Unbleached hemp retains its natural color and fibers, preserving more nutrients and environmental benefits compared to bleached hemp, which undergoes chemical treatments to achieve a lighter appearance. The bleaching process can weaken fibers and introduce potentially harmful residues, reducing the material's eco-friendliness and durability. Choosing unbleached hemp supports sustainable practices and maintains the plant's original strength and texture for textile and industrial uses.

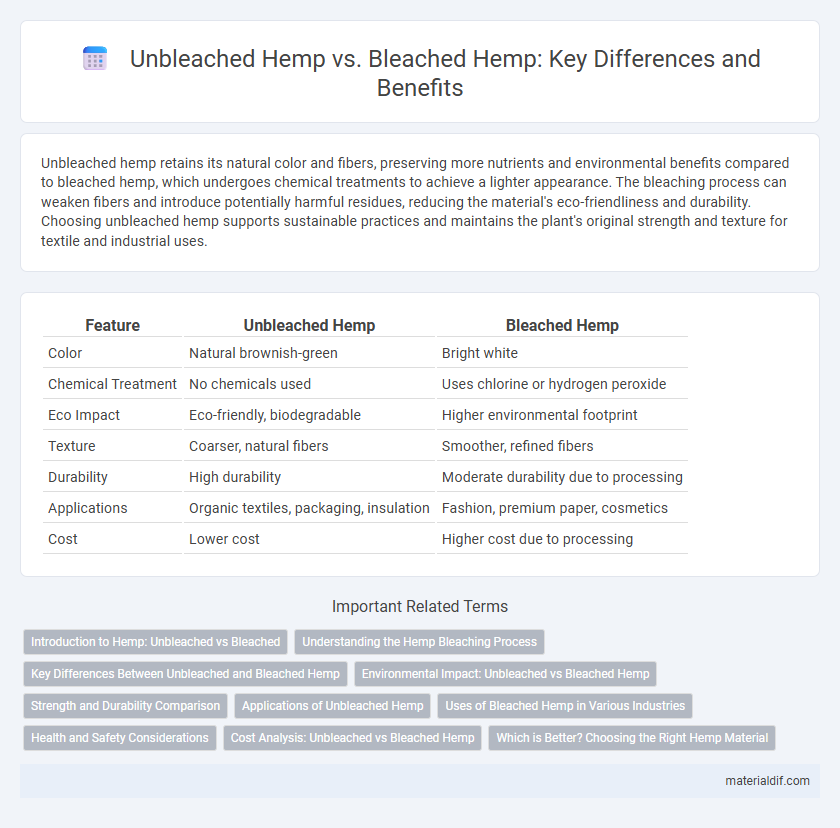

Table of Comparison

| Feature | Unbleached Hemp | Bleached Hemp |

|---|---|---|

| Color | Natural brownish-green | Bright white |

| Chemical Treatment | No chemicals used | Uses chlorine or hydrogen peroxide |

| Eco Impact | Eco-friendly, biodegradable | Higher environmental footprint |

| Texture | Coarser, natural fibers | Smoother, refined fibers |

| Durability | High durability | Moderate durability due to processing |

| Applications | Organic textiles, packaging, insulation | Fashion, premium paper, cosmetics |

| Cost | Lower cost | Higher cost due to processing |

Introduction to Hemp: Unbleached vs Bleached

Unbleached hemp retains its natural fibers and color, offering enhanced durability and environmental benefits due to minimal chemical processing. In contrast, bleached hemp undergoes chemical treatments to achieve a lighter appearance, which can weaken fibers and introduce potential toxins. Choosing unbleached hemp supports sustainability and maintains the plant's inherent strength and texture.

Understanding the Hemp Bleaching Process

Unbleached hemp retains its natural color and nutrients because it bypasses chemical bleaching, preserving eco-friendly properties and fiber strength. The hemp bleaching process involves treating fibers with chemicals like hydrogen peroxide or chlorine-based agents to achieve a lighter appearance but can weaken fibers and generate environmental pollutants. Understanding this process highlights the trade-off between aesthetic appeal and sustainable, durable hemp textile production.

