Bast fiber, derived from the outer bark of the hemp stalk, is known for its strength, flexibility, and durability, making it ideal for textiles, ropes, and biocomposites. Core fiber, found in the inner woody core or hurds, is more rigid and absorbent, commonly used in construction materials like hempcrete and animal bedding. Differentiating between bast and core fibers enhances the efficient utilization of hemp in various industrial applications.

Table of Comparison

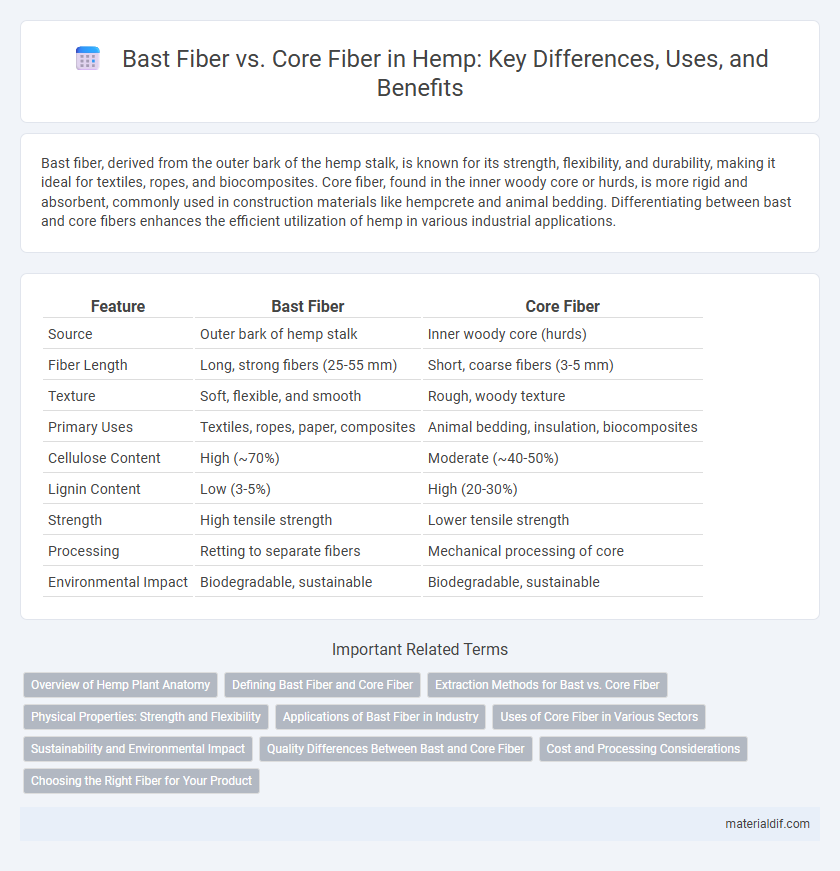

| Feature | Bast Fiber | Core Fiber |

|---|---|---|

| Source | Outer bark of hemp stalk | Inner woody core (hurds) |

| Fiber Length | Long, strong fibers (25-55 mm) | Short, coarse fibers (3-5 mm) |

| Texture | Soft, flexible, and smooth | Rough, woody texture |

| Primary Uses | Textiles, ropes, paper, composites | Animal bedding, insulation, biocomposites |

| Cellulose Content | High (~70%) | Moderate (~40-50%) |

| Lignin Content | Low (3-5%) | High (20-30%) |

| Strength | High tensile strength | Lower tensile strength |

| Processing | Retting to separate fibers | Mechanical processing of core |

| Environmental Impact | Biodegradable, sustainable | Biodegradable, sustainable |

Overview of Hemp Plant Anatomy

The hemp plant consists primarily of two types of fibers: bast fibers and core fibers. Bast fibers, found in the outer bark or phloem, are long, strong, and flexible, making them ideal for textiles, ropes, and biocomposites. Core fibers, located in the inner woody core or hurd, are shorter, softer, and more absorbent, commonly used in paper production, animal bedding, and construction materials such as hempcrete.

