Hemp paper offers superior durability and requires fewer chemicals during production compared to wood pulp paper, making it an eco-friendlier alternative. Its fibers are longer and stronger, resulting in a product that resists yellowing and deterioration over time. Choosing hemp paper reduces deforestation and supports sustainable agriculture by utilizing a rapidly renewable resource.

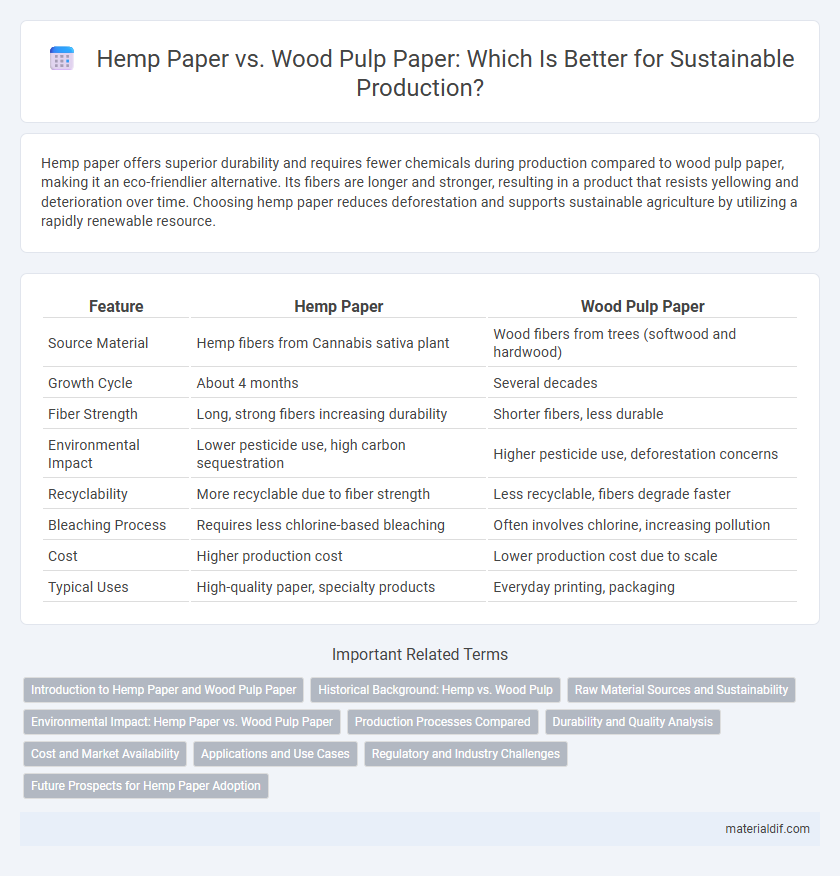

Table of Comparison

| Feature | Hemp Paper | Wood Pulp Paper |

|---|---|---|

| Source Material | Hemp fibers from Cannabis sativa plant | Wood fibers from trees (softwood and hardwood) |

| Growth Cycle | About 4 months | Several decades |

| Fiber Strength | Long, strong fibers increasing durability | Shorter fibers, less durable |

| Environmental Impact | Lower pesticide use, high carbon sequestration | Higher pesticide use, deforestation concerns |

| Recyclability | More recyclable due to fiber strength | Less recyclable, fibers degrade faster |

| Bleaching Process | Requires less chlorine-based bleaching | Often involves chlorine, increasing pollution |

| Cost | Higher production cost | Lower production cost due to scale |

| Typical Uses | High-quality paper, specialty products | Everyday printing, packaging |

Introduction to Hemp Paper and Wood Pulp Paper

Hemp paper, derived from the fibers of the Cannabis sativa plant, offers a sustainable and eco-friendly alternative to conventional wood pulp paper, which is made primarily from timber trees such as pine and fir. Hemp fibers are longer and stronger, resulting in paper that is more durable and resistant to yellowing compared to wood pulp paper that relies on intensive chemical processing and deforestation. The production of hemp paper consumes less water and energy, contributing to its rising popularity in sustainable manufacturing and environmental conservation efforts.

