Bast fiber extraction involves separating the long, strong fibers found in the outer layer of the hemp stalk, prized for textiles and rope due to their durability and flexibility. Core fiber extraction targets the woody inner core, which is coarser and commonly used in applications like building materials and bioplastics. Understanding the differences between bast and core fiber extraction is crucial for optimizing hemp processing techniques tailored to specific industrial uses.

Table of Comparison

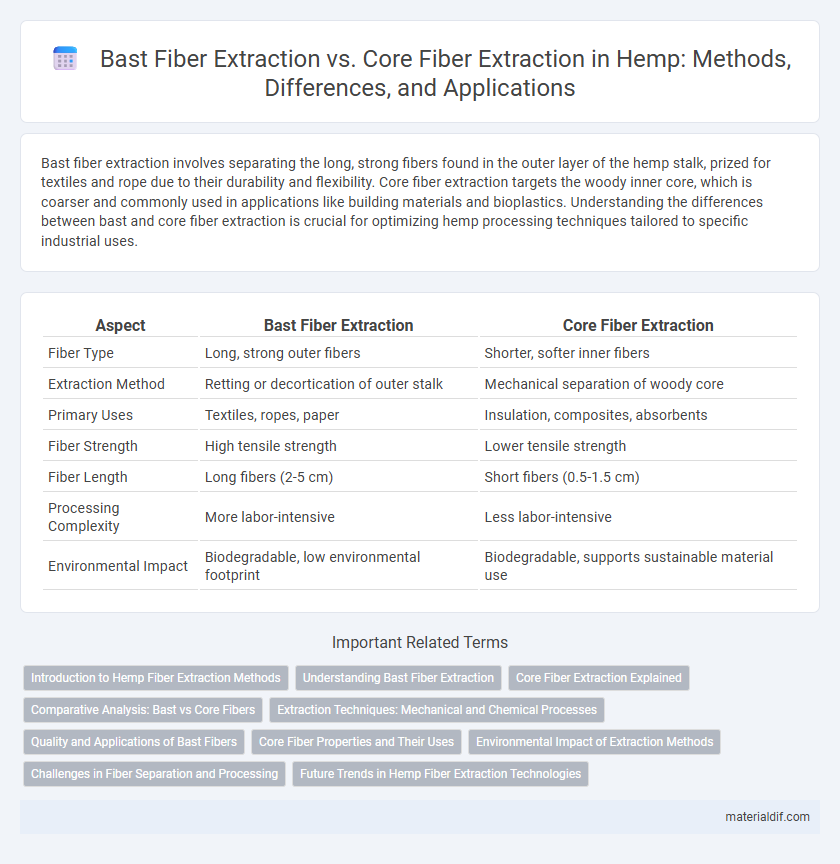

| Aspect | Bast Fiber Extraction | Core Fiber Extraction |

|---|---|---|

| Fiber Type | Long, strong outer fibers | Shorter, softer inner fibers |

| Extraction Method | Retting or decortication of outer stalk | Mechanical separation of woody core |

| Primary Uses | Textiles, ropes, paper | Insulation, composites, absorbents |

| Fiber Strength | High tensile strength | Lower tensile strength |

| Fiber Length | Long fibers (2-5 cm) | Short fibers (0.5-1.5 cm) |

| Processing Complexity | More labor-intensive | Less labor-intensive |

| Environmental Impact | Biodegradable, low environmental footprint | Biodegradable, supports sustainable material use |

Introduction to Hemp Fiber Extraction Methods

Hemp fiber extraction involves two primary methods: bast fiber extraction and core fiber extraction, each targeting different parts of the hemp stalk for distinct industrial uses. Bast fiber extraction isolates the outer fibrous layer of the hemp stalk, producing strong, long fibers ideal for textiles, ropes, and composites. Core fiber extraction processes the inner woody core, yielding shorter fibers suited for paper production, construction materials like hempcrete, and biofuel applications.

