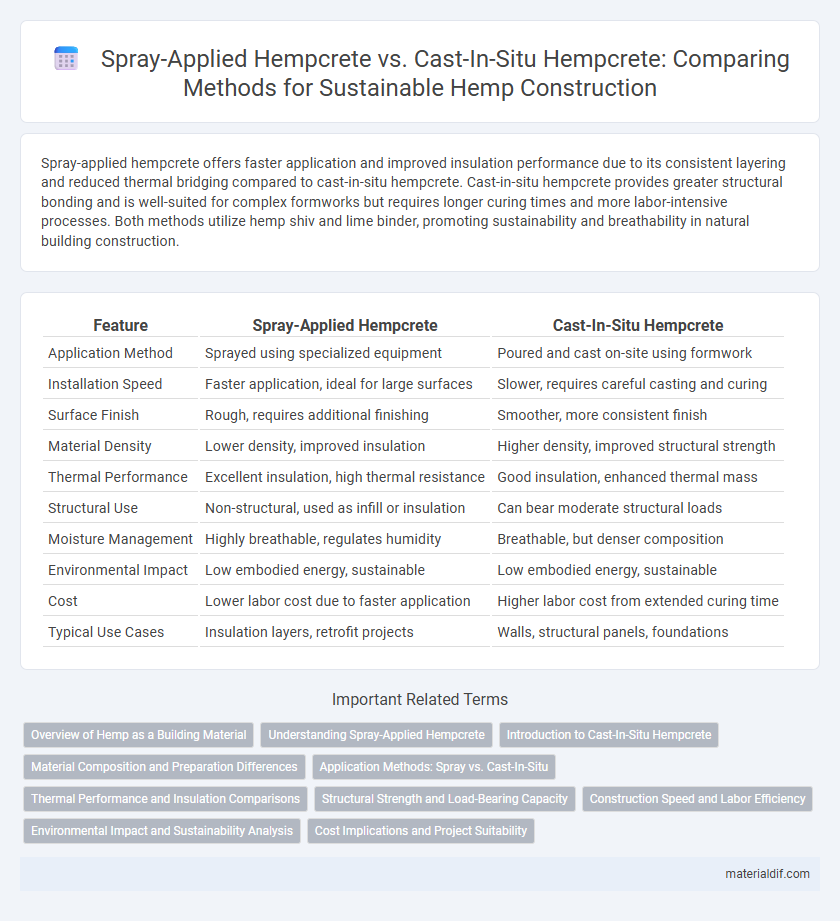

Spray-applied hempcrete offers faster application and improved insulation performance due to its consistent layering and reduced thermal bridging compared to cast-in-situ hempcrete. Cast-in-situ hempcrete provides greater structural bonding and is well-suited for complex formworks but requires longer curing times and more labor-intensive processes. Both methods utilize hemp shiv and lime binder, promoting sustainability and breathability in natural building construction.

Table of Comparison

| Feature | Spray-Applied Hempcrete | Cast-In-Situ Hempcrete |

|---|---|---|

| Application Method | Sprayed using specialized equipment | Poured and cast on-site using formwork |

| Installation Speed | Faster application, ideal for large surfaces | Slower, requires careful casting and curing |

| Surface Finish | Rough, requires additional finishing | Smoother, more consistent finish |

| Material Density | Lower density, improved insulation | Higher density, improved structural strength |

| Thermal Performance | Excellent insulation, high thermal resistance | Good insulation, enhanced thermal mass |

| Structural Use | Non-structural, used as infill or insulation | Can bear moderate structural loads |

| Moisture Management | Highly breathable, regulates humidity | Breathable, but denser composition |

| Environmental Impact | Low embodied energy, sustainable | Low embodied energy, sustainable |

| Cost | Lower labor cost due to faster application | Higher labor cost from extended curing time |

| Typical Use Cases | Insulation layers, retrofit projects | Walls, structural panels, foundations |

Overview of Hemp as a Building Material

Hemp as a building material offers exceptional thermal insulation, breathability, and sustainability due to its rapid growth and low carbon footprint. Spray-applied hempcrete provides flexibility in application and enhanced adhesion on complex surfaces, while cast-in-situ hempcrete ensures structural uniformity and superior compressive strength through formwork casting. Both methods utilize hemp's natural properties to create energy-efficient, moisture-regulating walls that contribute to greener construction practices.

