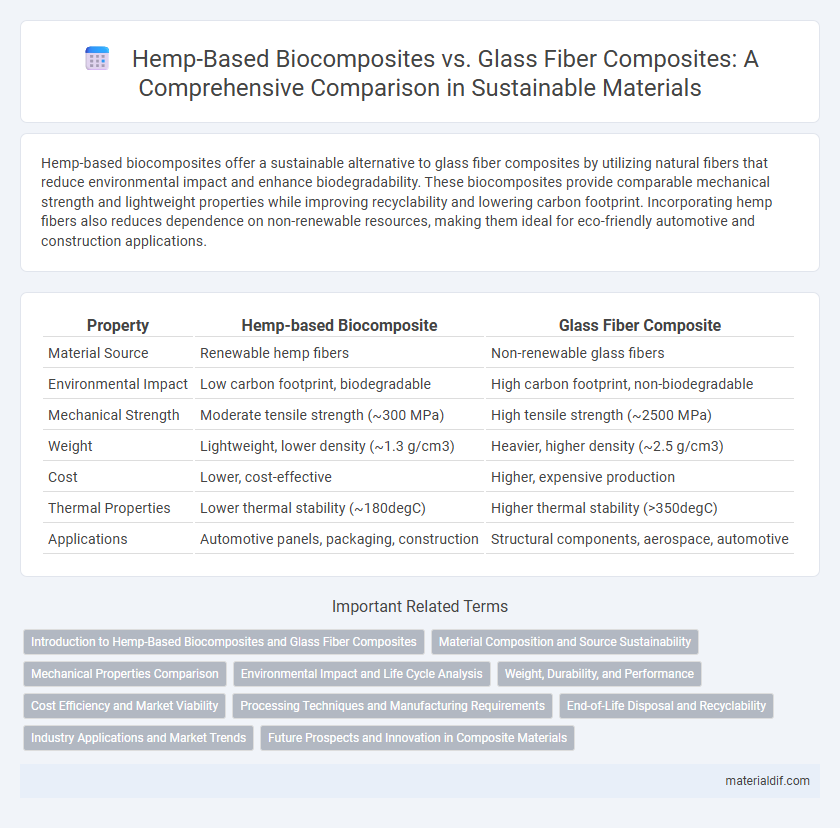

Hemp-based biocomposites offer a sustainable alternative to glass fiber composites by utilizing natural fibers that reduce environmental impact and enhance biodegradability. These biocomposites provide comparable mechanical strength and lightweight properties while improving recyclability and lowering carbon footprint. Incorporating hemp fibers also reduces dependence on non-renewable resources, making them ideal for eco-friendly automotive and construction applications.

Table of Comparison

| Property | Hemp-based Biocomposite | Glass Fiber Composite |

|---|---|---|

| Material Source | Renewable hemp fibers | Non-renewable glass fibers |

| Environmental Impact | Low carbon footprint, biodegradable | High carbon footprint, non-biodegradable |

| Mechanical Strength | Moderate tensile strength (~300 MPa) | High tensile strength (~2500 MPa) |

| Weight | Lightweight, lower density (~1.3 g/cm3) | Heavier, higher density (~2.5 g/cm3) |

| Cost | Lower, cost-effective | Higher, expensive production |

| Thermal Properties | Lower thermal stability (~180degC) | Higher thermal stability (>350degC) |

| Applications | Automotive panels, packaging, construction | Structural components, aerospace, automotive |

Introduction to Hemp-Based Biocomposites and Glass Fiber Composites

Hemp-based biocomposites consist of natural hemp fibers combined with a polymer matrix, offering lightweight, biodegradable alternatives with enhanced mechanical strength and reduced environmental impact compared to traditional composites. Glass fiber composites are composed of glass fibers embedded in a resin, providing high tensile strength, durability, and resistance to corrosion but exhibit higher weight and non-biodegradability. The growing demand for sustainable materials in automotive, construction, and aerospace industries has driven research into hemp-based biocomposites as eco-friendly substitutes for conventional glass fiber composites.