Understanding Bast Fiber Extraction

Bast fiber extraction involves separating the long, strong fibers from the outer layer of the hemp stalk, known as the bast, which is essential for producing high-quality textiles and ropes. This process typically uses retting methods, such as water, dew, or enzymatic retting, to break down the pectin that binds the bast fibers to the core, allowing for easier separation. Understanding bast fiber extraction is crucial for optimizing fiber strength, fineness, and yield, making it more valuable compared to core fiber extraction, which targets the softer inner hurd material for uses like composites and paper products.

Core Fiber Extraction Explained

Core fiber extraction from hemp involves separating the inner woody core, known as hurds, from the outer bast fibers through mechanical or chemical processes. This method yields short, coarse fibers primarily used for particleboards, animal bedding, and bioplastics, contrasting with the longer, stronger bast fibers used in textiles. The core's cellulose-rich composition makes it valuable for sustainable construction materials and absorbent products, highlighting its industrial versatility.

Comparative Analysis: Bast vs Core Fibers

Bast fiber extraction from hemp involves separating long, strong fibers located in the outer stalk, yielding higher tensile strength and durability ideal for textiles and composites. Core fiber extraction targets the softer, inner woody core, producing fibers with lower tensile strength but excellent insulation and absorbency properties. Comparative analysis reveals bast fibers are preferred for structural applications due to their mechanical robustness, while core fibers excel in acoustic and thermal insulation, highlighting distinct industrial uses based on fiber characteristics.

Extraction Techniques: Mechanical and Chemical Processes

Bast fiber extraction from hemp primarily involves mechanical processes such as decortication, where the outer fibrous layer is separated from the woody core using specialized machinery. Core fiber extraction often requires chemical treatments like alkaline retting or enzymatic processes to break down lignin and hemicellulose, facilitating the isolation of softer, inner fibers. Mechanical methods preserve fiber strength and are eco-friendly, while chemical processes enhance fiber purity but demand careful management of environmental impacts.

Quality and Applications of Bast Fibers

Bast fibers extracted from hemp plants are renowned for their strength, flexibility, and durability, making them ideal for high-quality textiles, ropes, and composite materials. Unlike core fibers, bast fibers possess superior tensile properties and finer texture, which contribute to enhanced performance in fashion and industrial applications. The extraction process preserves the bast fiber's cellulose content, resulting in a natural, breathable, and resilient material favored in sustainable fabric manufacturing and eco-friendly product design.

Core Fiber Properties and Their Uses

Core fiber extraction from hemp yields coarser and woodier fibers, characterized by higher lignin content and rigidity compared to softer bast fibers. These core fibers exhibit excellent insulation, absorbency, and durability, making them ideal for applications in construction materials such as hempcrete, bio-composites, and animal bedding. Their structural properties also enhance sound absorption and thermal regulation in eco-friendly building products.

Environmental Impact of Extraction Methods

Bast fiber extraction from hemp involves retting processes that can lead to water pollution if not properly managed, but produces high-quality fibers suitable for textiles and composites. Core fiber extraction, often mechanical, generates less wastewater and energy consumption but yields lower fiber quality, primarily used in insulation and biocomposites. Sustainable practices in both methods reduce environmental footprints, with innovations like enzymatic retting and decortication improving resource efficiency and minimizing chemical usage.

Challenges in Fiber Separation and Processing

Bast fiber extraction from hemp involves separating long, strong fibers from the outer bark, which requires precise retting and decortication techniques to avoid fiber damage and maintain quality. Core fiber extraction presents challenges due to the woody, less flexible inner core that demands more intensive mechanical processing for effective separation. Both methods face difficulties in achieving consistent fiber purity, minimizing environmental impact, and optimizing cost-efficient industrial-scale processing.

Future Trends in Hemp Fiber Extraction Technologies

Emerging technologies in hemp fiber extraction prioritize sustainable and efficient methods, with advanced decortication techniques improving bast fiber yield and quality while minimizing environmental impact. Innovations in enzymatic and microbial processing are enhancing core fiber extraction, enabling greater versatility for industrial applications such as biocomposites and textiles. Future trends emphasize integrating AI-driven machinery and closed-loop water systems to optimize fiber separation, reduce energy consumption, and boost economic viability across the hemp fiber supply chain.

Bast Fiber Extraction vs Core Fiber Extraction Infographic

materialdif.com

materialdif.com