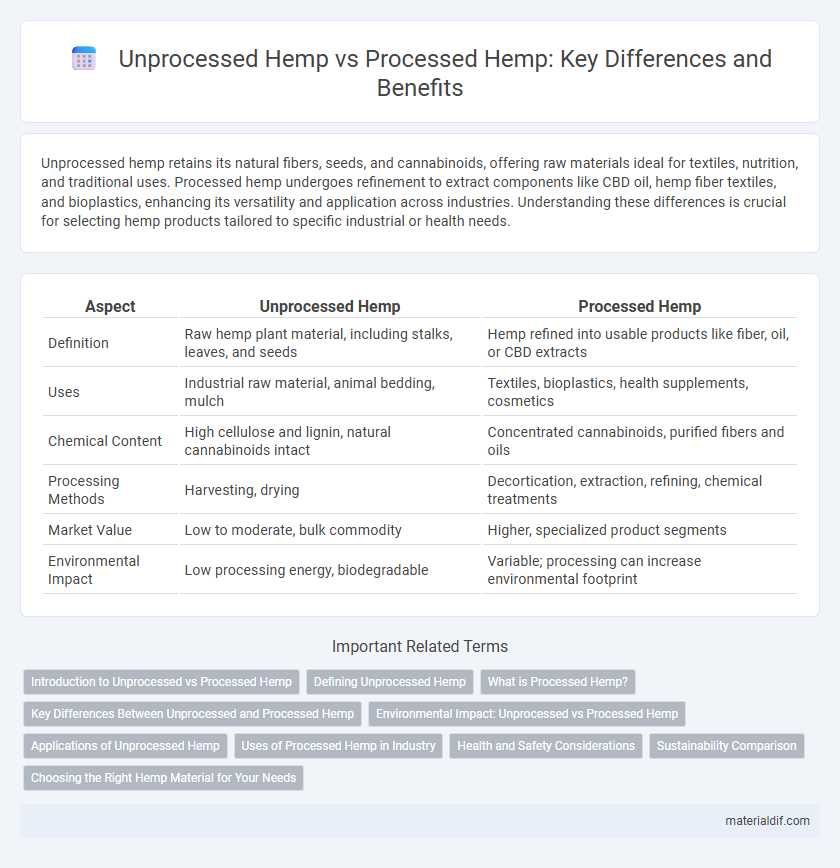

Unprocessed hemp retains its natural fibers, seeds, and cannabinoids, offering raw materials ideal for textiles, nutrition, and traditional uses. Processed hemp undergoes refinement to extract components like CBD oil, hemp fiber textiles, and bioplastics, enhancing its versatility and application across industries. Understanding these differences is crucial for selecting hemp products tailored to specific industrial or health needs.

Table of Comparison

| Aspect | Unprocessed Hemp | Processed Hemp |

|---|---|---|

| Definition | Raw hemp plant material, including stalks, leaves, and seeds | Hemp refined into usable products like fiber, oil, or CBD extracts |

| Uses | Industrial raw material, animal bedding, mulch | Textiles, bioplastics, health supplements, cosmetics |

| Chemical Content | High cellulose and lignin, natural cannabinoids intact | Concentrated cannabinoids, purified fibers and oils |

| Processing Methods | Harvesting, drying | Decortication, extraction, refining, chemical treatments |

| Market Value | Low to moderate, bulk commodity | Higher, specialized product segments |

| Environmental Impact | Low processing energy, biodegradable | Variable; processing can increase environmental footprint |

Introduction to Unprocessed vs Processed Hemp

Unprocessed hemp consists of raw stalks, seeds, and leaves harvested directly from the plant, retaining natural fibers and cannabinoids in their original form. Processed hemp undergoes treatments such as decortication, extraction, and refining to produce derivatives like hemp fiber, CBD oil, and hemp protein isolates. The distinction between unprocessed and processed hemp is crucial for determining applications in textiles, wellness products, and industrial materials.

