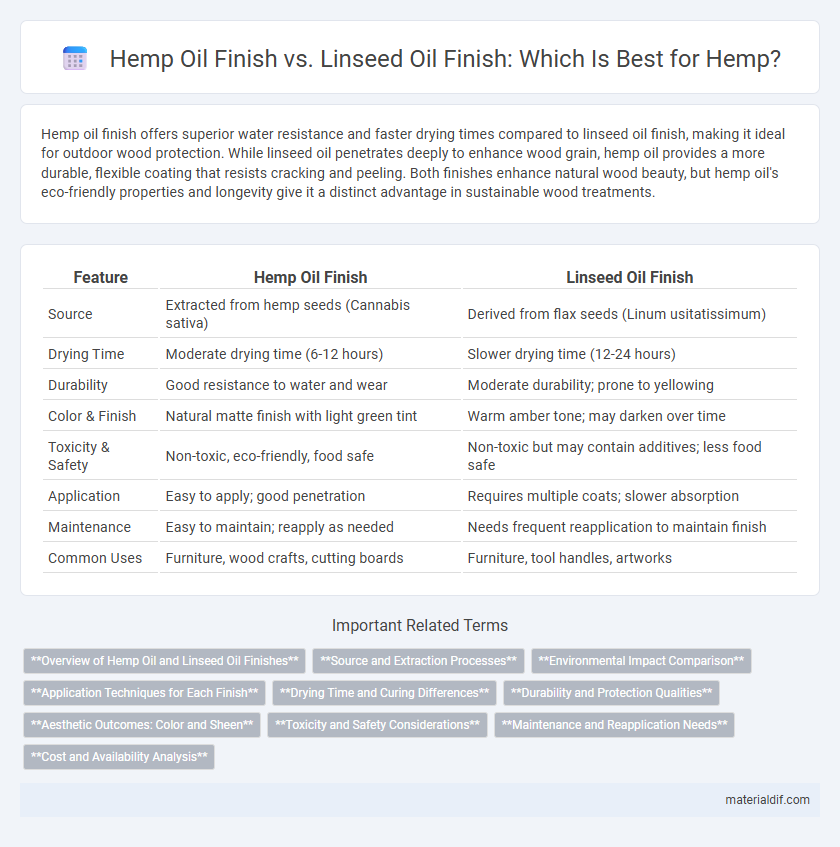

Hemp oil finish offers superior water resistance and faster drying times compared to linseed oil finish, making it ideal for outdoor wood protection. While linseed oil penetrates deeply to enhance wood grain, hemp oil provides a more durable, flexible coating that resists cracking and peeling. Both finishes enhance natural wood beauty, but hemp oil's eco-friendly properties and longevity give it a distinct advantage in sustainable wood treatments.

Table of Comparison

| Feature | Hemp Oil Finish | Linseed Oil Finish |

|---|---|---|

| Source | Extracted from hemp seeds (Cannabis sativa) | Derived from flax seeds (Linum usitatissimum) |

| Drying Time | Moderate drying time (6-12 hours) | Slower drying time (12-24 hours) |

| Durability | Good resistance to water and wear | Moderate durability; prone to yellowing |

| Color & Finish | Natural matte finish with light green tint | Warm amber tone; may darken over time |

| Toxicity & Safety | Non-toxic, eco-friendly, food safe | Non-toxic but may contain additives; less food safe |

| Application | Easy to apply; good penetration | Requires multiple coats; slower absorption |

| Maintenance | Easy to maintain; reapply as needed | Needs frequent reapplication to maintain finish |

| Common Uses | Furniture, wood crafts, cutting boards | Furniture, tool handles, artworks |

Overview of Hemp Oil and Linseed Oil Finishes

Hemp oil finish offers a natural, non-toxic alternative that enhances wood grain while providing water resistance and durability, favored for its eco-friendly properties and rapid drying time. Linseed oil finish, derived from flax seeds, is widely used for its deep penetration and ability to protect wood by forming a hard, long-lasting surface, though it typically requires longer curing periods. Both finishes improve wood aesthetics and protection but differ in environmental impact, drying speed, and maintenance needs, making them suitable for various woodworking and furniture applications.