Key Differences Between Unbleached and Bleached Hemp

Unbleached hemp retains its natural brown or greenish color, preserving more of its organic fibers and nutrients, while bleached hemp undergoes chemical treatment to achieve a cleaner, white appearance often desired for aesthetic purposes. The bleaching process can weaken hemp fibers and reduce their durability, whereas unbleached hemp fibers remain stronger and more environmentally friendly due to minimal processing. Differences in texture, strength, and environmental impact are crucial when selecting unbleached versus bleached hemp for textiles, paper, and biodegradable materials.

Environmental Impact: Unbleached vs Bleached Hemp

Unbleached hemp requires less chemical processing, significantly reducing water pollution and chemical runoff compared to bleached hemp, which often involves chlorine-based agents that harm aquatic ecosystems. The absence of bleaching chemicals in unbleached hemp also lowers energy consumption and greenhouse gas emissions during production. Choosing unbleached hemp supports a more sustainable textile industry by minimizing environmental degradation and promoting ecological balance.

Strength and Durability Comparison

Unbleached hemp retains its natural fibers, offering superior strength and enhanced durability compared to bleached hemp, which undergoes chemical processes that can weaken its fibers. The bleaching process often reduces the tensile strength and longevity of hemp textiles, making unbleached hemp more suitable for heavy-duty applications and sustainable products. Fiber integrity in unbleached hemp contributes to better resistance against wear, UV exposure, and environmental stressors, ensuring longer-lasting material performance.

Applications of Unbleached Hemp

Unbleached hemp retains its natural fibers and color, making it ideal for eco-friendly textile production, reusable packaging, and organic personal care products. Its durability and minimal chemical treatment appeal to sustainable fashion brands and zero-waste packaging solutions. The natural texture and strength of unbleached hemp also enhance applications in home goods such as rugs, upholstery, and insulation materials.

Uses of Bleached Hemp in Various Industries

Bleached hemp is widely used in industries such as textiles, paper manufacturing, and bioplastics due to its enhanced whiteness and smooth texture. The bleaching process improves fiber quality, making it ideal for high-end fabrics, specialty papers, and eco-friendly packaging solutions. This versatility allows bleached hemp to serve diverse applications, including sustainable fashion, luxury stationery, and biodegradable containers.

Health and Safety Considerations

Unbleached hemp retains its natural fibers and avoids chemical exposure, reducing the risk of skin irritation and respiratory issues often linked to bleached hemp products. Bleached hemp undergoes chemical treatments with chlorine or peroxide, which can leave harmful residues and compromise fabric safety, especially for sensitive individuals. Choosing unbleached hemp supports better indoor air quality and minimizes potential toxic exposure, making it a safer option for health-conscious consumers.

Cost Analysis: Unbleached vs Bleached Hemp

Unbleached hemp typically incurs lower production costs due to minimal chemical processing, resulting in a more eco-friendly and budget-conscious option for manufacturers. Bleached hemp involves additional steps, using chlorine or peroxide treatments that increase expenses and environmental impact. Cost efficiency analysis favors unbleached hemp for sustainable packaging and textile industries aiming to reduce overall expenditures.

Which is Better? Choosing the Right Hemp Material

Unbleached hemp retains its natural fibers and nutrients, offering superior environmental benefits and durability compared to bleached hemp, which undergoes chemical processing that can weaken fibers and introduce harmful residues. For sustainability and maintaining the plant's natural strength, unbleached hemp is generally the better choice, especially in applications like textiles and eco-friendly packaging. However, bleached hemp provides a softer, more uniform appearance, making it preferable for consumer products where aesthetics are prioritized over ecological impact.

Unbleached hemp vs Bleached hemp Infographic

materialdif.com

materialdif.com