Understanding Spray-Applied Hempcrete

Spray-applied hempcrete offers a faster and more flexible application method compared to cast-in-situ hempcrete, allowing for efficient spraying onto varied surfaces and complex shapes. This method enhances adhesion and reduces labor intensity while maintaining the thermal insulation and breathability properties inherent to hempcrete. Understanding spray-applied hempcrete is essential for optimizing building performance and sustainability in eco-friendly construction projects.

Introduction to Cast-In-Situ Hempcrete

Cast-In-Situ Hempcrete is a bio-composite building material created by mixing hemp shiv, lime-based binder, and water, then pouring the mixture directly into formwork to cure on-site. This method ensures a monolithic structure with excellent thermal insulation, moisture regulation, and carbon sequestration properties, making it highly sustainable for eco-friendly construction. Compared to Spray-Applied Hempcrete, Cast-In-Situ offers enhanced structural integrity and customization for complex architectural designs.

Material Composition and Preparation Differences

Spray-applied hempcrete utilizes a wetter, more fluid mixture with higher water content and added additives to enable spraying through specialized equipment, whereas cast-in-situ hempcrete employs a drier, stiffer mix optimized for manual or formwork casting. The spray application requires precise calibration of binder ratios, typically lime-based, and a reduced aggregate size to prevent clogging, while cast-in-situ hempcrete mixtures allow for coarser hemp shiv and less stringent fluidity. Preparation for spray-applied hempcrete involves specialized pump systems and no formwork, contrasting with cast-in-situ hempcrete which relies on traditional molds and manual tamping for compaction.

Application Methods: Spray vs. Cast-In-Situ

Spray-applied hempcrete enables faster and more uniform coverage by atomizing the hemp-lime mixture directly onto surfaces, reducing labor time and minimizing waste. Cast-in-situ hempcrete involves pouring the mixture into molds or formwork on site, allowing for precise shaping but requiring longer curing times and more manual handling. Spray application is ideal for irregular surfaces and large areas, while cast-in-situ offers enhanced control for structural components and thickness variations.

Thermal Performance and Insulation Comparisons

Spray-applied hempcrete offers superior airtightness and more consistent insulation layers compared to cast-in-situ hempcrete, enhancing thermal performance by reducing thermal bridging. Cast-in-situ hempcrete's density provides better thermal mass, which stabilizes indoor temperatures but may have slightly lower R-values than the sprayed method. Both methods leverage hempcrete's natural insulating properties, but spray application delivers improved uniformity and faster installation times, optimizing overall energy efficiency.

Structural Strength and Load-Bearing Capacity

Spray-applied hempcrete offers improved uniformity and density, resulting in enhanced structural strength compared to cast-in-situ hempcrete, which can experience inconsistencies due to manual pouring. The spray method achieves better compaction and bonding around reinforcements, increasing load-bearing capacity in walls and structural elements. Cast-in-situ hempcrete, while simpler to execute, generally exhibits lower compressive strength and requires supplementary framing for significant load support.

Construction Speed and Labor Efficiency

Spray-applied hempcrete significantly accelerates construction speed by enabling rapid, continuous application directly onto formwork, reducing curing times compared to cast-in-situ hempcrete which requires manual layering and longer setting periods. Labor efficiency improves with spray-applied hempcrete through decreased physical strain and fewer laborers needed due to mechanized spraying equipment. Cast-in-situ hempcrete demands more skilled labor for consistent mixing and placement, resulting in higher labor costs and extended project timelines.

Environmental Impact and Sustainability Analysis

Spray-applied hempcrete reduces waste and energy consumption by minimizing material overuse and enabling faster installation compared to cast-in-situ hempcrete, which often requires more water and energy for curing. Cast-in-situ hempcrete offers enhanced structural integration but has higher embodied carbon due to formwork and prolonged curing times. Both methods utilize hemp's carbon-sequestering properties, but spray application delivers a more sustainable footprint through efficient resource use and reduced on-site emissions.

Cost Implications and Project Suitability

Spray-applied hempcrete offers reduced labor costs and faster application times compared to cast-in-situ hempcrete, making it ideal for large-scale or complex projects with tight schedules. Cast-in-situ hempcrete, while often more expensive due to longer curing times and formwork requirements, provides superior structural integration and customization for smaller or bespoke constructions. Project suitability depends on balancing budget constraints with desired construction quality and timeline efficiency.

Spray-Applied Hempcrete vs Cast-In-Situ Hempcrete Infographic

materialdif.com

materialdif.com