Source and Extraction Processes

Hemp oil finish is derived from the seeds of the Cannabis sativa plant through cold pressing, preserving its natural nutrients and providing a non-toxic, eco-friendly coating. Linseed oil finish comes from the seeds of the flax plant and is extracted via cold pressing or solvent extraction, often requiring refinement to remove impurities. Both extraction methods impact the purity and drying properties of the oil finishes, influencing their durability and environmental footprint.

Environmental Impact Comparison

Hemp oil finish offers a significantly lower environmental impact than linseed oil finish due to its sustainable cultivation requiring less water, pesticides, and fertilizers. Hemp plants regenerate soil health by naturally replenishing nutrients, whereas flax crops for linseed oil may deplete soil over time. Additionally, hemp's rapid growth cycle allows for faster biomass renewal, promoting a more eco-friendly lifecycle compared to the longer growth period of flax used in linseed oil production.

Application Techniques for Each Finish

Hemp oil finish requires thorough application with a clean cloth or brush, allowing deep penetration into wood fibers for enhanced durability and natural water resistance. Linseed oil finish typically involves multiple thin coats applied with a brush or cloth, followed by extended drying times between coats to prevent tackiness and ensure a hard, protective surface. Both finishes benefit from light sanding between applications to improve adhesion and achieve a smooth, even finish.

Drying Time and Curing Differences

Hemp oil finish typically dries faster than linseed oil finish, often within 24 hours, while linseed oil may take several days to dry due to its thicker consistency and higher viscosity. The curing process of hemp oil results in a harder, more durable surface as it oxidizes and polymerizes more efficiently compared to linseed oil's slower, sometimes tacky curing stage. These differences in drying time and curing influence project timelines and final protective qualities for wood or hemp-based materials.

Durability and Protection Qualities

Hemp oil finish offers superior durability and enhanced protection against moisture and UV damage due to its high omega-3 fatty acid content, which strengthens the wood's resistance to environmental wear. Linseed oil finish, derived from flax seeds, provides a durable protective layer but tends to yellow over time and requires more frequent reapplications to maintain its protective qualities. Both finishes penetrate deeply into wood fibers, but hemp oil's natural antioxidant properties contribute to longer-lasting protection and increased resistance to cracking and peeling.

Aesthetic Outcomes: Color and Sheen

Hemp oil finish imparts a lighter, natural amber hue with a subtle matte sheen that enhances wood grain without overshadowing it, while linseed oil finish offers a richer, deeper golden-brown tone with a glossier sheen that intensifies the wood's natural textures. Hemp oil tends to preserve the wood's original color palette more faithfully, making it ideal for maintaining a fresh, organic look. Linseed oil's warmer coloration and higher gloss create a more pronounced, classic appearance favored in traditional woodworking.

Toxicity and Safety Considerations

Hemp oil finish is valued for its low toxicity and natural composition, making it safer for indoor use and contact with food surfaces compared to linseed oil finish, which can release volatile organic compounds (VOCs) and potentially contain residual solvents. Unlike linseed oil, which may pose risks of spontaneous combustion when improperly stored due to its drying properties, hemp oil has a lower risk profile and is less flammable. Hemp oil's non-toxic nature and biodegradability contribute to safer handling and environmental sustainability, reducing health hazards associated with prolonged exposure.

Maintenance and Reapplication Needs

Hemp oil finish requires less frequent maintenance and reapplication compared to linseed oil finish due to its natural resistance to water and UV damage. Linseed oil finish often needs reapplication every few months to maintain protection and appearance, as it tends to dry slower and can crack over time. Hemp oil's polymerizing properties ensure a durable, long-lasting finish that reduces upkeep efforts in wood care.

Cost and Availability Analysis

Hemp oil finish typically offers a more cost-effective option due to the abundant cultivation of hemp crops and lower processing expenses, making it widely available in many markets. Linseed oil finish, derived from flax seeds, tends to be slightly more expensive and less accessible depending on regional flax production and refining capacities. Both finishes have competitive price points, but hemp oil's sustainability and growing industrial demand influence its increasing availability and favorable cost structure.

Hemp oil finish vs Linseed oil finish Infographic

materialdif.com

materialdif.com