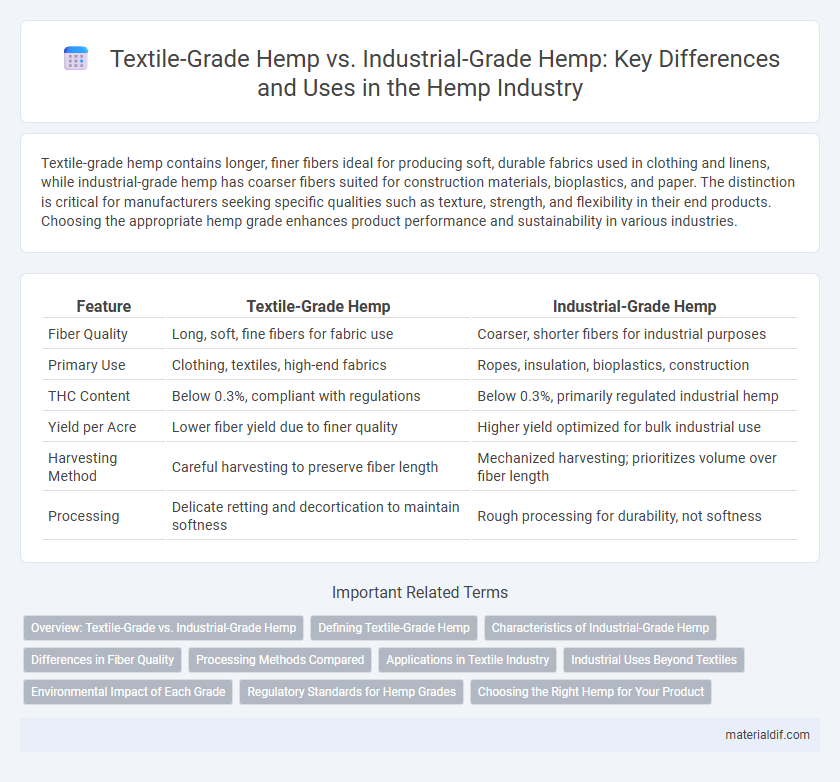

Textile-grade hemp contains longer, finer fibers ideal for producing soft, durable fabrics used in clothing and linens, while industrial-grade hemp has coarser fibers suited for construction materials, bioplastics, and paper. The distinction is critical for manufacturers seeking specific qualities such as texture, strength, and flexibility in their end products. Choosing the appropriate hemp grade enhances product performance and sustainability in various industries.

Table of Comparison

| Feature | Textile-Grade Hemp | Industrial-Grade Hemp |

|---|---|---|

| Fiber Quality | Long, soft, fine fibers for fabric use | Coarser, shorter fibers for industrial purposes |

| Primary Use | Clothing, textiles, high-end fabrics | Ropes, insulation, bioplastics, construction |

| THC Content | Below 0.3%, compliant with regulations | Below 0.3%, primarily regulated industrial hemp |

| Yield per Acre | Lower fiber yield due to finer quality | Higher yield optimized for bulk industrial use |

| Harvesting Method | Careful harvesting to preserve fiber length | Mechanized harvesting; prioritizes volume over fiber length |

| Processing | Delicate retting and decortication to maintain softness | Rough processing for durability, not softness |

Overview: Textile-Grade vs. Industrial-Grade Hemp

Textile-grade hemp features longer, finer fibers ideal for producing high-quality fabrics, whereas industrial-grade hemp includes coarser fibers better suited for applications like construction and bio-composites. The fiber length and cellulose content distinguish textile-grade hemp, enabling superior softness, flexibility, and durability in garments compared to the bulkier, more rigid industrial-grade variant. Understanding these distinctions informs optimal usage in sustainable fashion versus industrial manufacturing sectors.

