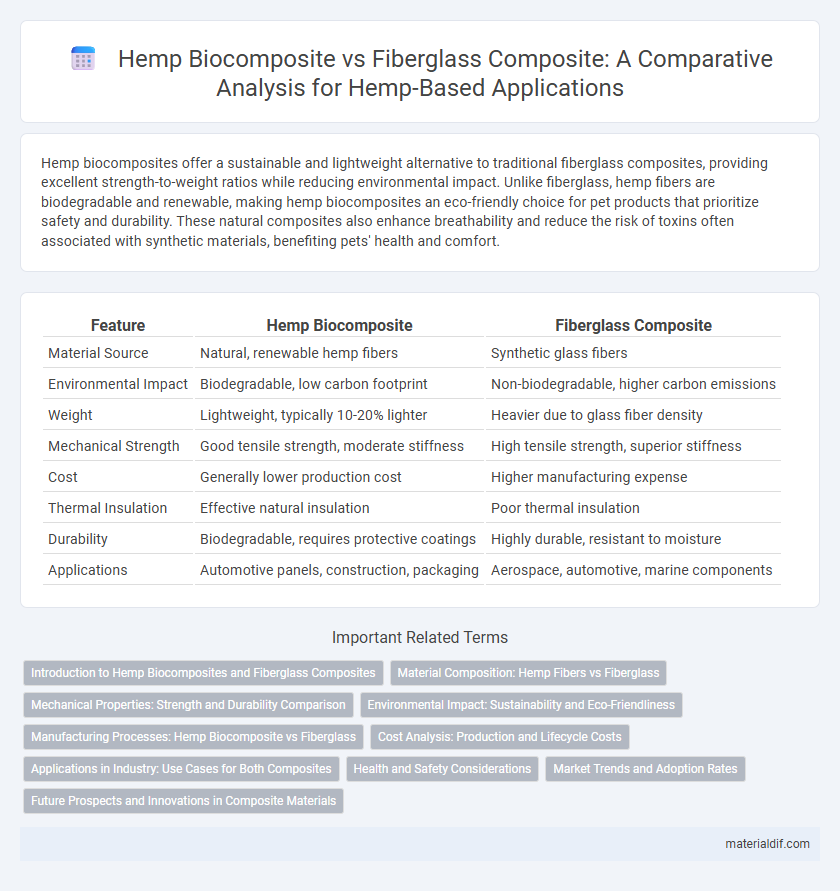

Hemp biocomposites offer a sustainable and lightweight alternative to traditional fiberglass composites, providing excellent strength-to-weight ratios while reducing environmental impact. Unlike fiberglass, hemp fibers are biodegradable and renewable, making hemp biocomposites an eco-friendly choice for pet products that prioritize safety and durability. These natural composites also enhance breathability and reduce the risk of toxins often associated with synthetic materials, benefiting pets' health and comfort.

Table of Comparison

| Feature | Hemp Biocomposite | Fiberglass Composite |

|---|---|---|

| Material Source | Natural, renewable hemp fibers | Synthetic glass fibers |

| Environmental Impact | Biodegradable, low carbon footprint | Non-biodegradable, higher carbon emissions |

| Weight | Lightweight, typically 10-20% lighter | Heavier due to glass fiber density |

| Mechanical Strength | Good tensile strength, moderate stiffness | High tensile strength, superior stiffness |

| Cost | Generally lower production cost | Higher manufacturing expense |

| Thermal Insulation | Effective natural insulation | Poor thermal insulation |

| Durability | Biodegradable, requires protective coatings | Highly durable, resistant to moisture |

| Applications | Automotive panels, construction, packaging | Aerospace, automotive, marine components |

Introduction to Hemp Biocomposites and Fiberglass Composites

Hemp biocomposites consist of natural hemp fibers combined with a polymer matrix, offering lightweight, renewable, and biodegradable alternatives to traditional materials. Fiberglass composites use glass fibers embedded in resin, providing high strength and durability but with higher environmental impact due to non-biodegradable components. Hemp biocomposites exhibit superior sustainability with competitive mechanical properties, making them increasingly popular in automotive and construction industries.

Material Composition: Hemp Fibers vs Fiberglass

Hemp biocomposites consist primarily of natural hemp fibers combined with biodegradable resins, offering a lightweight and renewable alternative to traditional composites. Fiberglass composites are made from fine glass fibers embedded in a polymer matrix, providing high strength and durability but relying on non-renewable materials. Hemp fibers deliver superior vibration damping and environmental benefits, while fiberglass composites excel in tensile strength and resistance to moisture and heat.

