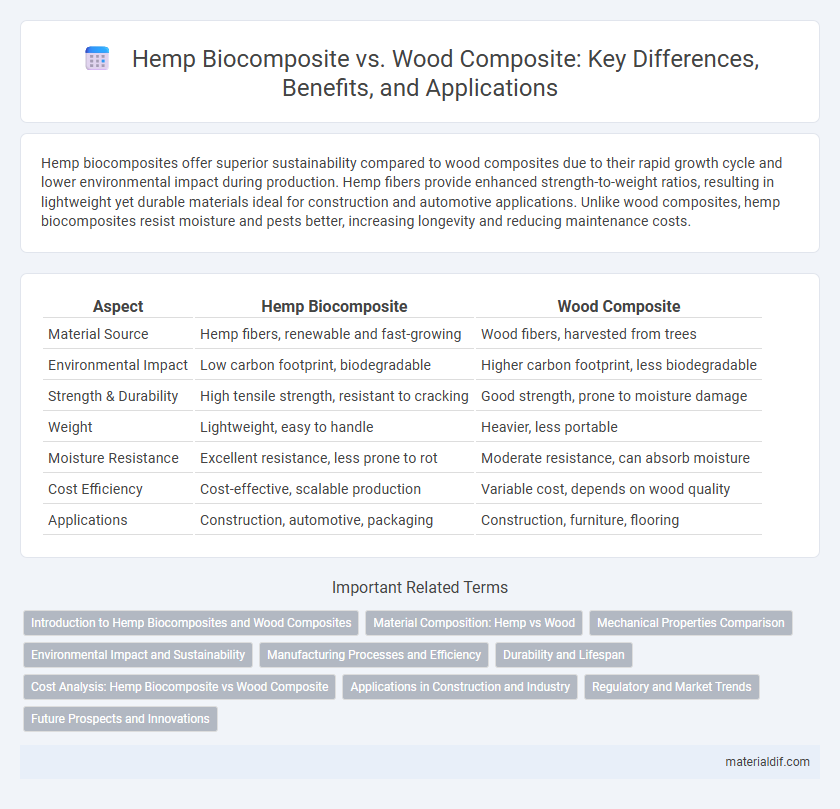

Hemp biocomposites offer superior sustainability compared to wood composites due to their rapid growth cycle and lower environmental impact during production. Hemp fibers provide enhanced strength-to-weight ratios, resulting in lightweight yet durable materials ideal for construction and automotive applications. Unlike wood composites, hemp biocomposites resist moisture and pests better, increasing longevity and reducing maintenance costs.

Table of Comparison

| Aspect | Hemp Biocomposite | Wood Composite |

|---|---|---|

| Material Source | Hemp fibers, renewable and fast-growing | Wood fibers, harvested from trees |

| Environmental Impact | Low carbon footprint, biodegradable | Higher carbon footprint, less biodegradable |

| Strength & Durability | High tensile strength, resistant to cracking | Good strength, prone to moisture damage |

| Weight | Lightweight, easy to handle | Heavier, less portable |

| Moisture Resistance | Excellent resistance, less prone to rot | Moderate resistance, can absorb moisture |

| Cost Efficiency | Cost-effective, scalable production | Variable cost, depends on wood quality |

| Applications | Construction, automotive, packaging | Construction, furniture, flooring |

Introduction to Hemp Biocomposites and Wood Composites

Hemp biocomposites are sustainable materials made by combining hemp fibers with biodegradable polymers, offering high strength-to-weight ratios and enhanced environmental benefits compared to traditional composites. Wood composites consist of wood particles or fibers bonded with resins, widely used in construction and furniture due to their durability and cost-effectiveness but often involve non-renewable adhesives. The unique cellular structure of hemp fibers provides superior mechanical properties and faster growth cycles, positioning hemp biocomposites as eco-friendly alternatives to conventional wood composites in various industrial applications.