Defining Bast Fiber and Core Fiber

Bast fiber refers to the strong, flexible fibers extracted from the outer layer of the hemp stalk, known for their high tensile strength and durability, making them ideal for textiles, ropes, and biocomposites. Core fiber, also called hurd or shiv, comes from the woody inner core of the hemp stalk and is characterized by its lightweight, woody texture utilized in animal bedding, construction materials like hempcrete, and paper production. The differentiation between bast and core fibers is crucial for optimizing hemp processing and maximizing the plant's industrial applications based on fiber properties.

Extraction Methods for Bast vs. Core Fiber

Bast fiber extraction from hemp involves retting processes such as water, dew, or enzymatic retting to break down pectins and separate long, strong fibers from the outer stalk. Core fiber extraction employs mechanical decortication to crush and separate the woody core, yielding shorter, less flexible fibers ideal for applications like animal bedding or biocomposites. Efficient separation techniques directly influence fiber quality, with retting preserving tensile strength in bast fibers, while core fiber extraction emphasizes throughput and fiber purity.

Physical Properties: Strength and Flexibility

Bast fiber, derived from the outer layer of the hemp stalk, exhibits superior tensile strength and greater flexibility, making it ideal for textiles and rope manufacturing. Core fiber, found in the inner woody core, is less strong but possesses higher compressive resistance and rigidity, suitable for insulation and composite materials. The contrasting physical properties of bast and core fibers enable hemp to serve diverse industrial applications by balancing durability and structural support.

Applications of Bast Fiber in Industry

Bast fiber, derived from the outer layer of the hemp stalk, is prized for its strength, flexibility, and durability, making it ideal for textile manufacturing, including clothing, ropes, and carpets. Its natural resistance to pests and moisture enhances its suitability for composite materials in automotive and construction industries, where lightweight and sustainable alternatives are critical. Bast fiber also plays a significant role in producing high-quality paper and bioplastics, supporting eco-friendly industrial applications.

Uses of Core Fiber in Various Sectors

Core fiber, derived from the inner woody part of the hemp stalk, is predominantly utilized in sectors such as construction for insulation and composite boards, automotive industries for lightweight panels and soundproofing materials, and agriculture as mulch or soil conditioners. Its coarse texture and high lignin content make it ideal for durable, eco-friendly building materials and biodegradable packaging solutions. Furthermore, core fiber contributes to the production of biofuels and animal bedding, showcasing its versatility across multiple industrial applications.

Sustainability and Environmental Impact

Bast fiber, extracted from the outer layer of the hemp stalk, is prized for its durability and renewable qualities, requiring less water and pesticides compared to cotton, thereby minimizing environmental footprint. Core fiber, sourced from the inner woody core, is often used in biocomposites and insulation, offering excellent biodegradability and carbon sequestration properties that enhance sustainability. Utilizing both bast and core fibers maximizes hemp's resource efficiency, supporting circular economy principles and reducing waste in textile and construction industries.

Quality Differences Between Bast and Core Fiber

Bast fiber, derived from the outer layer of the hemp stalk, boasts superior strength, flexibility, and durability compared to the inner core fiber, making it ideal for textiles and high-quality composite materials. Core fiber, sourced from the inner woody core, is coarser, less flexible, and primarily used in insulation, animal bedding, and bioplastics. The distinct cell structure and chemical composition of bast fiber contribute to its enhanced tensile strength and finer texture, ensuring better performance in fabric production and industrial applications.

Cost and Processing Considerations

Bast fiber, derived from the hemp stalk's outer layer, commands higher market value due to its superior strength, fineness, and versatility in textiles and composites, though processing requires retting and decortication which increase labor and equipment costs. Core fiber, found in the inner woody core, is less expensive to process since it needs minimal retting, making it suitable for low-cost applications like animal bedding, insulation, and bio-composites. The cost-effectiveness of core fiber processing is offset by its lower fiber quality and limited end-use applications compared to more expensive and labor-intensive bast fiber processing.

Choosing the Right Fiber for Your Product

Bast fiber from hemp, derived from the outer stalk, offers superior strength, flexibility, and durability, making it ideal for textiles, ropes, and eco-friendly packaging. Core fiber, found inside the stalk, provides softness and absorbency, suitable for insulation, animal bedding, and biocomposites. Selecting the right fiber depends on product requirements: choose bast fiber for high-strength applications and core fiber for lightweight, cushioning solutions.

Bast fiber vs Core fiber Infographic

materialdif.com

materialdif.com