers and woody core |

| Duration | 1-3 weeks depending on method (water, dew, or chemical retting) | Minutes to hours, immediate mechanical processing |

| Fiber Quality | Higher fiber softness and strength due to natural enzymatic action | Coarser fibers, may require additional processing |

| Environmental Impact | Eco-friendly with biological agents, but can pollute water if unmanaged | Energy intensive due to mechanical equipment usage |

| Cost | Lower operational cost but longer time and labor intensive | Higher upfront equipment cost but faster processing |

| Scalability | Limited scalability, reliant on weather and natural conditions | Highly scalable with industrial machinery |

| Byproducts | Waste water and biomass suitable for compost or bioenergy | Separate hurd (woody core) useful for construction and absorbents |

Understanding Retting and Decortication: Key Differences

Retting hemp involves using moisture and microbial action to break down the pectin that binds fibers to the stalk, facilitating easier fiber separation but requiring careful timing to prevent fiber damage. Decortication mechanically separates the bast fibers from the woody core without relying on microbial activity, offering faster processing and more consistent fiber quality. Understanding these key differences is crucial for selecting the appropriate method based on desired fiber characteristics and production scale.

Overview of Traditional Retting Methods for Hemp

Traditional retting methods for hemp involve controlled microbial decomposition to separate bast fibers from the stalk. Water retting, often performed in ponds or streams, relies on anaerobic bacteria to break down pectin surrounding the fibers, typically taking 7 to 14 days. Dew retting uses natural moisture and environmental conditions, allowing fungi and bacteria to degrade the non-fibrous material over several weeks in the field, with outcomes influenced by temperature and humidity.

Modern Retting Techniques: Water, Dew, and Enzymatic

Modern retting techniques for hemp include water retting, dew retting, and enzymatic retting, each optimizing fiber extraction by targeting pectin degradation. Water retting immerses hemp stalks in controlled aquatic environments, accelerating microbial action for thorough fiber separation. Enzymatic retting employs tailored pectinase enzymes, offering a rapid, eco-friendly alternative that enhances fiber quality while reducing environmental impact.

Decortication: Mechanical Processing of Hemp Stalks

Decortication of hemp involves mechanical processing of hemp stalks to separate fibers from the woody core, enhancing fiber quality and reducing processing time compared to traditional retting methods. Advanced decorticators utilize crushing, breaking, and scutching techniques to efficiently extract long bast fibers suitable for textiles, composites, and bioplastics. This method supports sustainable hemp production by minimizing water usage and environmental impact while maximizing fiber yield and consistency.

Comparing Efficiency: Retting vs Decortication

Retting hemp involves microbial or chemical processes that break down pectin binding fibers to the stalk, enabling fiber extraction but requiring several days to weeks and controlled environmental conditions. Decortication mechanically separates hemp stalks into fiber and woody core rapidly, often within minutes, offering higher throughput and consistency with less dependency on weather or microbial activity. Comparing efficiency, decortication provides faster processing, higher yield of long fibers, and industrial scalability, whereas retting yields finer fibers but at the cost of longer processing times and greater variability.

Environmental Impact of Retting and Decortication

Retting hemp involves microbial action to break down pectins, which can release water pollutants and generate unpleasant odors, raising concerns about river and soil contamination if not properly managed. Decortication mechanically separates hemp fibers without water usage, significantly reducing water pollution but requiring high energy input that may increase carbon emissions. Choosing between retting and decortication depends on balancing water pollution risks against energy consumption and greenhouse gas emissions in hemp fiber processing.

Fiber Quality: Effects of Retting and Decortication

Retting enhances hemp fiber quality by facilitating the natural separation of bast fibers, resulting in smoother, finer, and stronger fibers ideal for textiles. Decortication mechanically strips the hemp stalk, yielding coarser fibers that may contain impurities but supports higher processing speed and bulk production. The choice between retting and decortication significantly influences fiber tensile strength, fineness, and usability in composite materials versus fabric manufacturing.

Industrial Applications: Which Process Suits Your Needs?

Retting hemp involves microbial or chemical treatments to break down pectin, facilitating fiber separation, ideal for applications requiring long, strong fibers such as textiles and rope manufacturing. Decortication mechanically separates bast fibers from the woody core, offering efficiency and consistency, making it suitable for industrial uses like biocomposites, insulation, and paper production. Selecting between retting and decortication depends on the desired fiber quality, production scale, and end-use industry requirements.

Cost Analysis: Retting Versus Decortication in Hemp Processing

Retting hemp involves soaking stalks to break down pectins and separate fibers, typically incurring lower initial equipment costs but higher water usage and longer processing time. Decortication uses mechanical separation to extract fibers quickly, leading to higher capital investment and maintenance expenses but reduced labor and water costs. Cost analysis reveals retting is more economical for small-scale operations, while decortication suits large-scale production due to efficiency and scalability.

Innovations and Future Trends in Hemp Fiber Extraction

Innovations in hemp fiber extraction focus on enhancing retting and decortication processes through enzymatic treatments and advanced mechanical technologies that improve fiber quality and reduce environmental impact. Future trends emphasize sustainable, energy-efficient decortication methods integrated with precision monitoring systems to optimize fiber yield and consistency. Hybrid approaches combining biological retting with automated decortication promise breakthroughs in scalability and cost-effectiveness for industrial hemp applications.

Retting hemp vs Decortication of hemp Infographic

materialdif.com

materialdif.com