Material Composition and Source Sustainability

Hemp-based biocomposites primarily consist of natural hemp fibers combined with biodegradable resins, offering a renewable alternative to conventional materials. Hemp fibers are sourced from fast-growing, low-input crops that require minimal pesticides and water, significantly reducing environmental impact compared to glass fiber composites derived from energy-intensive mining and manufacturing processes. The sustainable cultivation and biodegradable nature of hemp-based composites make them a compelling choice for eco-conscious applications over non-renewable, resource-heavy glass fiber composites.

Mechanical Properties Comparison

Hemp-based biocomposites exhibit lower density and enhanced environmental sustainability compared to traditional glass fiber composites, making them ideal for lightweight applications. While glass fiber composites generally demonstrate superior tensile strength and stiffness, hemp biocomposites provide better impact resistance and energy absorption due to their natural fiber morphology. Mechanical property optimization of hemp composites through fiber treatment and matrix selection narrows the performance gap, promoting their use in automotive and construction industries.

Environmental Impact and Life Cycle Analysis

Hemp-based biocomposites demonstrate significantly lower environmental impact compared to glass fiber composites due to their renewable nature and reduced energy consumption during production. Life cycle analysis indicates hemp composites generate less carbon dioxide emissions and offer superior biodegradability, reducing long-term ecological footprint. These advantages make hemp biocomposites a sustainable alternative in automotive and construction applications.

Weight, Durability, and Performance

Hemp-based biocomposites offer a significant weight reduction compared to glass fiber composites, making them ideal for applications requiring lightweight materials. Although glass fiber composites generally provide higher durability and superior mechanical performance, hemp-based biocomposites deliver sufficient strength with improved biodegradability and reduced environmental impact. Advances in hemp fiber treatment and resin formulations continue to narrow the performance gap, promoting hemp biocomposites as sustainable alternatives in automotive and construction industries.

Cost Efficiency and Market Viability

Hemp-based biocomposites offer significant cost efficiency advantages over glass fiber composites due to lower raw material costs and reduced processing energy requirements, making them a sustainable alternative in manufacturing. Market viability of hemp composites is enhanced by increasing consumer demand for eco-friendly materials and rising regulatory support for biodegradable products in automotive, construction, and packaging industries. However, challenges such as variability in fiber quality and limited large-scale production infrastructure continue to impact the scalability of hemp-based composites compared to established glass fiber technologies.

Processing Techniques and Manufacturing Requirements

Hemp-based biocomposites utilize eco-friendly processing techniques such as compression molding and resin transfer molding, which require lower energy input compared to the high-temperature curing and extensive machinery used in glass fiber composite manufacturing. The manufacturing of hemp composites demands careful fiber treatment to enhance compatibility with bio-resins, reducing moisture absorption and improving mechanical properties. Glass fiber composites involve more complex curing cycles and stringent temperature controls to achieve desired structural performance, increasing production costs and environmental impact.

End-of-Life Disposal and Recyclability

Hemp-based biocomposites offer superior end-of-life disposal options compared to glass fiber composites due to their biodegradability and compostability, reducing landfill waste and environmental impact. Unlike glass fiber composites, which are challenging to recycle and often end up as non-degradable industrial waste, hemp biocomposites can be broken down naturally or repurposed through biological recycling processes. This enhanced recyclability positions hemp biocomposites as a sustainable alternative in industries prioritizing circular economy and reduced ecological footprint.

Industry Applications and Market Trends

Hemp-based biocomposites are gaining traction in automotive, construction, and consumer goods sectors due to their sustainability, lightweight properties, and biodegradability compared to traditional glass fiber composites. Market trends indicate increasing demand for eco-friendly materials driven by stringent environmental regulations and consumer preferences for green products. Industrial applications leverage hemp composites for cost-effective, high-strength alternatives that reduce carbon footprints and enhance product lifecycle sustainability.

Future Prospects and Innovation in Composite Materials

Hemp-based biocomposites offer significant advantages over glass fiber composites, including biodegradability, lower environmental impact, and renewable sourcing, making them highly attractive for sustainable material innovation. Advances in fiber treatment and resin compatibility are driving improvements in mechanical properties, positioning hemp composites as viable alternatives in automotive, construction, and packaging industries. Future research focuses on optimizing processing techniques and enhancing durability to expand the application scope and support circular economy initiatives.

Hemp-based Biocomposite vs Glass Fiber Composite Infographic

materialdif.com

materialdif.com