Defining Textile-Grade Hemp

Textile-grade hemp is characterized by its long, strong fibers ideal for fabric production, distinguishing it from industrial-grade hemp primarily grown for seeds and CBD extraction. The fibers in textile-grade hemp are typically finer and more pliable, enhancing durability and comfort in clothing and upholstery. Cultivated under specific agricultural practices, textile-grade hemp emphasizes fiber quality and length, crucial for producing high-performance textiles.

Characteristics of Industrial-Grade Hemp

Industrial-grade hemp is characterized by its coarse fibers, high cellulose content, and low resin levels, making it ideal for durability and strength in industrial applications. It typically grows taller and more sparsely than textile-grade hemp, optimizing it for use in bioplastics, construction materials, and biofuel production. The stalks of industrial-grade hemp have a higher lignin content, providing rigidity essential for heavy-duty manufacturing processes.

Differences in Fiber Quality

Textile-grade hemp features longer, finer fibers with higher tensile strength, making it ideal for producing soft, durable fabrics used in clothing and upholstery. Industrial-grade hemp contains coarser, shorter fibers better suited for applications like rope, biocomposites, and insulation materials. The differing fiber qualities directly influence the end-use performance, texture, and processing methods of hemp-based products.

Processing Methods Compared

Textile-grade hemp undergoes a refined decortication process that carefully separates bast fibers from the woody core, preserving long, strong fibers ideal for fabric production. Industrial-grade hemp typically uses coarser processing methods such as mechanical chopping and milling, resulting in shorter fibers suited for composite materials and construction products. Advanced enzymatic retting in textile-grade hemp enhances fiber softness and fineness, distinguishing it from the bulkier, less processed fibers found in industrial-grade hemp.

Applications in Textile Industry

Textile-grade hemp is cultivated specifically for its strong, fine fibers ideal for producing high-quality fabrics, ropes, and clothing, while industrial-grade hemp is primarily grown for bulk biomass used in paper, plastics, and construction materials. In the textile industry, textile-grade hemp fibers offer superior durability, breathability, and biodegradability compared to synthetic alternatives, making them a preferred choice for sustainable fashion and eco-friendly textiles. Certified varieties like Futura 75 and Fedora 17 are commonly used in textile manufacturing due to their optimal fiber length and micronaire values, enhancing fabric softness and strength.

Industrial Uses Beyond Textiles

Industrial-grade hemp exhibits versatility beyond textile production, serving crucial roles in bioplastics, construction materials like hempcrete, and biofuel manufacturing. Its robust fiber content and chemical properties enable sustainable alternatives in automotive components and paper products. These industrial applications highlight hemp's potential to reduce reliance on traditional, non-renewable resources.

Environmental Impact of Each Grade

Textile-grade hemp typically requires fewer pesticides and less water due to its dense planting and selective breeding, resulting in a lower environmental footprint compared to industrial-grade hemp. Industrial-grade hemp, used primarily for construction and biofuel, often necessitates larger land areas and more intensive processing, which can increase soil degradation and energy consumption. Sustainable cultivation practices in both grades contribute to carbon sequestration and reduced greenhouse gas emissions, but textile-grade hemp is generally more eco-friendly due to its minimal chemical inputs and efficient resource use.

Regulatory Standards for Hemp Grades

Textile-grade hemp is primarily cultivated under stringent regulatory standards to ensure fiber quality, focusing on low THC content typically below 0.3% in compliance with international laws. Industrial-grade hemp regulations prioritize biomass yield over fiber fineness and may allow slightly higher THC thresholds depending on regional agricultural policies. Both grades must adhere to specific harvesting and processing guidelines established by agencies like the USDA and the European Commission to meet legal and market requirements.

Choosing the Right Hemp for Your Product

Textile-grade hemp features longer, finer fibers ideal for producing soft, durable fabrics used in clothing and home textiles. Industrial-grade hemp contains coarser fibers suited for manufacturing products like rope, bioplastics, and insulation materials. Selecting the right hemp variety depends on the fiber quality requirements and the end-use application of the product.

textile-grade hemp vs industrial-grade hemp Infographic

materialdif.com

materialdif.com