Historical Background: Hemp vs. Wood Pulp

Hemp paper dates back to ancient China over 2,000 years ago and was widely used before the 19th century, while wood pulp paper emerged in the mid-1800s with industrialization. Historically, hemp fibers offered superior durability and required fewer chemicals during processing compared to wood pulp, which involves intensive bleaching and deforestation. The revival of hemp paper reflects growing environmental concerns and the demand for sustainable alternatives to traditional wood pulp paper.

Raw Material Sources and Sustainability

Hemp paper is derived from the fibrous stalks of the Cannabis sativa plant, which grow rapidly and require fewer pesticides and herbicides compared to trees used in wood pulp paper production. Unlike wood pulp paper, which comes from slow-growing trees that contribute to deforestation, hemp paper offers a renewable raw material source with a significantly lower environmental footprint. This sustainable advantage in resource efficiency and biodegradability makes hemp paper a more eco-friendly alternative to traditional wood pulp paper.

Environmental Impact: Hemp Paper vs. Wood Pulp Paper

Hemp paper has a significantly lower environmental impact than wood pulp paper due to its rapid growth cycle and higher yield per acre, requiring fewer pesticides and less water. Hemp fibers are stronger and more durable, allowing recycling up to eight times compared to three for wood pulp paper, which reduces deforestation and landfill waste. The production of hemp paper produces fewer greenhouse gas emissions and less chemical pollution, making it a more sustainable alternative for eco-friendly paper products.

Production Processes Compared

Hemp paper production involves processing bast fibers, which are longer and stronger than wood fibers, resulting in a durable and high-quality pulp with fewer chemicals and less energy consumption. Wood pulp paper manufacturing requires extensive mechanical and chemical treatments, including bleaching and lignin removal, leading to higher environmental impact and resource use. The hemp process enables faster growth cycles and sustainable harvesting, making it a more eco-friendly alternative to conventional wood pulp paper production.

Durability and Quality Analysis

Hemp paper offers superior durability compared to wood pulp paper due to its longer, stronger fibers that resist tearing and yellowing over time. The natural lignin content in wood pulp paper promotes quicker degradation and brittleness, reducing its lifespan. Hemp's higher cellulose content results in a smoother, more resilient paper quality ideal for archival and high-quality printing purposes.

Cost and Market Availability

Hemp paper is generally more expensive than wood pulp paper due to higher production costs and limited industrial-scale processing facilities. Wood pulp paper dominates the market with widespread availability and well-established supply chains, making it more cost-effective for mass production. Despite the higher initial cost, hemp paper offers potential long-term economic benefits through sustainability and durability, attracting niche markets focused on eco-friendly products.

Applications and Use Cases

Hemp paper is widely used in packaging, stationery, and specialty printing due to its durability, high tensile strength, and eco-friendly properties, making it ideal for archival documents and sustainable products. Wood pulp paper dominates in mass-market applications such as newspapers, books, and tissue products because of its lower cost and established manufacturing infrastructure. Industrial sectors increasingly favor hemp paper for recycled and biodegradable applications, aligning with growing environmental regulations and consumer demand for green alternatives.

Regulatory and Industry Challenges

Hemp paper faces significant regulatory challenges due to its association with cannabis, requiring extensive compliance with legal frameworks that vary by region, unlike wood pulp paper which benefits from established regulatory standards. The hemp paper industry struggles with limited processing infrastructure and higher production costs compared to the mature wood pulp industry, hindering widespread adoption. Environmental regulations increasingly favor sustainable materials, presenting both an opportunity and ongoing challenges for hemp paper manufacturers to meet stringent quality and safety benchmarks.

Future Prospects for Hemp Paper Adoption

Hemp paper offers significant environmental advantages over wood pulp paper, including faster growth cycles, higher fiber yield per acre, and reduced chemical processing, making it a sustainable alternative for the paper industry. Advancements in hemp cultivation and processing technologies are driving increased feasibility and cost-effectiveness, encouraging major manufacturers to explore hemp as a raw material. Market trends indicate a growing demand for eco-friendly products, positioning hemp paper as a promising solution to reduce deforestation and carbon footprints in the future.

hemp paper vs wood pulp paper Infographic

materialdif.com

materialdif.com