Material Composition: Hemp vs Wood

Hemp biocomposites consist primarily of hemp fibers combined with natural or synthetic binders, offering high tensile strength and lightweight properties. Wood composites are made from wood fibers or particles bonded with adhesives, which can introduce formaldehyde and other volatile organic compounds. The cellulose content in hemp fibers is higher than that of wood, enhancing durability and resistance to moisture in hemp biocomposites compared to wood composites.

Mechanical Properties Comparison

Hemp biocomposites exhibit superior tensile strength and impact resistance compared to traditional wood composites, making them ideal for lightweight structural applications. The high cellulose content in hemp fibers enhances stiffness and durability, while wood composites often show higher moisture absorption leading to reduced mechanical performance over time. Hemp biocomposites also offer better flexural modulus and improved dimensional stability under varying environmental conditions.

Environmental Impact and Sustainability

Hemp biocomposites demonstrate significantly lower carbon footprints compared to wood composites due to hemp's rapid growth cycle and high CO2 absorption capacity. The biodegradability and non-toxic nature of hemp fibers contribute to reduced environmental pollution and enhanced soil health during production. Sustainable cultivation practices of hemp reduce deforestation risks inherent in wood composite manufacturing, making hemp biocomposites a more eco-friendly alternative.

Manufacturing Processes and Efficiency

Hemp biocomposites utilize shorter processing times and lower energy consumption compared to wood composites due to the natural fiber's rapid growth and ease of chemical extraction. Manufacturing hemp biocomposites involves eco-friendly techniques such as steam explosion and enzymatic retting, which enhance fiber-matrix adhesion and reduce harmful emissions. In contrast, wood composites require extensive debarking and chemical treatments, resulting in higher production costs and longer cycle times.

Durability and Lifespan

Hemp biocomposites exhibit superior durability compared to wood composites due to their resistance to moisture, fungal decay, and insect damage, resulting in an extended lifespan. The natural fiber reinforcement in hemp composites enhances mechanical strength and dimensional stability, making them less prone to warping and cracking. These properties contribute to hemp biocomposites' increasing use in construction and automotive industries where long-lasting, sustainable materials are critical.

Cost Analysis: Hemp Biocomposite vs Wood Composite

Hemp biocomposites often present a lower overall cost due to the rapid growth cycle and high yield of hemp fibers, reducing raw material expenses compared to wood composites. Processing hemp fibers requires less energy and chemicals, further decreasing production costs in comparison to traditional wood composite manufacturing. Market demand and supply fluctuations influence pricing, but hemp biocomposites offer a cost-effective alternative with competitive durability and eco-friendly benefits.

Applications in Construction and Industry

Hemp biocomposites offer superior thermal insulation and moisture resistance compared to traditional wood composites, making them ideal for sustainable building materials such as panels, insulation boards, and structural components in construction. Their lightweight properties and high tensile strength enhance durability and reduce transportation costs in industrial applications, including automotive parts and packaging. The renewable nature of hemp fibers also supports eco-friendly manufacturing processes, positioning hemp biocomposites as a greener alternative to conventional wood-based composites.

Regulatory and Market Trends

Hemp biocomposites are gaining regulatory support due to increasing sustainability mandates and favorable agricultural policies promoting industrial hemp cultivation. Market trends show a rising demand for eco-friendly materials in construction and automotive sectors, where hemp composites offer superior biodegradability and carbon sequestration compared to traditional wood composites. Regulatory frameworks in North America and Europe increasingly incentivize the use of hemp-based materials to meet circular economy goals and reduce reliance on deforestation-linked wood products.

Future Prospects and Innovations

Hemp biocomposites offer superior sustainability and faster renewable cycles compared to traditional wood composites, making them a promising material for future green construction and manufacturing. Innovations in hemp fiber extraction and resin formulation are enhancing durability and mechanical properties, enabling broader industrial applications. Research into nano-engineering hemp biocomposites is poised to revolutionize lightweight, high-strength materials, driving widespread adoption in automotive and aerospace sectors.

Hemp biocomposite vs Wood composite Infographic

materialdif.com

materialdif.com