Defining Unprocessed Hemp

Unprocessed hemp consists of raw stalks, leaves, and seeds harvested directly from the plant without undergoing any refining or extraction methods. This form retains all natural fibers, cannabinoids, and bioactive compounds in their original state, making it essential for applications requiring full-spectrum material. Unprocessed hemp is primarily utilized in textiles, animal feed, and traditional industrial uses before further processing converts it into concentrates or finished products.

What is Processed Hemp?

Processed hemp refers to hemp fibers and materials that have undergone treatments such as retting, decortication, and refining to extract usable components like fibers, oils, and cannabinoids. This transformation enhances the hemp's properties for specific applications in textiles, construction, food products, and wellness supplements. Processed hemp products include hemp fiber textiles, hemp seed oil, CBD extracts, and hempcrete building materials.

Key Differences Between Unprocessed and Processed Hemp

Unprocessed hemp consists of raw stalks, seeds, and leaves harvested directly from the plant, retaining natural fibers, cannabinoids, and nutrients in their original state. Processed hemp undergoes techniques such as decortication, extraction, and refining to produce products like hemp fiber, oil, CBD extract, and hemp-based textiles with enhanced purity and specific functional properties. Key differences include the chemical composition, usability, and industrial applications, where unprocessed hemp excels in agricultural and mulching uses, while processed hemp serves in pharmaceuticals, food supplements, and sustainable manufacturing.

Environmental Impact: Unprocessed vs Processed Hemp

Unprocessed hemp requires minimal energy and water inputs, resulting in a lower carbon footprint and reduced environmental degradation compared to processed hemp. Processing hemp into products like fibers, oils, or textiles involves chemical treatments and mechanical operations that increase water consumption and generate waste byproducts. Choosing unprocessed hemp supports sustainable agriculture by minimizing pollution and conserving natural resources.

Applications of Unprocessed Hemp

Unprocessed hemp, including raw stalks, leaves, and seeds, serves as a versatile resource in agriculture, textiles, and construction industries. Its fibrous stalks are primarily used for manufacturing eco-friendly textiles and biocomposites, while seeds provide nutrition and oil extraction benefits. Unprocessed hemp's applications also extend to animal bedding and biodegradable packaging, highlighting its sustainability and minimal processing requirements.

Uses of Processed Hemp in Industry

Processed hemp is widely utilized in industries such as textiles, construction, and bioplastics, offering sustainable alternatives to traditional materials. Its fibers are refined for fabric production, while hemp hurds serve as key components in eco-friendly building products like hempcrete. Furthermore, processed hemp seeds and oils find applications in food, cosmetics, and pharmaceuticals, highlighting its versatility across multiple sectors.

Health and Safety Considerations

Unprocessed hemp contains natural fibers and compounds that may harbor dirt, pesticides, or microbial contaminants, requiring thorough cleaning to ensure safety for consumption or topical use. Processed hemp undergoes extraction or refinement to isolate cannabinoids like CBD or fibers, significantly reducing potentially harmful substances and standardizing product quality. Consumers should prioritize products tested for contaminants and produced following industry safety regulations to minimize health risks.

Sustainability Comparison

Unprocessed hemp requires minimal energy input and chemical use, making it a highly sustainable raw material with low environmental impact. Processed hemp products often involve energy-intensive methods such as decortication, fiber separation, and chemical treatments, which can increase carbon footprint and water consumption. Choosing unprocessed hemp supports soil health, reduces pollution, and conserves natural resources compared to processed variants.

Choosing the Right Hemp Material for Your Needs

Unprocessed hemp retains its natural fibers and nutrients, making it ideal for applications like textiles, paper, and certain health products where organic integrity is crucial. Processed hemp undergoes methods such as decortication, retting, or chemical extraction to isolate fibers, oils, or CBD, enhancing usability in industries like construction, cosmetics, and pharmaceuticals. Selecting the right hemp material depends on your end-use requirements, balancing purity, strength, and bioactive content to optimize performance and sustainability.

Unprocessed Hemp vs Processed Hemp Infographic

materialdif.com

materialdif.com