Mechanical Properties: Strength and Durability Comparison

Hemp biocomposites exhibit competitive tensile strength and impact resistance compared to traditional fiberglass composites, often reaching tensile strengths of 30-50 MPa with enhanced energy absorption capabilities. While fiberglass composites typically offer higher stiffness and superior durability in harsh environments, hemp biocomposites provide better biodegradability and reduced environmental impact without significantly compromising mechanical performance. Advances in hemp fiber treatment and matrix formulation continue to improve durability, making hemp biocomposites a viable sustainable alternative in automotive and construction industries.

Environmental Impact: Sustainability and Eco-Friendliness

Hemp biocomposites exhibit significantly lower environmental impact compared to fiberglass composites due to their renewable nature and carbon sequestration during hemp cultivation. Hemp fibers are biodegradable and require less energy-intensive processing, reducing greenhouse gas emissions and landfill waste. In contrast, fiberglass composites rely on non-renewable petroleum-based materials and resin matrices that generate toxic waste and are difficult to recycle, undermining sustainability efforts.

Manufacturing Processes: Hemp Biocomposite vs Fiberglass

Hemp biocomposites are manufactured through eco-friendly processes involving natural fiber extraction, drying, and combining with bio-based or synthetic resins, often using compression molding or extrusion methods that require less energy compared to fiberglass production. Fiberglass composites rely on energy-intensive processes, including glass fiber melting, weaving, and resin impregnation, typically employing hand lay-up, spray-up, or resin transfer molding techniques. The lower environmental impact and simpler manufacturing steps of hemp biocomposites make them a sustainable alternative in industries seeking greener materials without compromising strength and durability.

Cost Analysis: Production and Lifecycle Costs

Hemp biocomposites typically offer lower production costs compared to fiberglass composites due to the renewable nature and abundance of hemp fibers, which reduce raw material expenses and energy consumption during manufacturing. Lifecycle cost analysis reveals hemp biocomposites incur less environmental disposal and recycling costs, benefiting from biodegradability and lower toxic emissions. While fiberglass composites have higher durability, the overall cost-effectiveness of hemp biocomposites improves when factoring in sustainable sourcing and end-of-life management efficiencies.

Applications in Industry: Use Cases for Both Composites

Hemp biocomposites offer sustainable alternatives in automotive, construction, and consumer goods industries due to their lightweight, biodegradability, and excellent vibration dampening properties. Fiberglass composites dominate aerospace, marine, and high-performance sports equipment manufacturing because of their superior strength-to-weight ratio and resistance to corrosion. Both materials are increasingly integrated into automotive panels, building insulation, and durable consumer products, balancing environmental impact with performance demands.

Health and Safety Considerations

Hemp biocomposites offer significant health and safety advantages over fiberglass composites due to their natural, non-toxic fibers that reduce respiratory hazards during manufacturing and handling. Unlike fiberglass, which can cause skin irritation and release harmful airborne particles, hemp fibers are biodegradable and hypoallergenic, leading to safer workplace environments. The use of hemp biocomposites also minimizes long-term environmental health risks associated with synthetic materials and chemical emissions.

Market Trends and Adoption Rates

Hemp biocomposites are gaining traction in the sustainable materials market due to their biodegradability and lower environmental impact compared to fiberglass composites, which dominate traditional industries. Market trends show a rising adoption rate of hemp-based materials in automotive and construction sectors, driven by increasing regulatory pressures and consumer demand for eco-friendly alternatives. Industry reports predict hemp biocomposites will grow at a CAGR of over 15% through 2028, outpacing fiberglass composites in niche applications focused on sustainability.

Future Prospects and Innovations in Composite Materials

Hemp biocomposites demonstrate significant future potential due to their sustainability, lower carbon footprint, and biodegradability compared to traditional fiberglass composites. Innovations in fiber treatment and resin formulations are enhancing hemp composite strength and durability, making them viable alternatives in automotive and construction industries. Ongoing research into hybrid composites and nanotechnology integration is expected to further improve performance characteristics and expand hemp biocomposites' market applications.

Hemp biocomposite vs fiberglass composite Infographic

materialdif.com

materialdif.com